Cleaning machine for threaded workpiece

A technology for cleaning machines and workpieces, applied in the field of cleaning machines, can solve the problems of long use time of the screw, work injury, accidental hand injury, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments of the description:

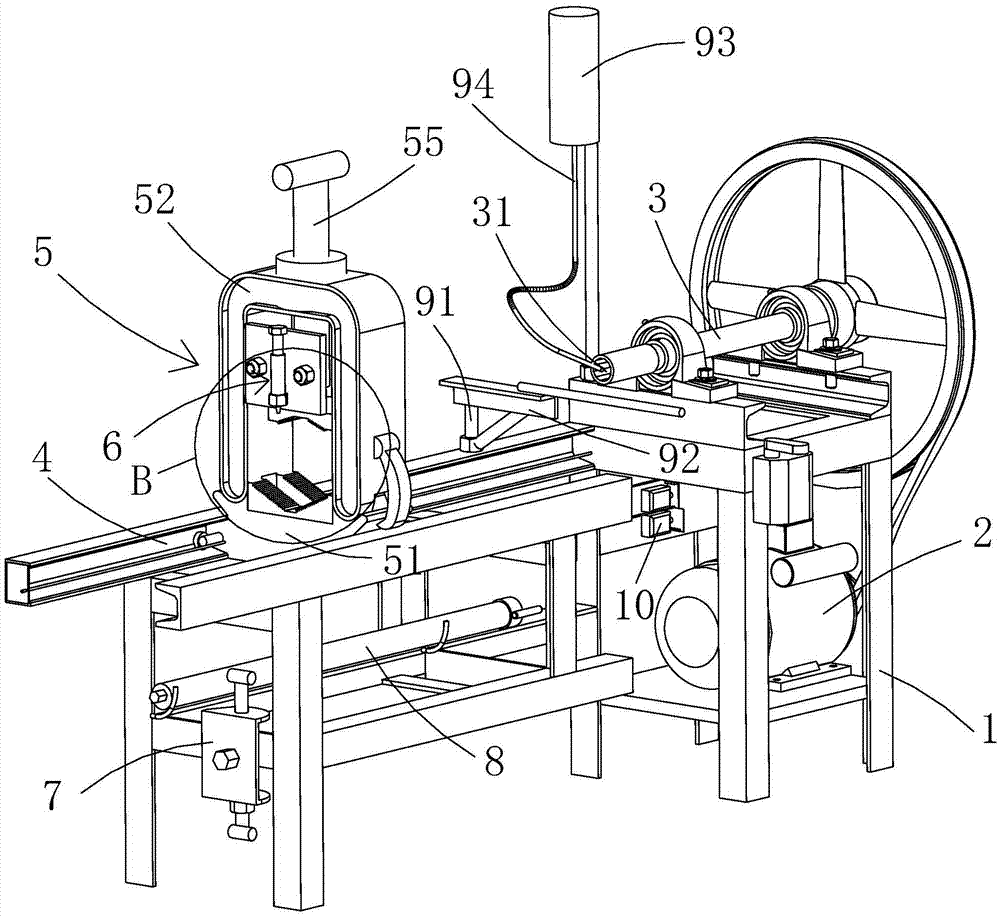

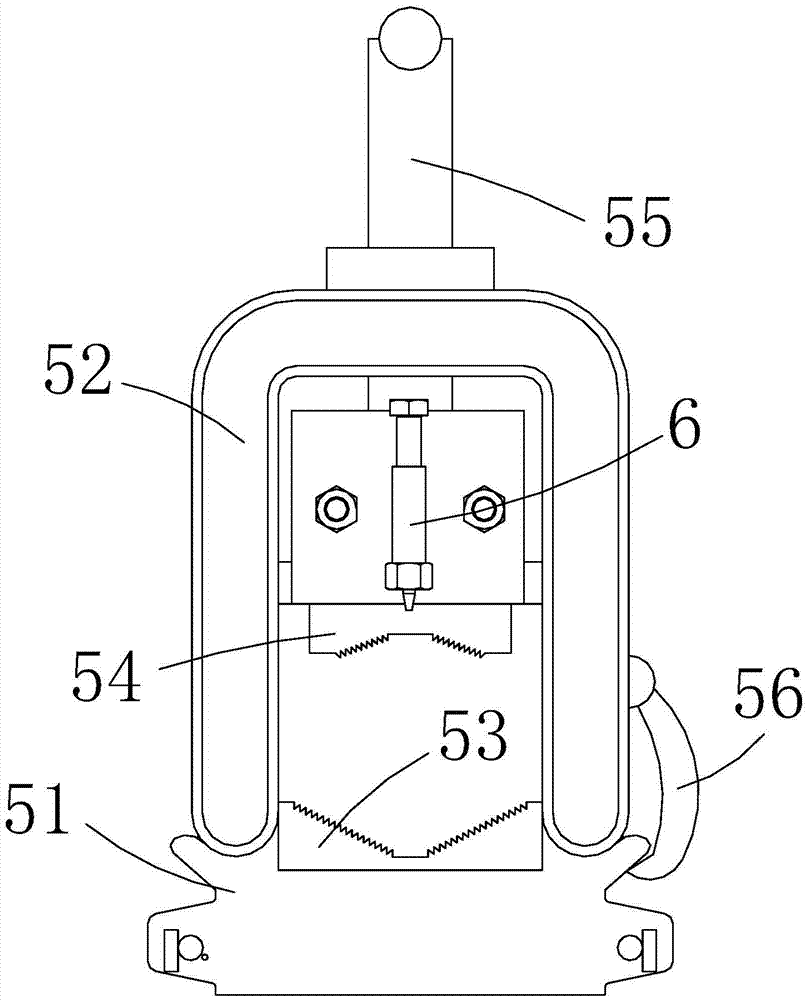

[0025] Such as Figures 1 to 11 Shown is a schematic diagram of an embodiment of a cleaning machine for threaded workpieces provided by the present invention.

[0026] A cleaning machine for threaded workpieces, which includes a frame 1, a rotating shaft 3 fixed on the