Automatic terminal insertion hinge device

A terminal and equipment technology, applied in the field of automatic manufacturing of miniature electronic components, can solve the problems of large floor space and energy consumption, large processing error, low product qualification rate, etc. efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

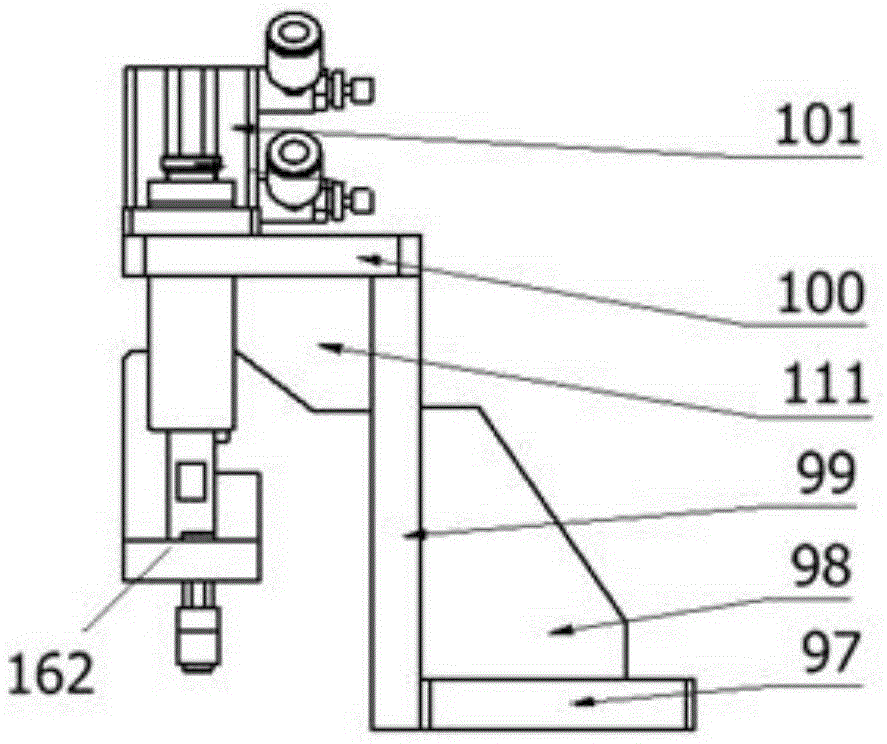

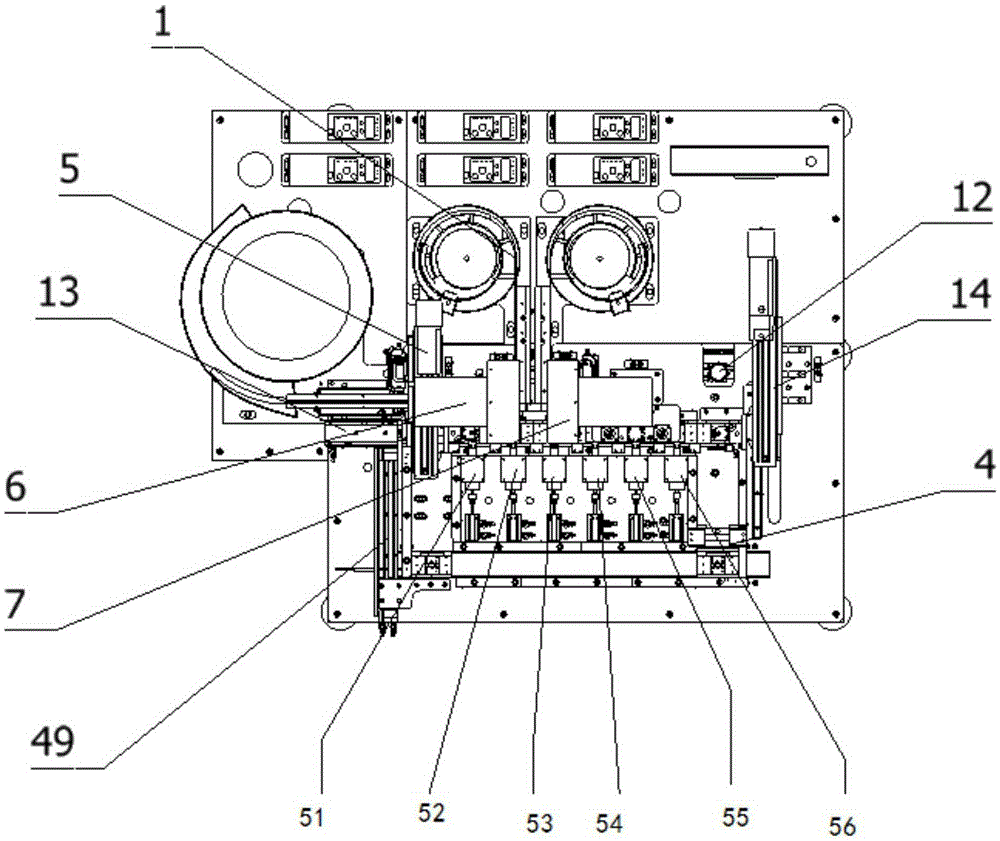

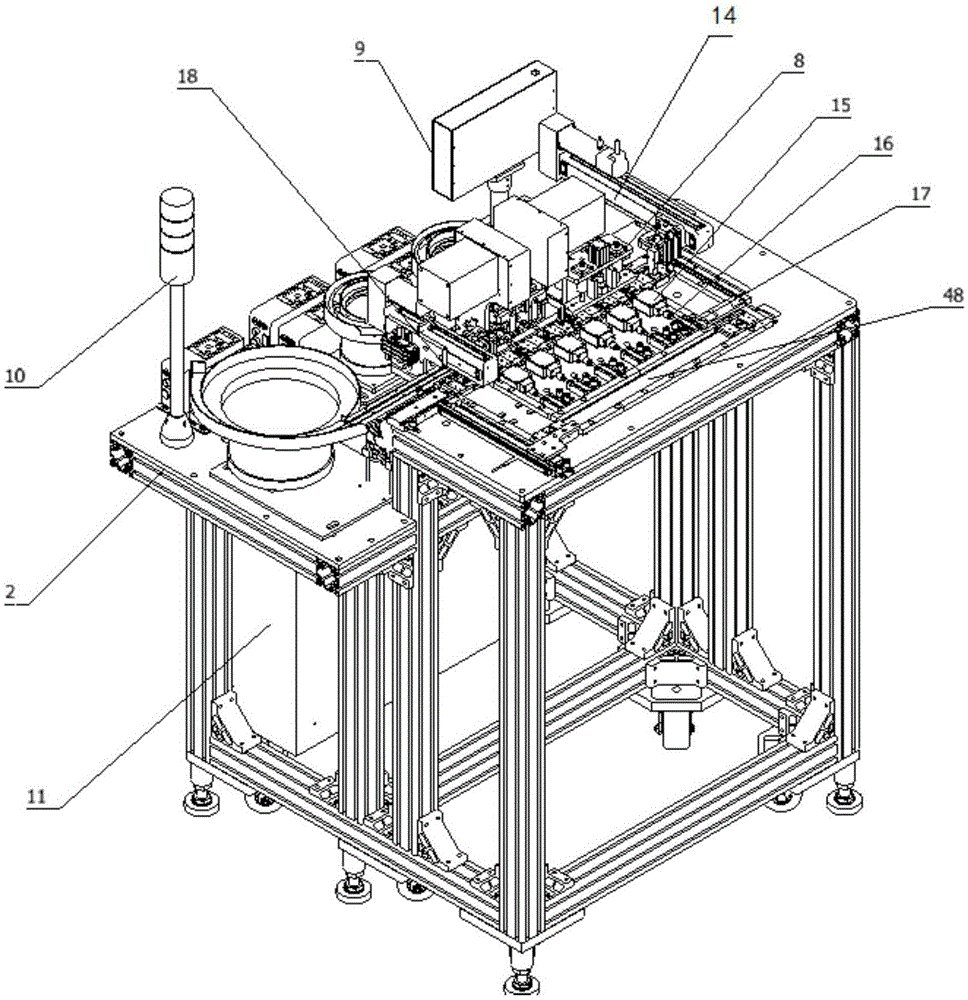

[0027] like figure 1 and 2 , an automatic terminal insertion and hinged equipment includes a workbench and a circular transport system 4 fixed on the workbench, six stations arranged on the circular conveyance system 4, station positioning and pressing on each station Mechanism 16, the workpiece transport mechanism 5 for transporting the workpiece to the first station 51, the left terminal insertion mechanism for inserting the terminal at the left end of the workpiece at the second station 52, and the left terminal insertion mechanism for The terminal is inserted into the right terminal insertion mechanism at the right end of the workpiece at 53, a hinge mechanism 36 above the fourth to sixth stations, a lifting mechanism 37 for lifting the hinge mechanism 36, a hinge mechanism 36 located A workpiece pressing mechanism 8 that is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com