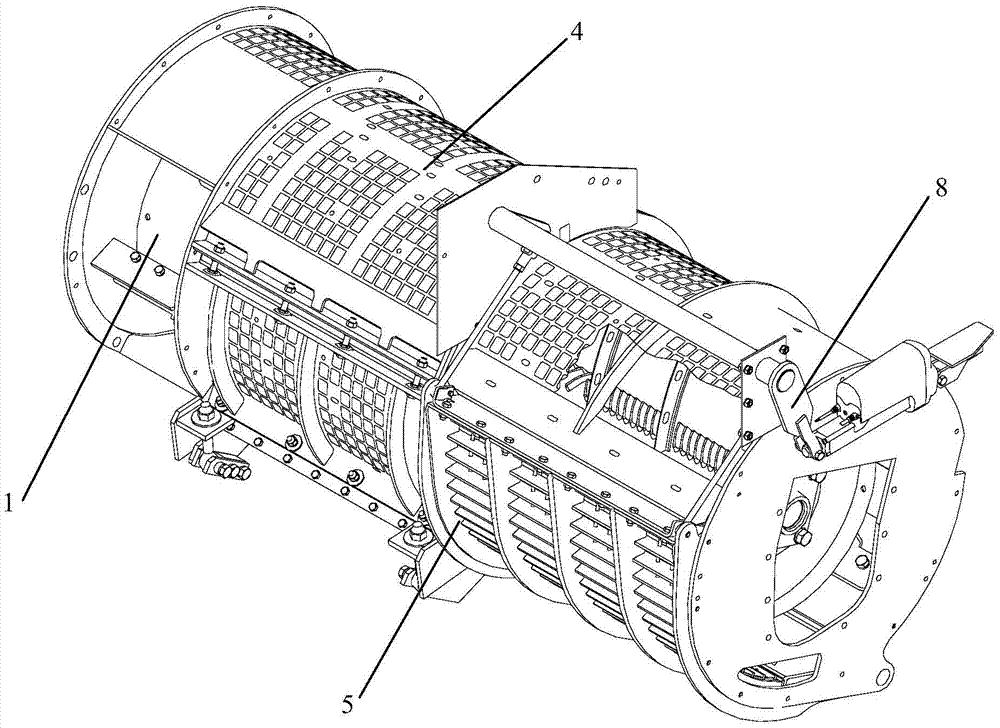

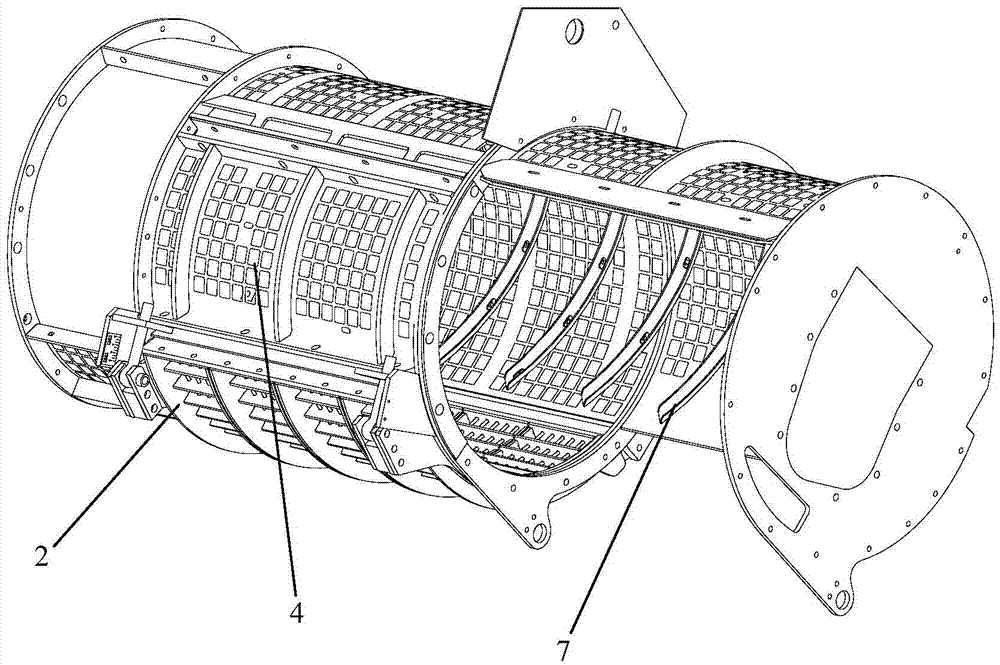

Transverse axial flow threshing and separating device

A technology of threshing separation and horizontal axial flow, which is applied in threshing equipment, applications, agricultural machinery and implements, etc., can solve the problems of low efficiency and small feeding amount, and achieve the advantages of reduced crushing rate, low power consumption and stable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

