A production device for PC foam boards for bags

A technology of foamed sheet and production equipment, which is applied in the production field of PC foamed sheet, which can solve the problems of affecting the smell of the sheet in the air environment, affecting the appearance of the sheet, uneven dispersion of foaming agent, etc., to achieve better appearance and light weight , better cell quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

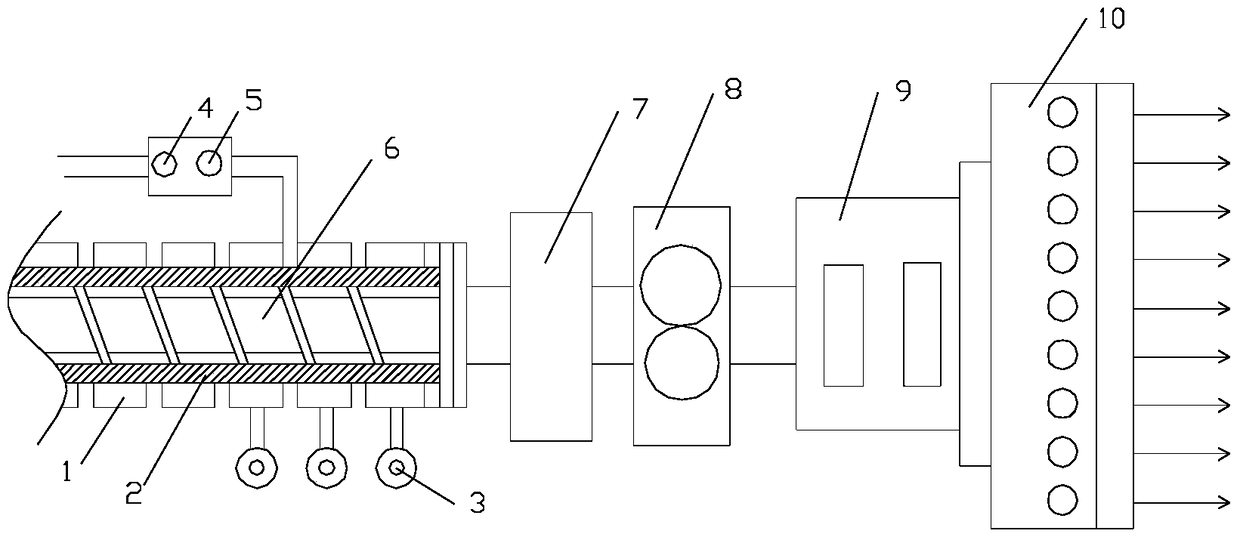

[0017] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 ;

[0018] A production device for PC foam sheets for luggage, including an extruder, a distributor, a die, a shaping roller, a tractor, a shearing machine, a first metering pump, a second metering pump, a pressure stabilizing valve, and a screen changer , raw materials (PC raw materials can be accompanied by pigments or other auxiliary materials) are extruded from the hopper through the extruder to the screen changer, the second metering pump, the distributor, and the die. After pressure relief and foaming in the die, the screen changer It can effectively filter impurities, and then enters the shaping roller from the die to shape, and then is pulled by the tractor to the shearing machine for shearing to make a finished product.

[0019] Among them, the extruder includes a barrel, a heating ring and a cooling fan are arranged on the bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com