Al-Si-Mg-Ti-Sr-Fe alloy material and preparation process thereof

An al-si-mg-ti-sr-fe, alloy material technology, applied in the field of Al-Si-Mg-Ti-Sr-Fe alloy material and its preparation, can solve the problem of mixed inclusions, shrinkage holes, and influence on the hub Mechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

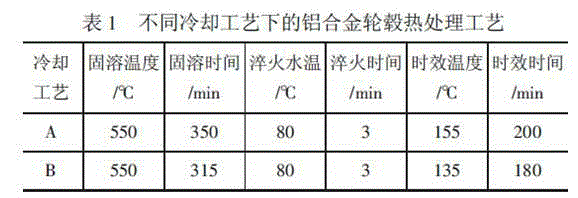

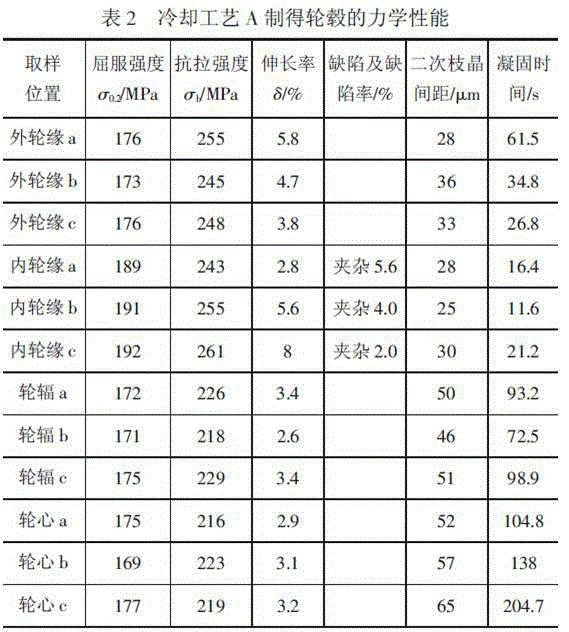

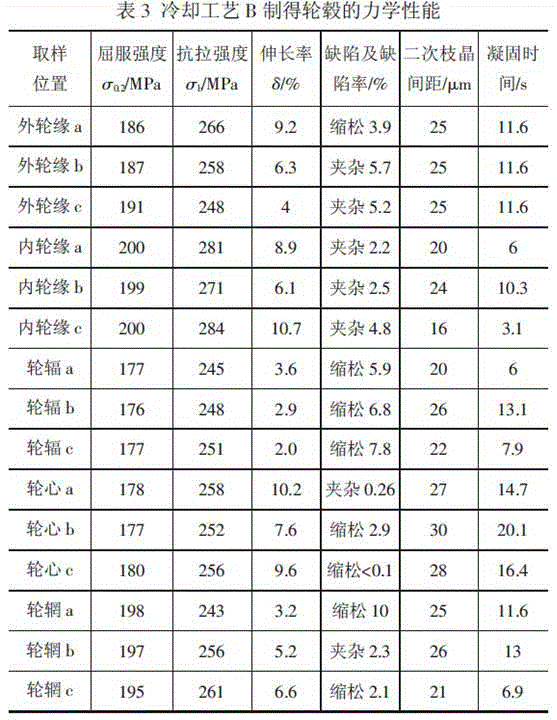

[0012] Using A356 aluminum ingots, adopting the method of low-pressure casting, adding appropriate amount of Al-Ti-B refiner and Al-10Sr modifier during the alloy melting process, the chemical composition (mass percentage) of the final fusion alloy is: 6.97% Si, 0.258%Mg, 0.128%Ti, 0.009%Sr, 0.131Fe, the total amount of remaining impurity elements <0.05%, and the balance Al. The experiment takes a Mercedes-Benz wheel hub as the research object, and adopts different cooling processes for the wheel hub to analyze the influence of different cooling methods on the defect distribution and mechanical properties of the wheel hub. The cooling method used in cooling process A is air cooling at the inner and outer rims, rims, and spokes, and water cooling at the center of the wheel to achieve sequential solidification; the cooling method used in cooling process B is all water cooling to achieve simultaneous solidification. Afterwards, the hub is subjected to solution and aging heat trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com