Noodle maker capable of rapidly making noodles

A noodle machine and noodle technology, applied in the directions of dough extruder, mixing/kneading with vertical installation tools, etc., can solve the problems of difficulty in cooking, affecting the taste, and breaking the die, so as to avoid inconsistency in thickness and improve the quality of production. Face success rate, avoid the effect of excessive temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

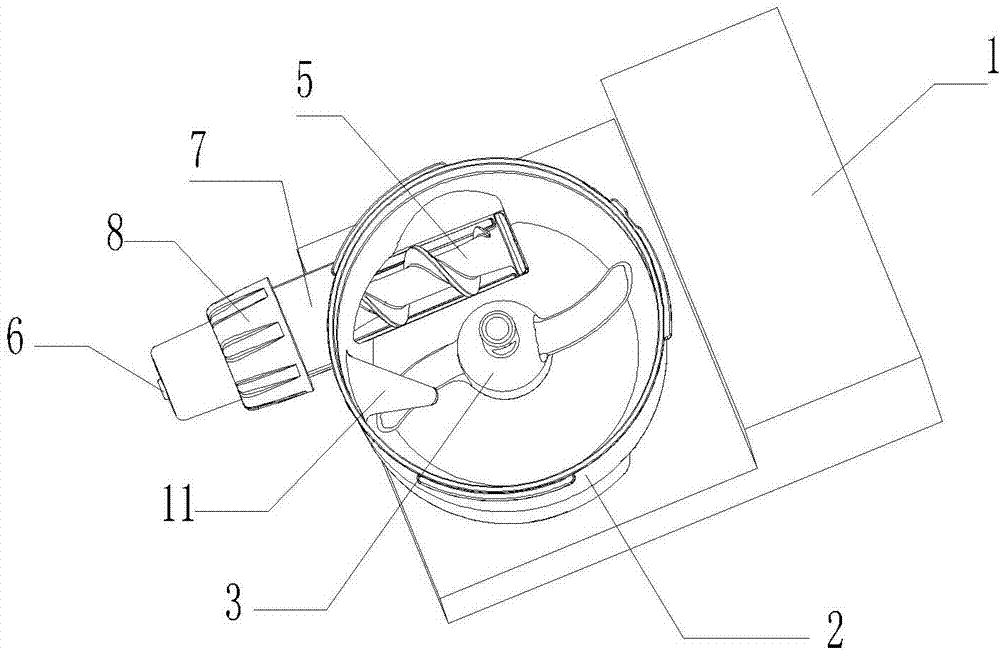

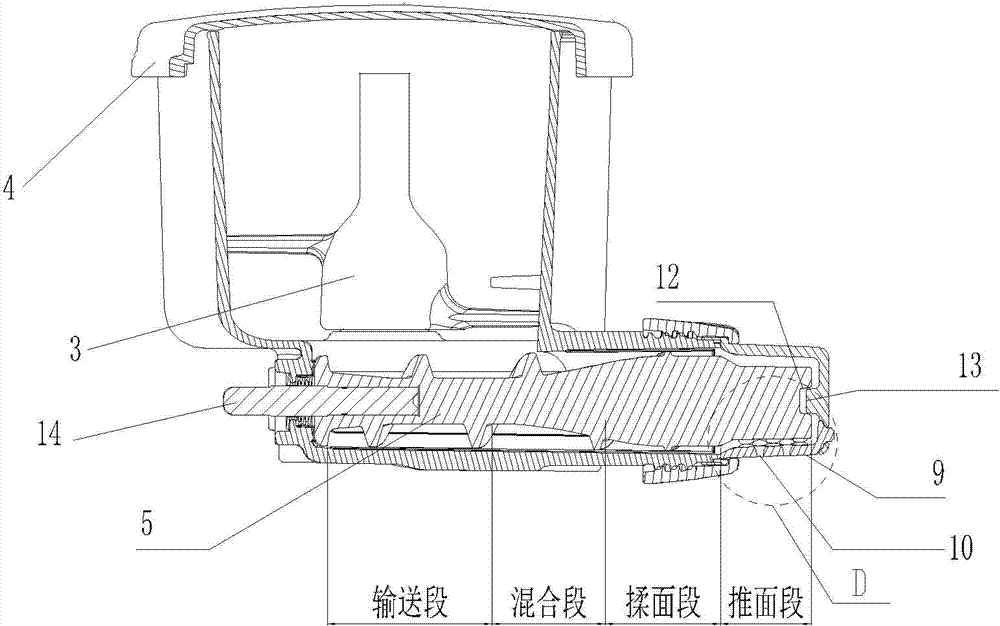

[0036] Such as figure 1 , figure 2As shown, a fast noodle machine is used to knead flour and water into dough and extrude it into noodles. It includes a main engine 1 with a motor, a stirring assembly and an extruding assembly. The stirring assembly includes a stirring cup 2 and a stirring rod 3 , a stirring chamber is formed in the stirring cup 2, the stirring cup 2 is provided with a top cover 4, the top cover 4 is rotatably matched with the stirring cup 2, and the extruding assembly includes a screw 5, a die head 6 and a noodle extruding cylinder 7, a noodle extruding cavity is formed in the noodle extruding cylinder 7, the extruding assembly is placed horizontally on the side of the main machine 1, and the die head 6 is installed on the The end of the extruding cylinder 7, the locking member 8 is threadedly connected with the extruding cylinder 7, the die head 6 includes an inner peripheral surface cooperating with the screw rod 5 and a molding area 9 positioned at the l...

