Furniture static pressure fatigue test machine

A fatigue test, static pressure technology, applied in impact test, test of machine/structural components, test of material strength by applying repetitive force/pulse force, etc. Height adjustment and other issues, to achieve the effect of convenient positioning, stable and reliable loading force value, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

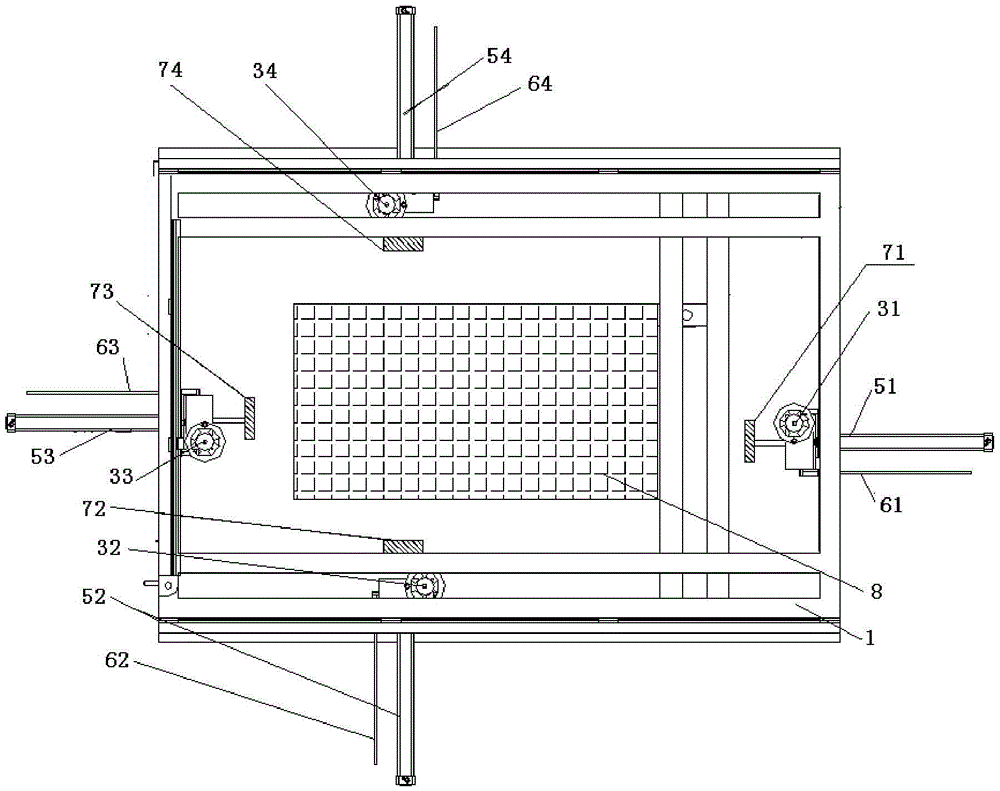

[0040] like Figure 1~2As shown, the present invention provides a specific embodiment of a furniture static pressure fatigue testing machine, including a frame 1 and a central controller, and the top of the frame 1 is fixedly installed with a transverse motor 11, a transverse lead screw 12, a longitudinal motor 21 and Vertical lead screw 22, vertical lead screw 12 and vertical lead screw 22 are mutually vertically arranged; Wherein: horizontal motor 11 is connected with horizontal lead screw 12, and horizontal lead screw 12 is provided with transverse track 13; The rods 22 are connected, and a longitudinal track is provided under the longitudinal lead screw 22; the longitudinal track includes a first longitudinal track 23-1 and a second longitudinal track 23-2, and the top of the first impact cylinder 14 is installed on the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com