Workbench device used for board machining and provided with shock absorption and line pressing functions and use method of workbench device

A technology of pressing texture and sheet metal processing, which is applied in the field of sheet metal processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

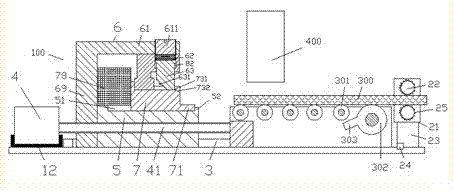

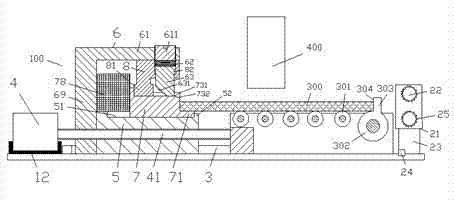

[0011] Combine below Figure 1-2 The present invention will be described in detail.

[0012] According to an embodiment, a workbench device capable of absorbing shock and embossing textures for plate processing includes a transmission support device fixedly connected to the frame, a locking drive motor 4 fixedly connected to the frame, and the The driving screw 41 that is power-connected to the locking drive motor 4 and the locking assembly 100 driven by the screw thread on the driving screw 41, a shock absorbing pad 12 is arranged between the locking driving motor 4 and the frame. In order to reduce the vibration force generated by the locking drive motor 4 during operation so as to ensure the stability of the transmission of the locking drive motor 4, wherein the locking assembly 100 is used to drive the locking drive motor 4 to The side of the plate 300 close to the locking assembly 100 is positioned and locked; the conveying support device is located on the side of the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com