Curing process for negative plate of lead acid battery

A lead-acid battery and curing process technology, applied in the direction of lead-acid battery electrodes, etc., can solve the problems of long curing and drying cycle, slow oxygen entry and transmission, active material shedding, etc., to achieve shortened curing process time, uniform and effective heat loss, and various Item indicators are stable and consistent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] 1. A curing process for improving the quality of battery negative plates, comprising the following steps:

[0062] (1) Hang the raw plate vertically, and keep the distance between the two raw plates above 5mm;

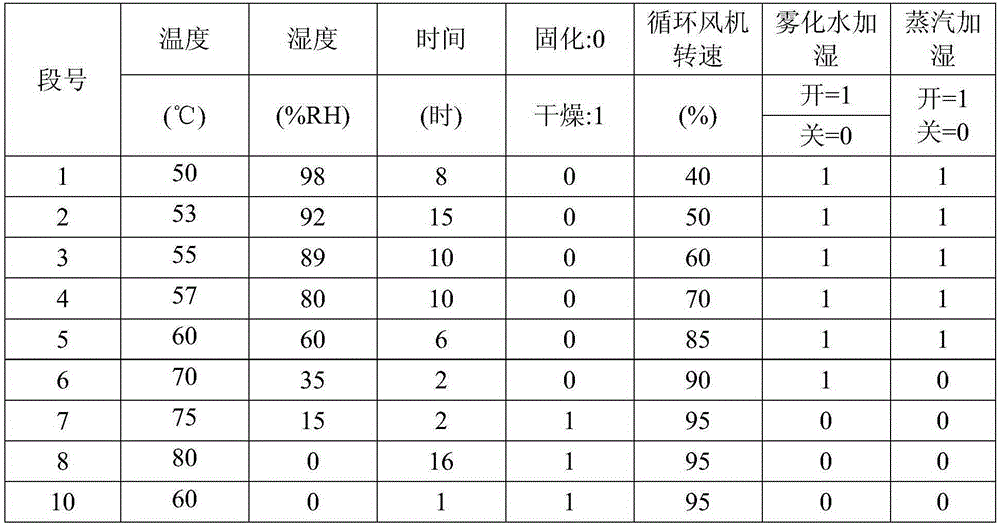

[0063] (2) Curing and drying, the parameters of each stage are shown in Table 4.

[0064] Table 4

[0065]

[0066] Note: Adjust the humidity by spraying atomized water into the curing room, and add a direct steam injection device to ensure that the humidity is adjusted when the temperature rises; spray air into the curing room to ensure the oxygen supply in the room. In the eighth stage in Table 4, the drying process starts, and the speed of the circulating fan reaches the maximum to accelerate the dehumidification.

[0067] The entire curing process of this embodiment takes 48 hours, which is 22 hours shorter than the 70 hours of Comparative Example 1, which greatly improves the turnover rate of the curing chamber and improves production efficiency.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com