frame 1 and driven by a power part 2, a connecting head arranged at the front end of the rotating shaft 3 and matched with the workpiece to be cleaned, and On the frame 1 at the front side of the rotating shaft 3 and the extending direction is parallel to the rail 4 of the rotating shaft 3 and the mobile base 5 that slides on the rail 4 and positions the nuts that are screwed on the workpiece to be cleaned.

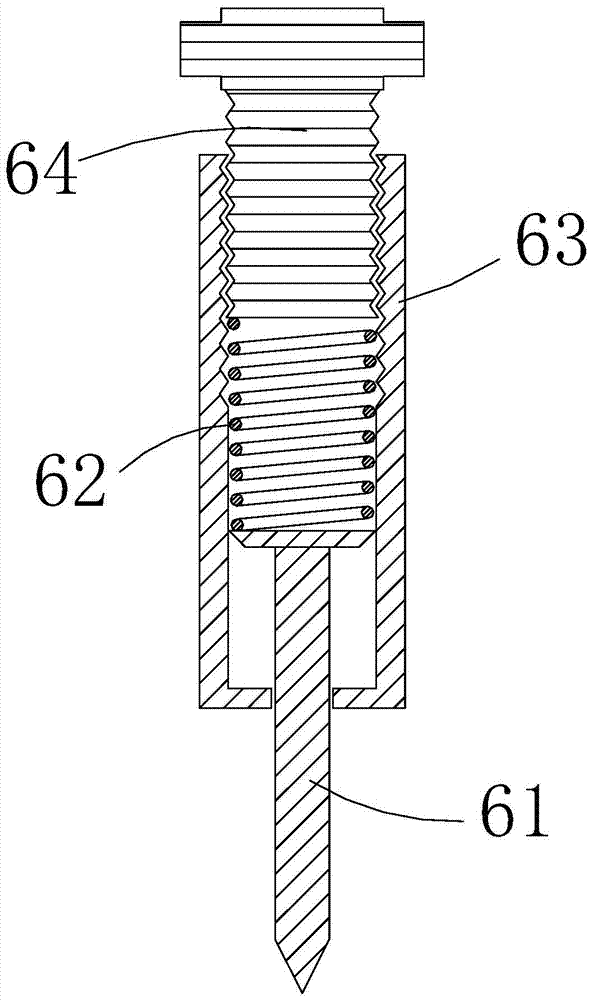

[0027] The mobile base 5 is also provided with a cleaning assembly 6 with a tip, and the tip of the cleaning assembly 6 presses against the threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com