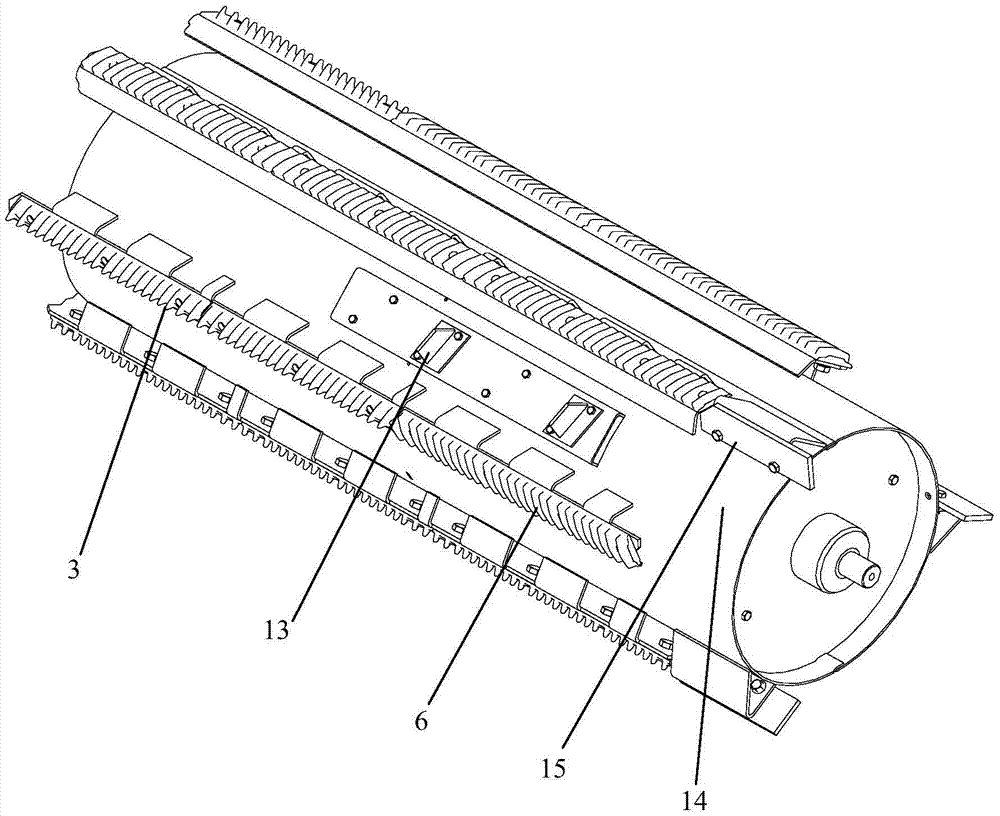

[0036] The entire separating area can be equipped with reverse graining rod 6 as required, which is coaxially arranged on the drum main body 14 with forward graining rod 3, so as to achieve better threshing effect and greatly reduce the phenomenon of grain breaking and shell breaking. All the other are the same as embodiment one.

Embodiment 3

[0038] The threshing drum 1 is a closed structure. All the other are the same as embodiment one.

Embodiment 4

[0040] The forward grained stem 3 or the reversed grained stem 6 is a deep grained stem, so as to generate enough pressure to allow the grains to separate, and at the same time reduce the impact of the green stalk material between the grained stem and the shell, and reduce the breakage rate. All the other are the same as embodiment one.

[0041] The working process of the horizontal axial flow threshing and separation device:

[0042] The grain enters the drum feed port 10 from the constant angle feed system 9 at the front end at a smoother, uniform, continuous speed and constant direction, starting the threshing and separation process. With the cooperation of the adjustable concave plate 5 in the threshing section, more than 85% of the threshing can be achieved and a part of the fallen grains can be separated. The chrome-plated high-position positive groove bar 3 can generate enough pressure to let the grains break away, and at the same time Reduce the impact of green stalk ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com