Chemical process fault monitoring method based on active learning

A chemical process and fault monitoring technology, applied in program control, electrical test/monitoring, test/monitoring control systems, etc., can solve problems such as difficult to collect fault type data and limit the application of naive Bayesian classifiers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

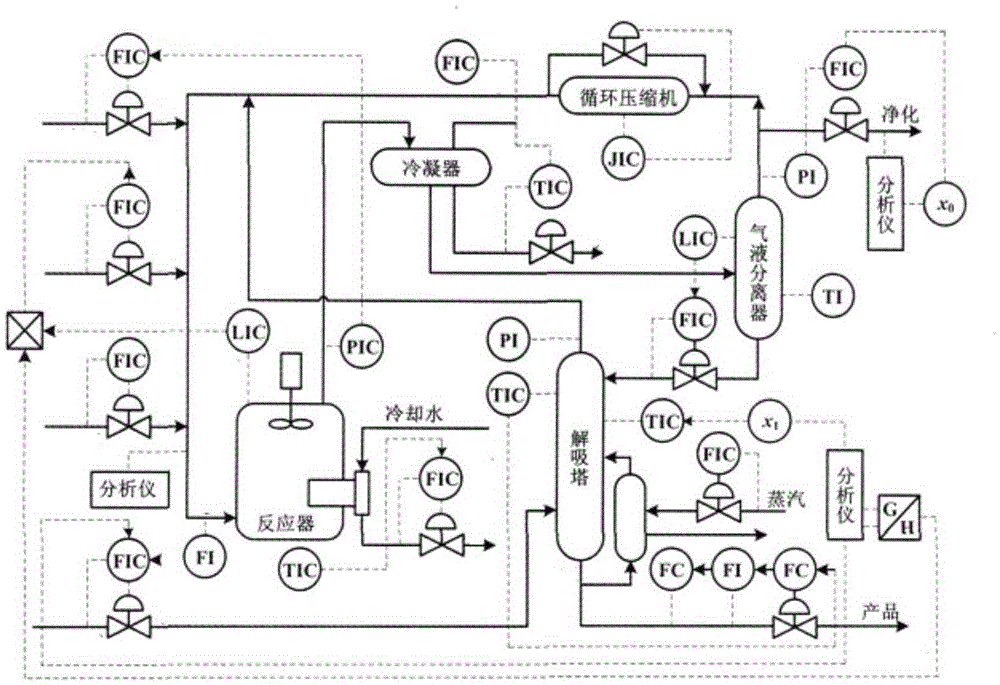

[0049] Such as figure 1 As shown, the chemical process fault monitoring method based on active learning of the present embodiment is applied in the TennesseeEastmanProcess (TEP) process; the TEP industrial process is created by Eastman Chemical Company of the United States, and this industrial process has four reactants (A, C , D, E), produce two products (G and H), wherein, material A is H 2 Hydrogen, material B is N 2 Ammonia, material C is CO carbon monoxide, material D is CH 3 OH methanol, material E is C 2 h 5 OH ethanol, product G is C 2 h 6 o 2 Ethylene glycol, product H is C 3 h 8 o 2 Propylene glycol; the whole process includes five main reaction devices: reactor, condenser, cycle compressor, desorption tower and gas-liquid separator, with a total of 50 variables and 16 failure types.

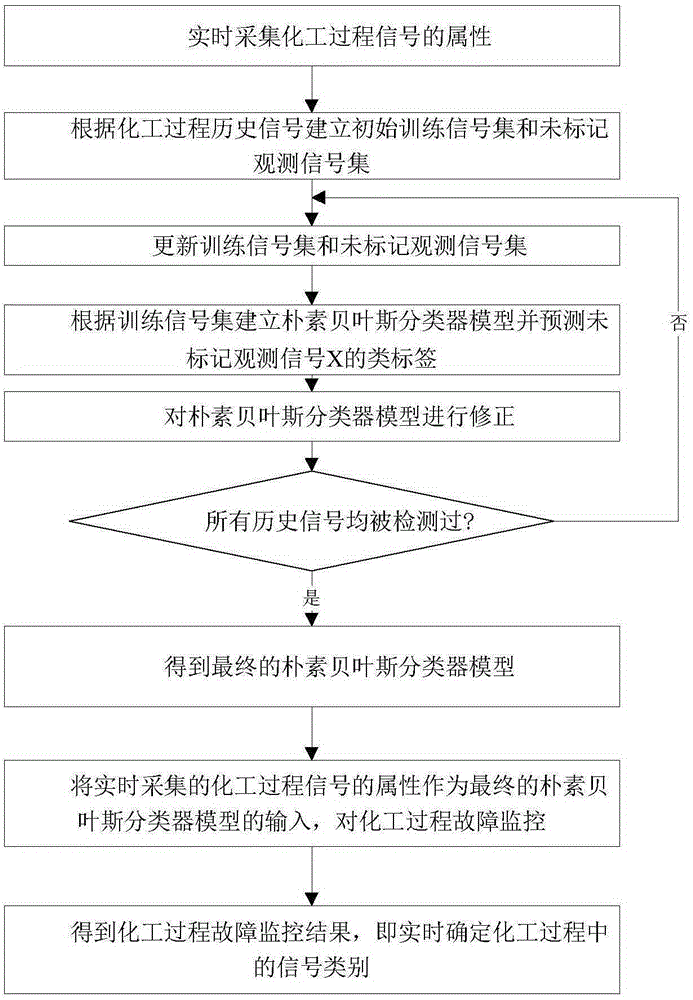

[0050] A chemical proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com