A workbench device with a suction cup device for plate processing and its use method

A technology of plate processing and workbench, which is applied in the field of plate processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

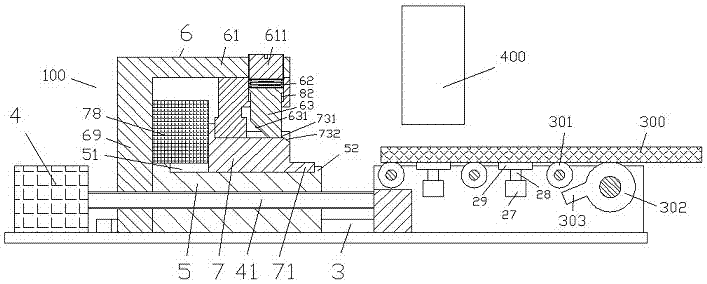

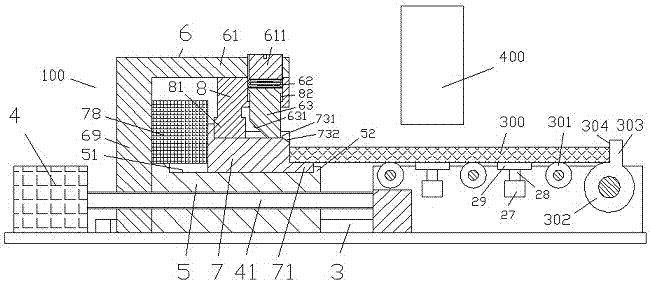

[0011] Combine below Figure 1-2 The present invention will be described in detail.

[0012] According to an embodiment, a workbench device with a suction cup device for sheet material processing includes a transmission support device fixedly connected to a frame, a locking drive motor 4 fixedly connected to the frame, and a locking drive motor 4 A driving screw 41 coupled with power, and a locking assembly 100 driven by the screw thread on the driving screw 41, wherein the locking assembly 100 is used to approach the plate 300 under the drive of the locking drive motor 4 The side of the locking assembly 100 is positioned and locked; the conveying support device is located on the side of the locking assembly 100 and is provided with a plurality of rotatable conveying rollers 301 to support the plate 300 and facilitate the external thrust of the plate 300 To move downward toward the locking assembly 100, the transmission support device is provided with a power-driven limiting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com