Embodiment 2

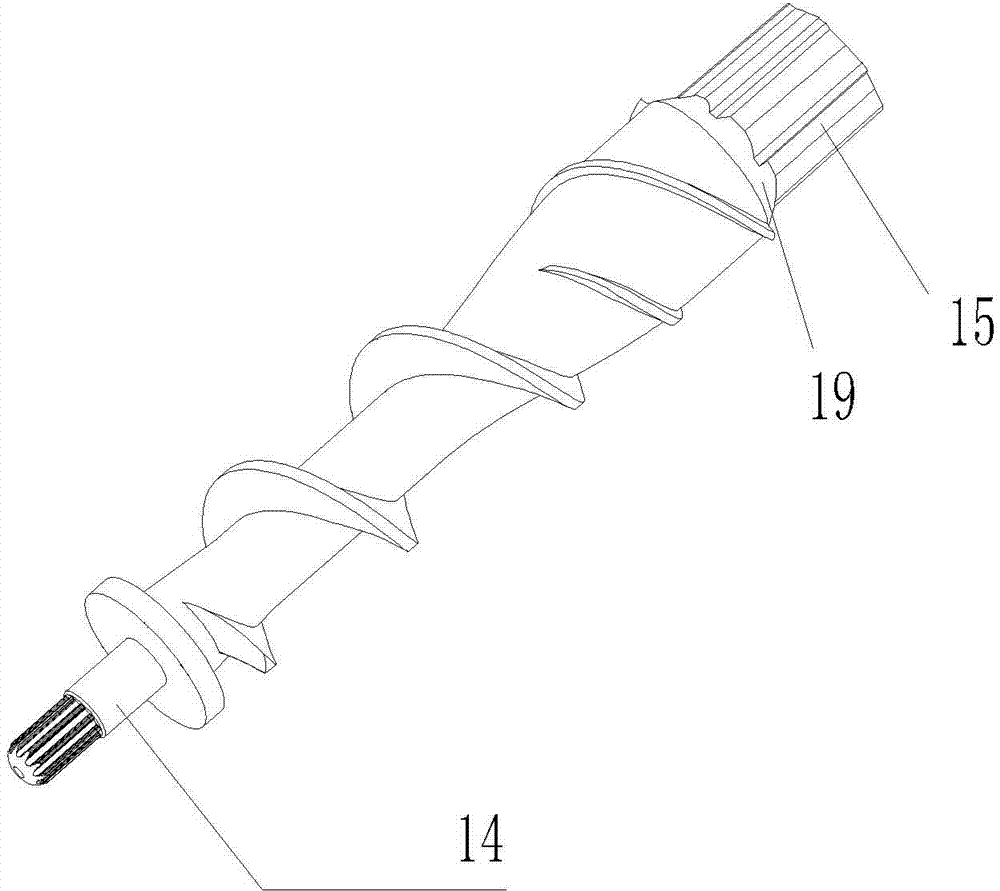

[0054] Such as Figure 7 , Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that: the push face teeth 15 are helical teeth, and are arranged on different planes from the central axis of the screw rod 5, and the helix angle of the helical teeth is θ, where 0°< θ≤45°. When θ=0°, the rotation of the pushing face section does not generate axial force. As the angle θ increases, the axial force increases gradually, while the tangential force and radial force become smaller. The advantage of this setting is that the helical teeth make the area of the dough that is pushed correspondingly larger, so that during the screw rod 5 rotating one revolution, the helical teeth have more effective pushing area per unit time than the straight teeth, which improves the noodle forming speed and makes Noodles are shaped more quickly, which speeds up the entire noodle making process. When θ is greater than 45°, the radial force generated is not enough to push the do...

Embodiment 3

[0056] Such as Figure 9 As shown, the difference between this embodiment and Embodiment 1 is that the pushing surface section includes a driving boss 21, and the cross section of the driving boss 21 is a regular polygon, which is a regular hexagon in this embodiment. A surface pushing sleeve 22 is arranged on the boss 21, the surface pushing sleeve 22 is hollowly arranged, and is detachably matched with the driving boss 21, and the surface pushing teeth 15 are arranged on the outer peripheral surface of the surface pushing sleeve 22 . The advantage of such setting is: through the detachable cooperation of the noodle pushing sleeve 22, it is more convenient to make noodles, such as when the water surface ratio is different, different noodle pushing sections can be replaced to make it suitable for different water surface ratios. , through the disassembly of the push face sleeve 22, the replacement of the face facing downward and the face facing forward can also be realized. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com