Cold rolling uncoiler guide sleeve repair method and device thereof

A repair method and guide sleeve technology are applied in the field of guide sleeve repair of a cold rolling decoiler and its device, which can solve the problems of similar hot working hardness, long maintenance period and high maintenance cost, and achieve long service life, avoid equipment failure, and easily effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1 The cold rolling decoiler guide sleeve repair method of the present invention comprises the following steps:

[0052]1) Disassemble the worn guide sleeve, and machine the inner hole of the guide sleeve on a lathe, with a processing amount of 1-2mm on one side;

[0053] 2) On the milling machine, the inner hole wall on both sides of the guide sleeve is processed at a position 200mm from the end;

[0054] 3) Process axial grooves at both ends of the guide sleeve on the slotting machine;

[0055] 4) Process the copper sleeve on the lathe to ensure the transition fit between the copper sleeve and the inner hole of the guide sleeve, the inner hole of the copper sleeve and the mandrel, and under the premise of meeting the stress requirements, the actual axial processing length of the copper sleeve is greater than the theoretically calculated copper sleeve. The minimum axial length of the sleeve (if there are multiple calculation results, take the theoretical max...

Embodiment 2

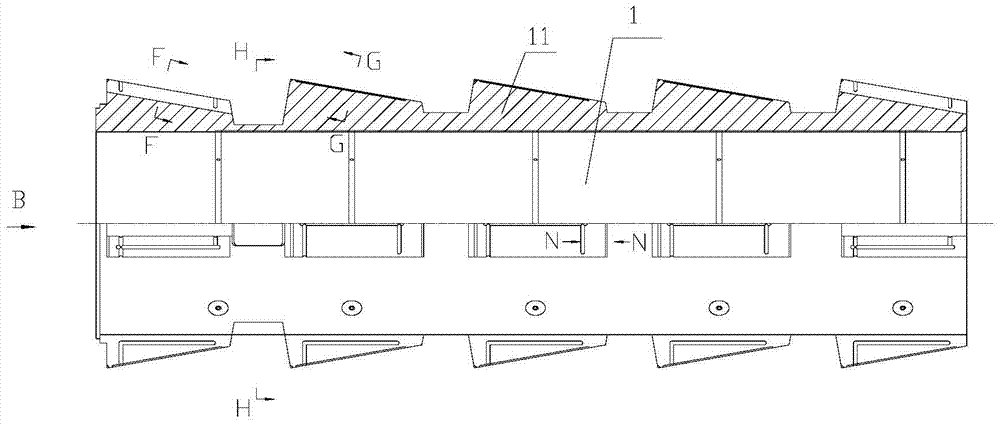

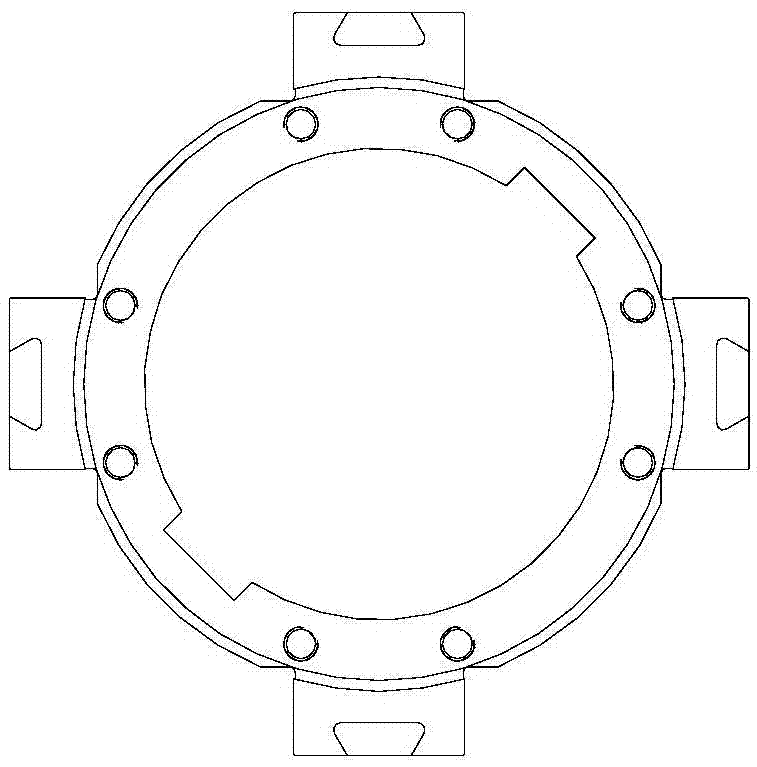

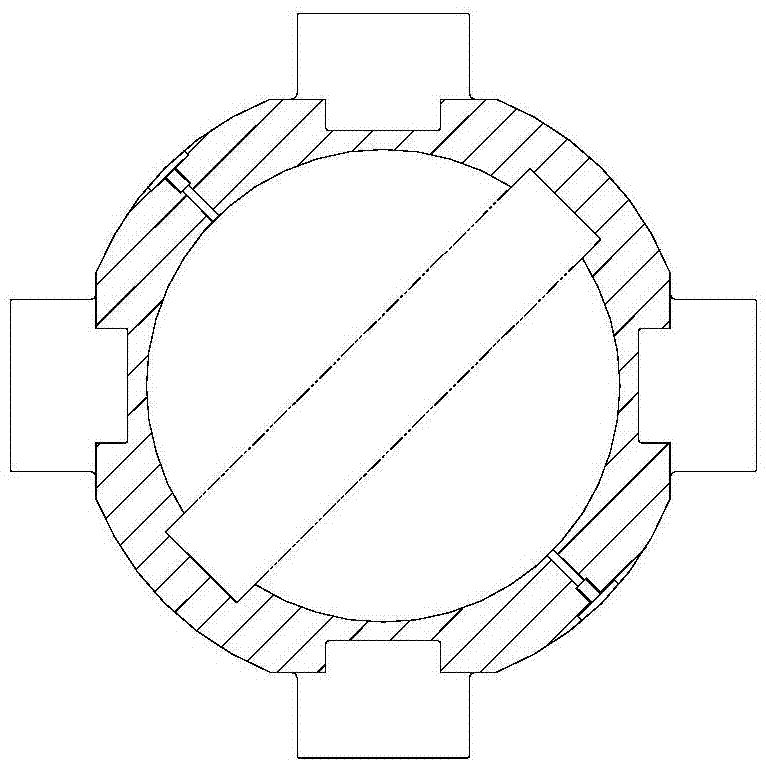

[0074] Embodiment 2 The device constructed according to the repair method of the present invention includes a guide sleeve 1, a mandrel 4 and a sector plate 3. The outer wall of the guide sleeve 1 is provided with a plurality of inclined wedges 11 with slopes. All The direction of the slope is the same, and each wedge is correspondingly installed with a fan-shaped plate 3, the fan-shaped plate 3 slides and fits with the guide sleeve 1 through the wedge 11, and the two ends of the guide sleeve 1 are respectively inlaid with copper sleeves 2 along the axial direction , the outer ring of the copper sleeve 2 is symmetrically provided with two engaging parts 21 for being stuck in the slot 12 of the guide sleeve, the copper sleeve 2 is transitionally fitted with the inner hole of the guide sleeve 1, and the mandrel 4 is inserted into the inner hole of the copper sleeve 2, the mandrel 4 is fixed to the copper sleeve 2 through the connecting key 41 axially arranged on the side wall of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com