Chinese alpine rush fibers having good antibacterial performance and used for weaving

A technology of asparagus fiber and asparagus, which is applied in the textile field, can solve the problems of long time required and research of asparagus fiber, and achieve excellent antibacterial performance and good performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

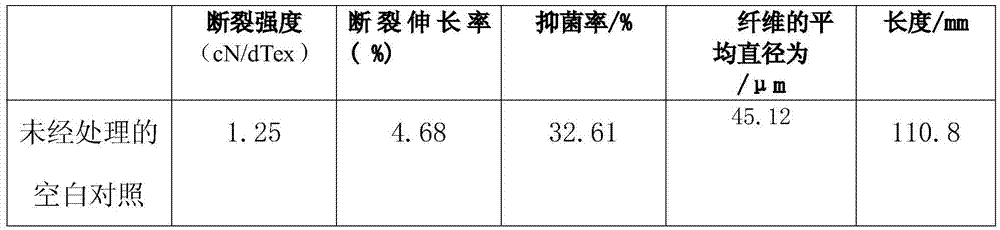

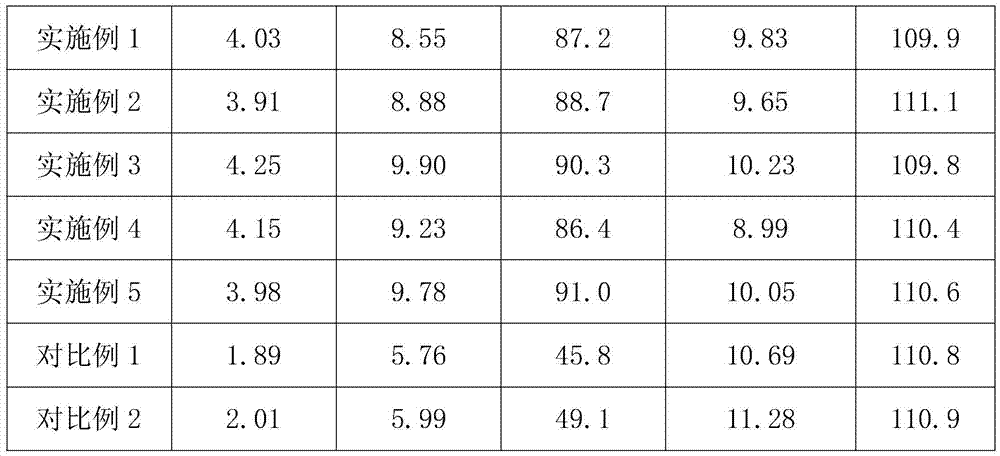

Examples

Embodiment 1

[0031] The preparation method of asparagus fiber for weaving with antibacterial performance is good, and its steps are as follows:

[0032] (1) Preprocessing:

[0033] Picking the year-old, high-maturity Asparagus, mechanically beat the harvested Asparagus to remove impurities, and then perform pretreatment. The treatment process is: malic acid 10g / L, acetic acid 2.5g / L, time 3h, temperature 80℃, liquor ratio 1:20;

[0034] (2) Microwave treatment:

[0035] Washing the pretreated asparagus fiber with water, heating to 80°C by microwave radiation;

[0036] (3) Enzyme treatment:

[0037] Equipped with enzyme solution: alkaline pectinase 2.2g / L, laccase 0.8g / L, neutral protease 0.6g / L, cellulase 0.2g / L;

[0038] The enzyme activity of alkaline pectinase is 350U / g, the enzyme activity of laccase is 3500u / g, the enzyme activity of neutral protease is 2800u / g, and the enzyme activity of cellulase is 2500u / g.

[0039] The processing parameters are: liquor ratio 1:20, time 65min,...

Embodiment 2

[0048] The preparation method of asparagus fiber for weaving with antibacterial performance is good, and its steps are as follows:

[0049] (1) Preprocessing:

[0050] Pick the year-old, high-maturity asparagus, mechanically beat the harvested asparagus to remove impurities, and then perform pretreatment. The treatment process is: malic acid 12g / L, acetic acid 2g / L, time 3h, temperature 80°C ℃, liquor ratio 1:20;

[0051] (2) Microwave treatment:

[0052] Washing the pretreated asparagus fiber with water, heating to 80°C by microwave radiation;

[0053] (3) Enzyme treatment:

[0054] Equipped with enzyme solution: alkaline pectinase 3.1g / L, laccase 0.5g / L, neutral protease 0.7g / L, cellulase 0.2g / L;

[0055] The enzyme activity of alkaline pectinase is 350U / g, the enzyme activity of laccase is 3500u / g, the enzyme activity of neutral protease is 2800u / g, and the enzyme activity of cellulase is 2500u / g.

[0056] The processing parameters are: bath ratio 1:20, time 55min, tem...

Embodiment 3

[0065]The preparation method of asparagus fiber for weaving with antibacterial performance is good, and its steps are as follows:

[0066] (1) Preprocessing:

[0067] Pick the year-old, high-maturity asparagus, mechanically beat the harvested asparagus to remove impurities, and then perform pretreatment. The treatment process is: malic acid 11g / L, acetic acid 2.4g / L, time 3h, temperature 80℃, liquor ratio 1:20;

[0068] (2) Microwave treatment:

[0069] Washing the pretreated asparagus fiber with water, heating to 80°C by microwave radiation;

[0070] (3) Enzyme treatment:

[0071] Equipped with enzyme solution: alkaline pectinase 2.5g / L, laccase 0.7g / L, neutral protease 0.6g / L, cellulase 0.2g / L;

[0072] The enzyme activity of alkaline pectinase is 350U / g, the enzyme activity of laccase is 3500u / g, the enzyme activity of neutral protease is 2800u / g, and the enzyme activity of cellulase is 2500u / g.

[0073] The processing parameters are: liquor ratio 1:20, time 60min, tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com