Online monitoring device for anode current distribution of aluminum electrolysis cell and monitoring method of online monitoring device

A technology of anode current and aluminum electrolytic cell, which is applied in the field of detection of anode current distribution of aluminum electrolytic cells, can solve the problems of difficulty in responding to changes in anode current distribution in a timely manner, manual effort, and low measurement accuracy, and achieve simple and reliable structure and monitoring methods , strong data support, solve the effect of manual effort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

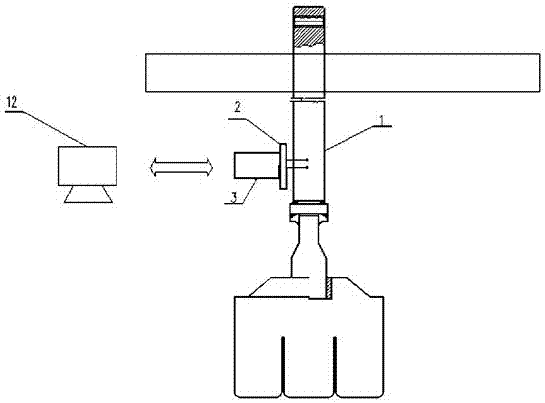

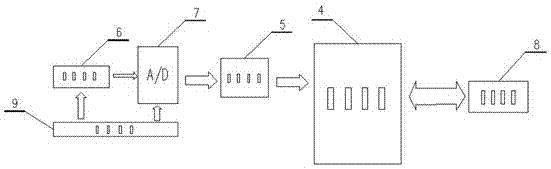

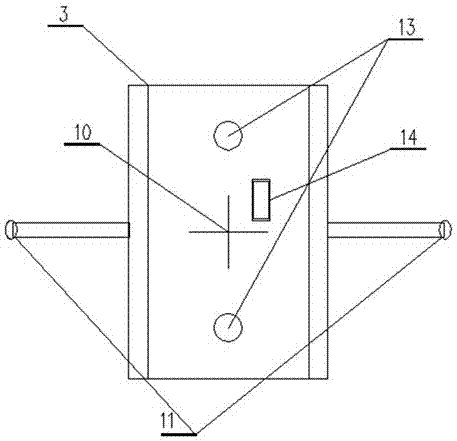

[0027] According to the number of aluminum electrolytic cell anode guide rods 1, such as 24 groups, the fixture 3 is installed on the aluminum electrolytic cell anode guide rod 1 in a complete set. When in use, the current measuring instrument 2 passes the collected voltage signal and temperature signal through the microprocessor 4. The processing is transformed into a current signal, and the current signal is stored in the storage module for backup. The current measuring instruments 2 on all the anode guide rods 1 are corrected in real time through the communication module 8 and the industrial computer 12 clock, and the current signals stored in the storage module at the same time point are used through the communication module 8 using aviation plugs with the function of preventing wrong insertion Connect for wired synchronous transmission to the industrial computer 12. The industrial computer 12 processes and analyzes the anode current signals at the same time point. Finall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com