Blanking detection equipment applied to metal workpieces

A technology for testing equipment and metal parts, applied in the field of blanking testing equipment, can solve the problems of high labor intensity, low production efficiency, and many equipment, and achieve the effects of improving product qualification rate, increasing work efficiency, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

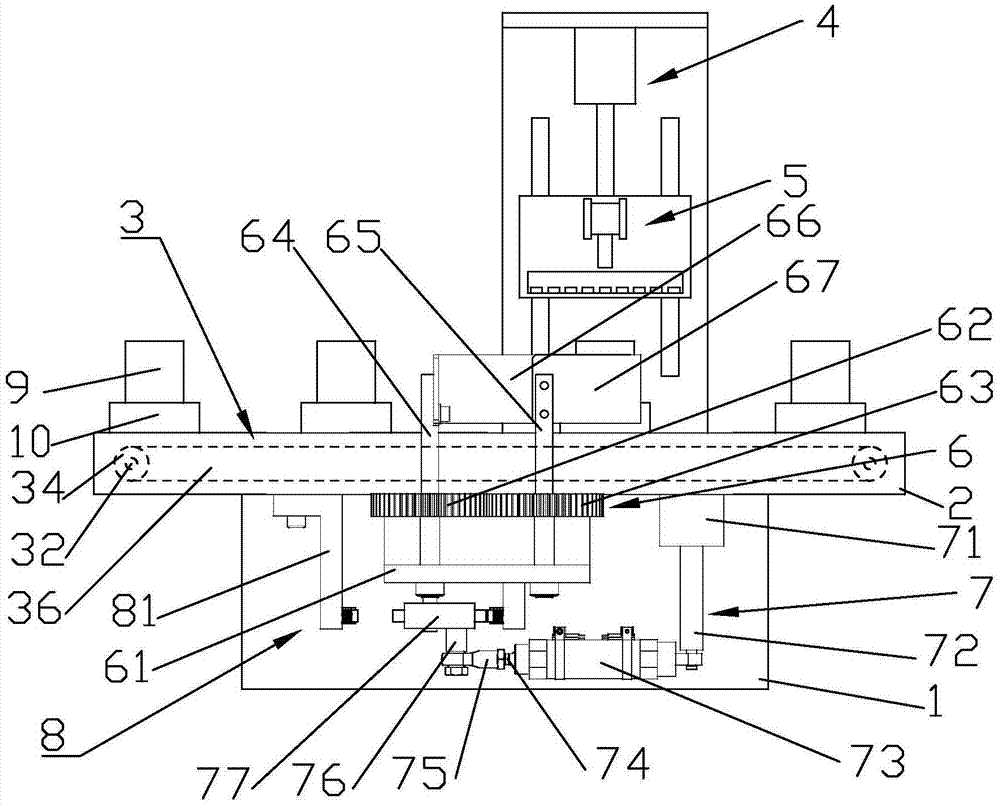

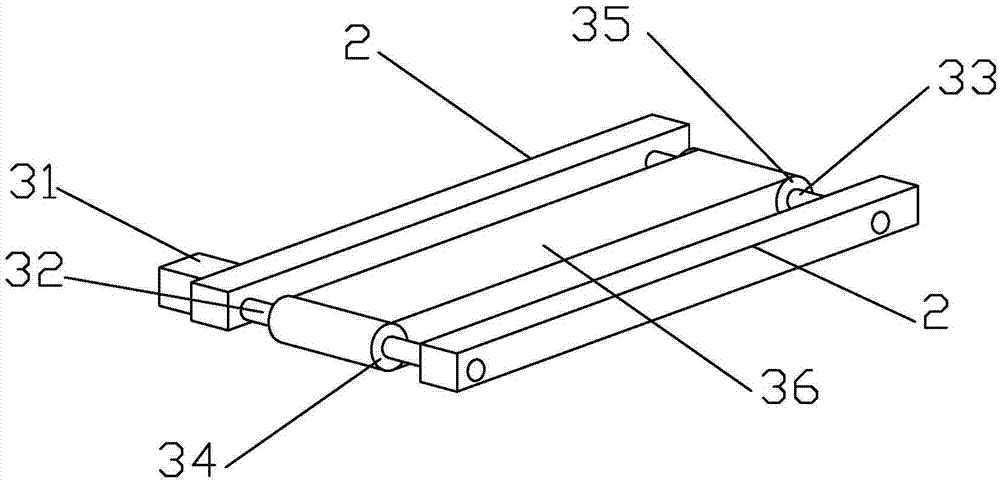

[0037] Such as Figure 1 to Figure 12 As shown, a blanking detection device applied to metal parts includes a frame 1 and a blanking platform 2, the blanking platform 2 is located on the frame 1, and a conveyor belt 36 is arranged between the blanking platforms 2, and the conveyor belt 36 A carrier 10 is arranged on the carrier 10, a metal piece 9 to be inspected is arranged on the carrier 10, and a conveyor belt 36 is connected with a feeding conveying device 3 . The inner side of the unloading platform 2 is provided with a detection device, the detection device includes a detection base plate 12, a detection stand 11, a camera assembly 5 and a lifting detection mechanism 4, the detection base plate 12 is installed on the unloading platform 2, and the detection base plate 12 is provided with a detection device. Stand 11, detection stand 11 is equipped with lifting detection mechanism 4, and lifting detection mechanism 4 is connected with camera assembly 5. The outside of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com