Automatic width controller for agricultural film production

A controller and wide-automatic technology, applied in the field of automatic controllers, can solve the problems that the film width cannot be dynamically and automatically measured, the measurement of finished products requires a lot of manpower, and the product quality cannot be guaranteed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

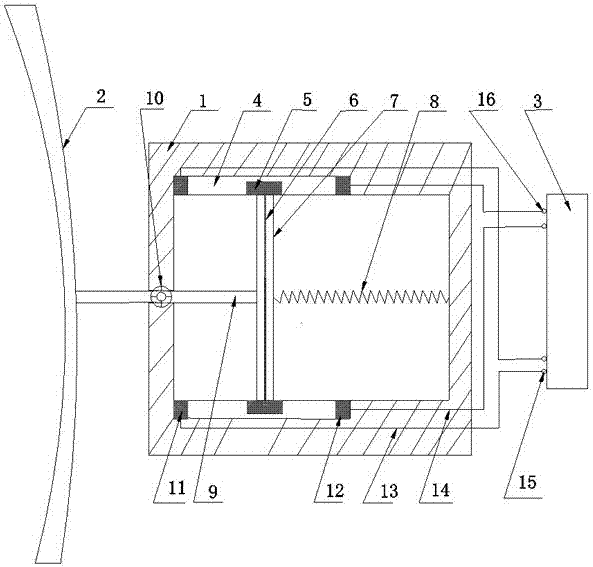

[0010] As shown in the figure, the automatic width controller for agricultural film production of the invention mainly includes a switch box 1, a test board 2, and a controller 3. It is characterized in that there are symmetrical rails 4 on the upper and lower walls of the switch box 1, and there are additional valve scales at both ends of the rails. Control the conductive contact block 11, lower the valve scale to control the conductive contact block 12, and there is a conductive slider 5 in the middle; the conductive slider 5 is connected by a conductor 6, and an insulator 7 is arranged outside the conductor 6; the middle of the insulator 7 and the test The plate 2 is connected with the connecting rod 9, and a spring 8 is arranged between the insulator 7 and the right wall of the switch; the valve scale control contact block 11 is increased, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com