Polymer material density testing equipment

A technology of polymer materials and testing equipment, applied in the direction of analyzing materials, measuring devices, specific gravity measurement, etc., can solve the problems of inability to test polymer materials, achieve the effect of convenient disassembly and vacuum extraction, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

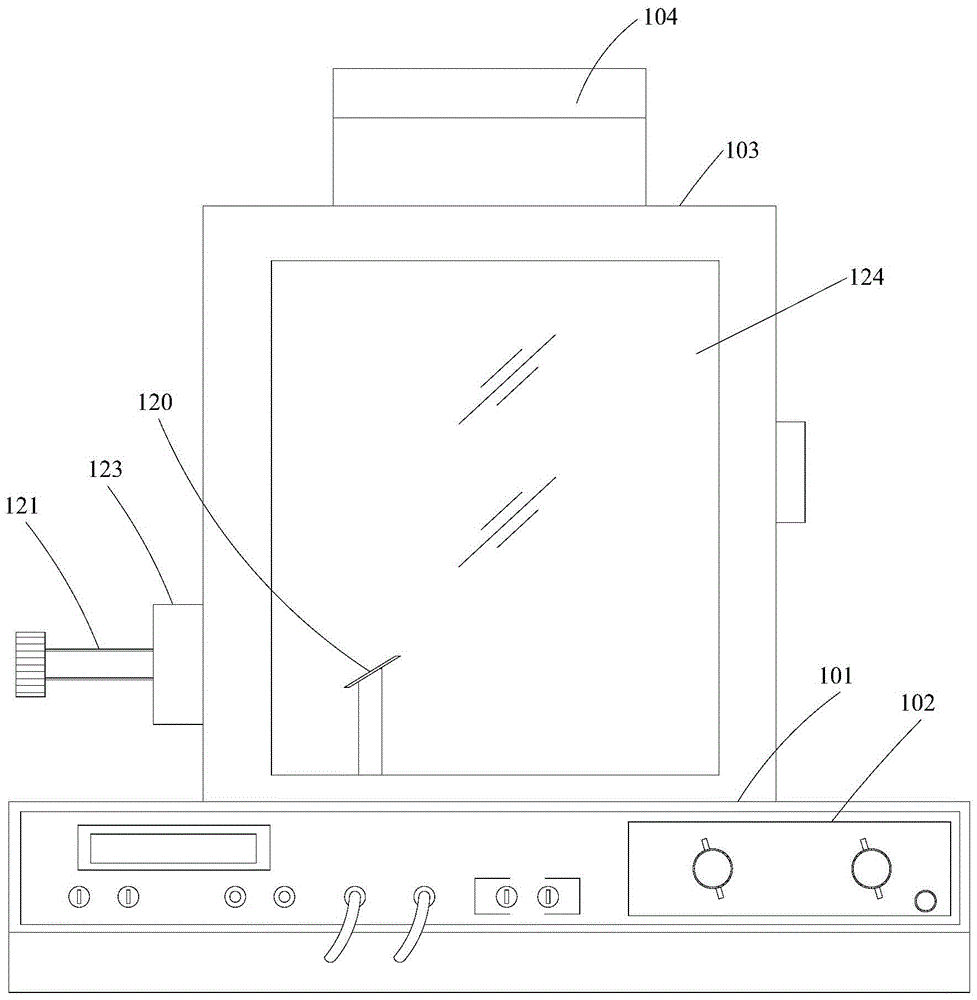

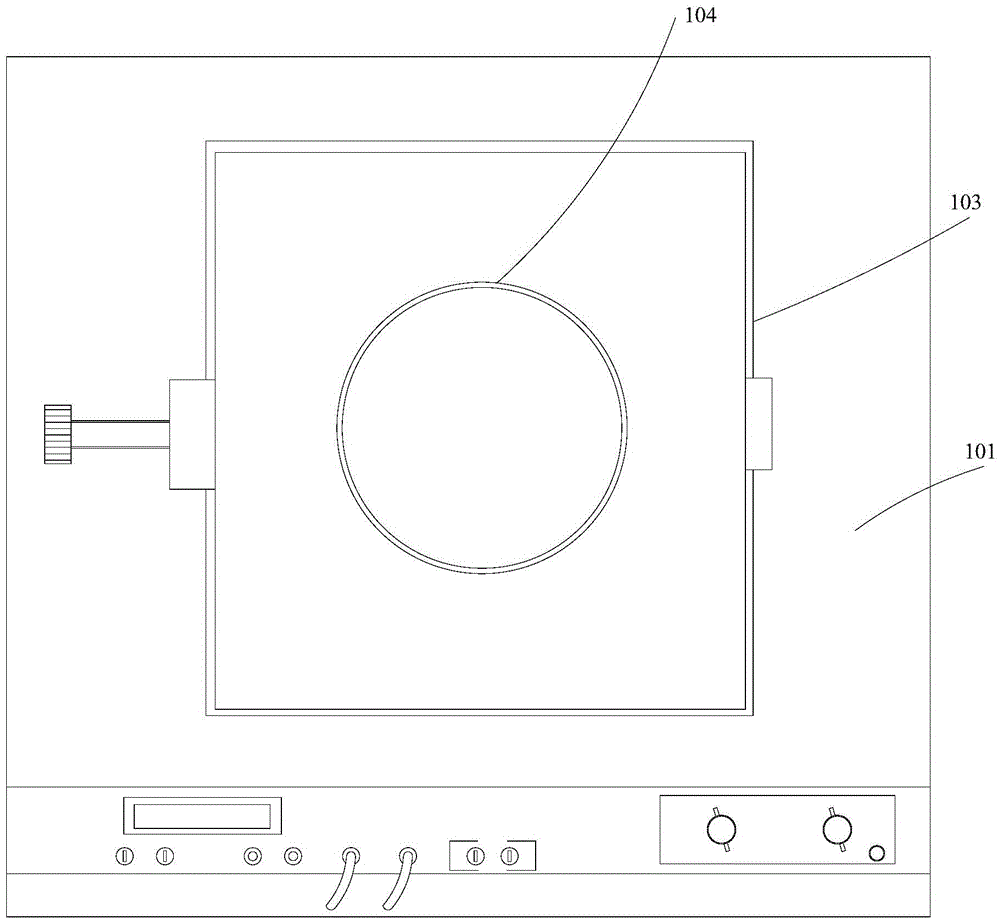

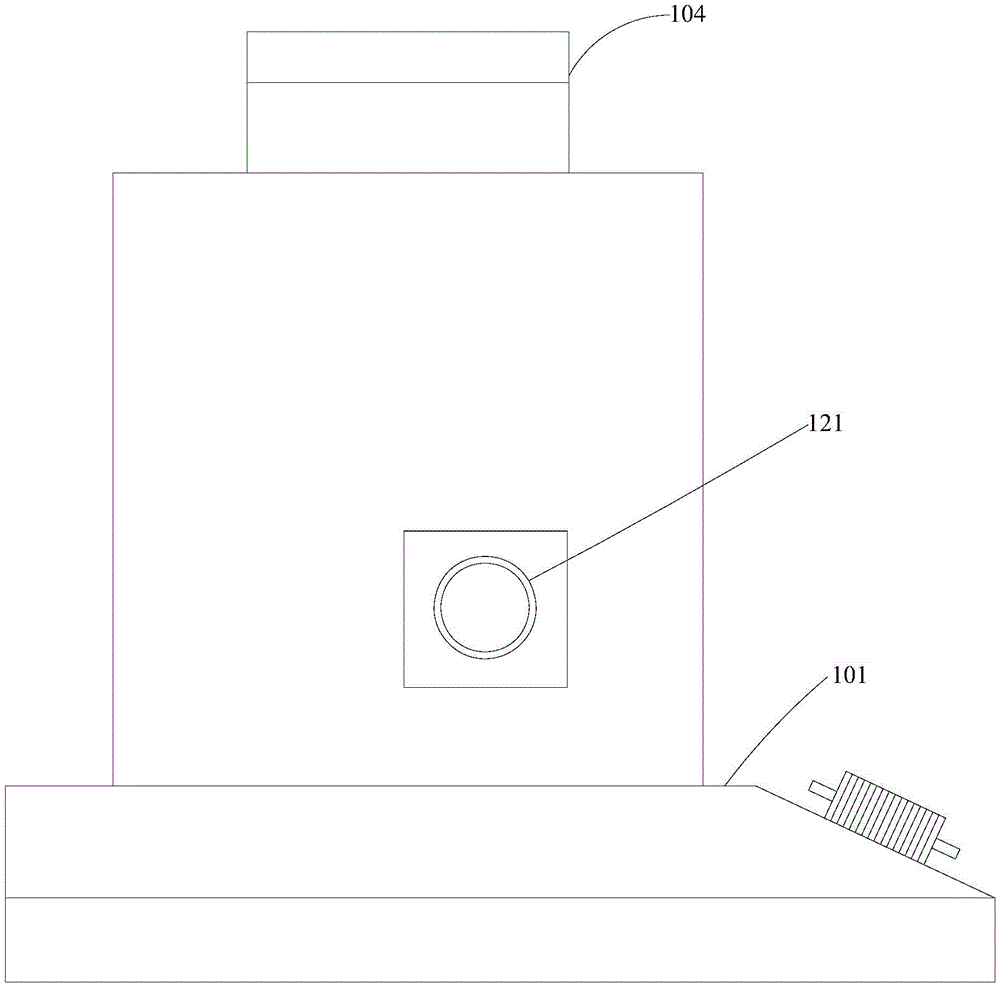

[0058] A kind of macromolecule material density testing equipment, comprises equipment body 101, and this equipment body 101 comprises weight tester 102, and the top of equipment body 101 is provided with the vacuum cover 103 that is detachably connected with it, and the top of this vacuum cover 103 is provided with its screw connection. The cover 104, the side wall of the vacuum cover 103 is provided with an air suction port 105; the top of the device body 101 is provided with a plug-in mechanism 106, and the plug-in mechanism 106 includes a slot 107, and the outer side of the slot 107 is provided with an annular first Boss 108, the top of first boss 108 is provided with