Workbench device used for board machining and provided with heat dissipation function and use method of workbench device

A technology of plate processing and workbench, which is applied in the field of plate processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

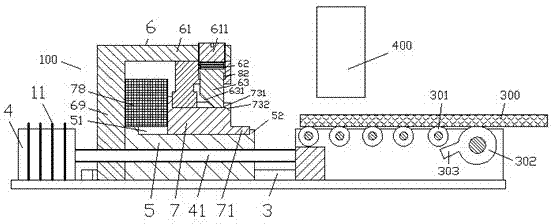

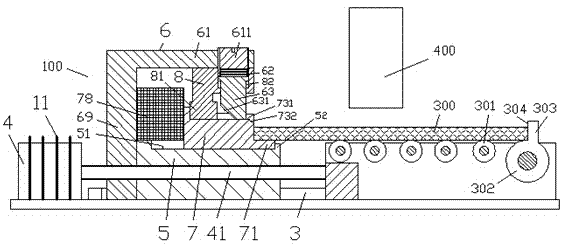

[0011] Combine below Figure 1-2 The present invention will be described in detail.

[0012] According to an embodiment, a heat-dissipating workbench device for plate processing includes a transmission support device fixedly connected to the frame, a locking drive motor 4 fixedly connected to the frame, and a power source connected to the locking drive motor 4 . The coupled drive screw 41, and the locking assembly 100 driven by the thread on the drive screw 41, the housing of the lock drive motor 4 is longitudinally provided with a plurality of heat dissipation fins 11 for locking the drive motor 4 The heat generated during operation is absorbed and dissipated, so as to prevent the locking drive motor 4 from burning due to excessive temperature during long-term operation, wherein the locking assembly 100 is used to drive the locking drive motor 4 to The side of the plate 300 close to the locking assembly 100 is positioned and locked; the conveying support device is located on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com