Rigid-flex PCB with flexible region equipped with solder pad and manufacturing method thereof

A technology of rigid-flex board and flexible area, applied in the field of rigid-flex board, can solve the problems of time-consuming and laborious, low overall efficiency, and many consumables, so as to reduce production costs, reduce the number of immersion gold, and simplify the process flow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

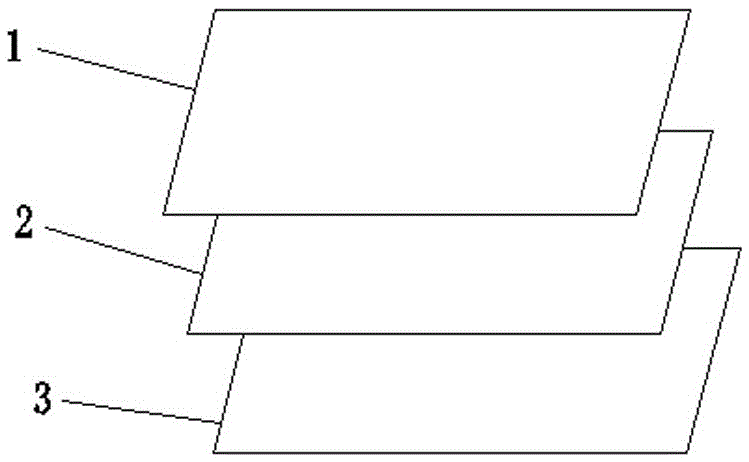

[0030] like figure 1 As shown, a rigid-flex board with a pad in the flexible area includes a flexible board 1, a cover film, a PP prepreg 2, and a rigid board 3. The middle of the flexible board 1 is provided with a pad, with a solder pad. The outer surface of the flexible plate 1 of the disk is covered with a cover film, and the cover film is provided with a window suitable for the pad, and the window is compensated by increasing 0.1mm on one side. The flexible board 1 combined with the covering film, the PP prepreg 2 and the rigid board 3 are sequentially arranged and pressed from top to bottom to form a rigid-flex board.

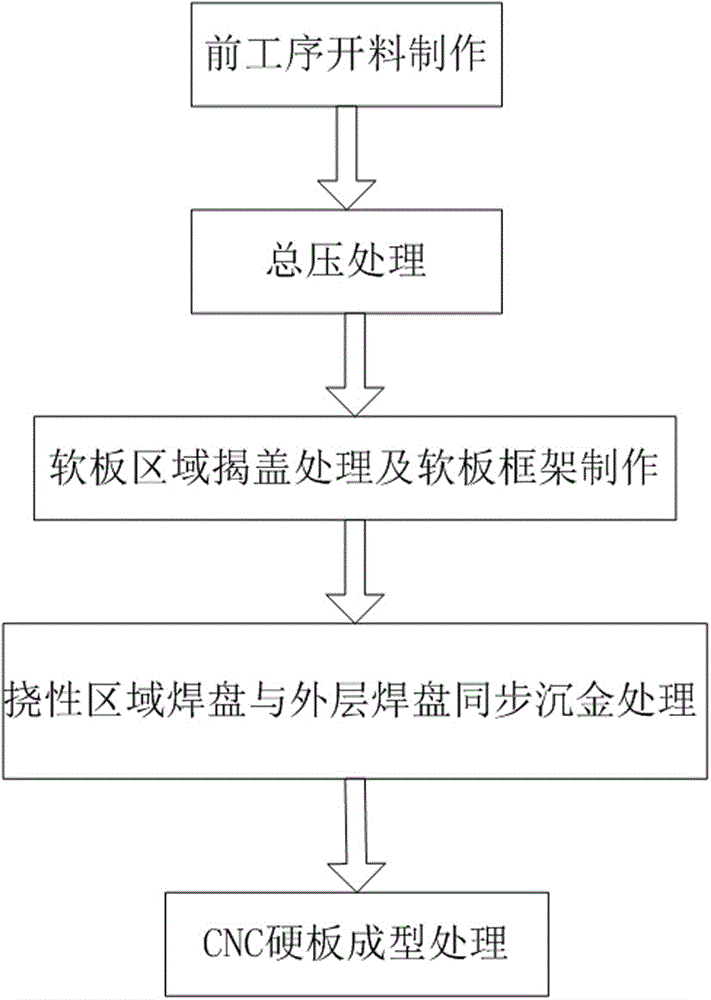

[0031] like figure 1 and figure 2 As shown, a method for manufacturing a rigid-flex board with a pad in a flexible region includes the following steps:

[0032] The first step is the production of various raw materials in the previous process. The flexible board 1 with copper pads is manufactured until the cover film is pressed quickly, and the cover ...

Embodiment 2

[0044] like figure 1 As shown, a rigid-flex board with a pad in the flexible area includes a flexible board 1, a cover film, a PP prepreg 2, and a rigid board 3. The middle of the flexible board 1 is provided with a pad, with a solder pad. The outer surface of the flexible plate 1 of the disk is covered with a cover film, and the cover film is provided with a window suitable for the pad, and the window is compensated by increasing 0.2mm on one side. The flexible board 1 combined with the covering film, the PP prepreg 2 and the rigid board 3 are sequentially arranged and pressed from top to bottom to form a rigid-flex board.

[0045] like figure 1 and figure 2 As shown, a method for manufacturing a rigid-flex board with a pad in a flexible region includes the following steps:

[0046] The first step is the production of various raw materials in the previous process. The flexible board 1 with copper pads is manufactured until the cover film is pressed quickly, and the cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com