sealing ring 109; The outer bottom of vacuum cover 103 is provided with annular second boss 110, and the height of this second boss 110 is lower than first boss 108, and There is a gap between the first boss 108 and the second boss 110 ; the edge of the sealing ring 109 extends out of the first boss 108 and ex...

Embodiment 2

[0060] A kind of macromolecule material density testing equipment, comprises equipment body 101, and this equipment body 101 comprises weight tester 102, and the top of equipment body 101 is provided with the vacuum cover 103 that is detachably connected with it, and the top of this vacuum cover 103 is provided with its screw connection. The cover 104, the side wall of the vacuum cover 103 is provided with an air suction port 105; the top of the device body 101 is provided with a plug-in mechanism 106, and the plug-in mechanism 106 includes a slot 107, and the outer side of the slot 107 is provided with an annular first Boss 108, the top of first boss 108 is provided with sealing ring 109; The outer bottom of vacuum cover 103 is provided with annular second boss 110, and the height of this second boss 110 is lower than first boss 108, and There is a gap between the first boss 108 and the second boss 110 ; the edge of the sealing ring 109 extends out of the first boss 108 and ex...

Embodiment 3

[0063] A kind of macromolecule material density testing equipment, comprises equipment body 101, and this equipment body 101 comprises weight tester 102, and the top of equipment body 101 is provided with the vacuum cover 103 that is detachably connected with it, and the top of this vacuum cover 103 is provided with its screw connection. The cover 104, the side wall of the vacuum cover 103 is provided with an air suction port 105; the top of the device body 101 is provided with a plug-in mechanism 106, and the plug-in mechanism 106 includes a slot 107, and the outer side of the slot 107 is provided with an annular first Boss 108, the top of first boss 108 is provided with sealing ring 109; The outer bottom of vacuum cover 103 is provided with annular second boss 110, and the height of this second boss 110 is lower than first boss 108, and There is a gap between the first boss 108 and the second boss 110 ; the edge of the sealing ring 109 extends out of the first boss 108 and ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com