Nozzle structure, and air sterilizer and humidifier including same

A nozzle and punching bag technology, which is applied in air humidification system, disinfection, lighting and heating equipment, etc., can solve the problems affecting the service life of devices, pollution, affecting the effect of air purification, disinfection and humidification, etc., so as to avoid pollution and increase the service life , improve the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

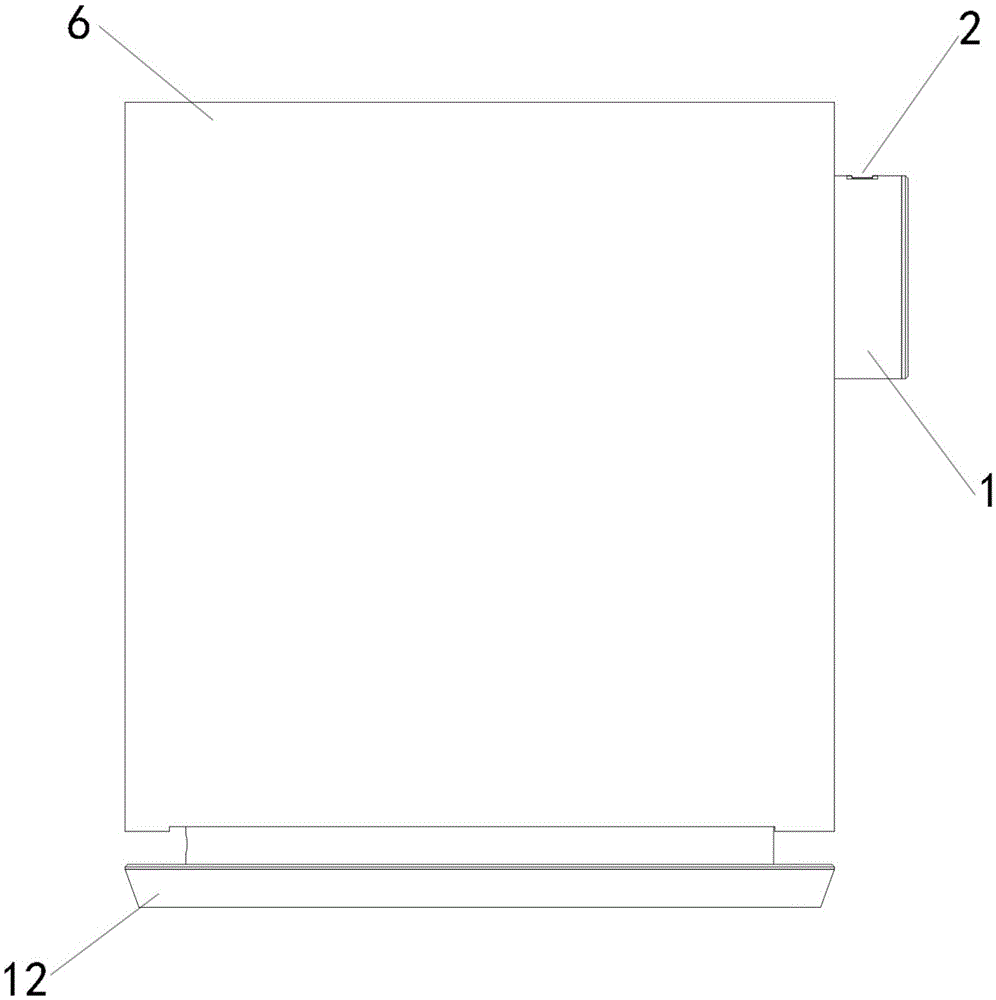

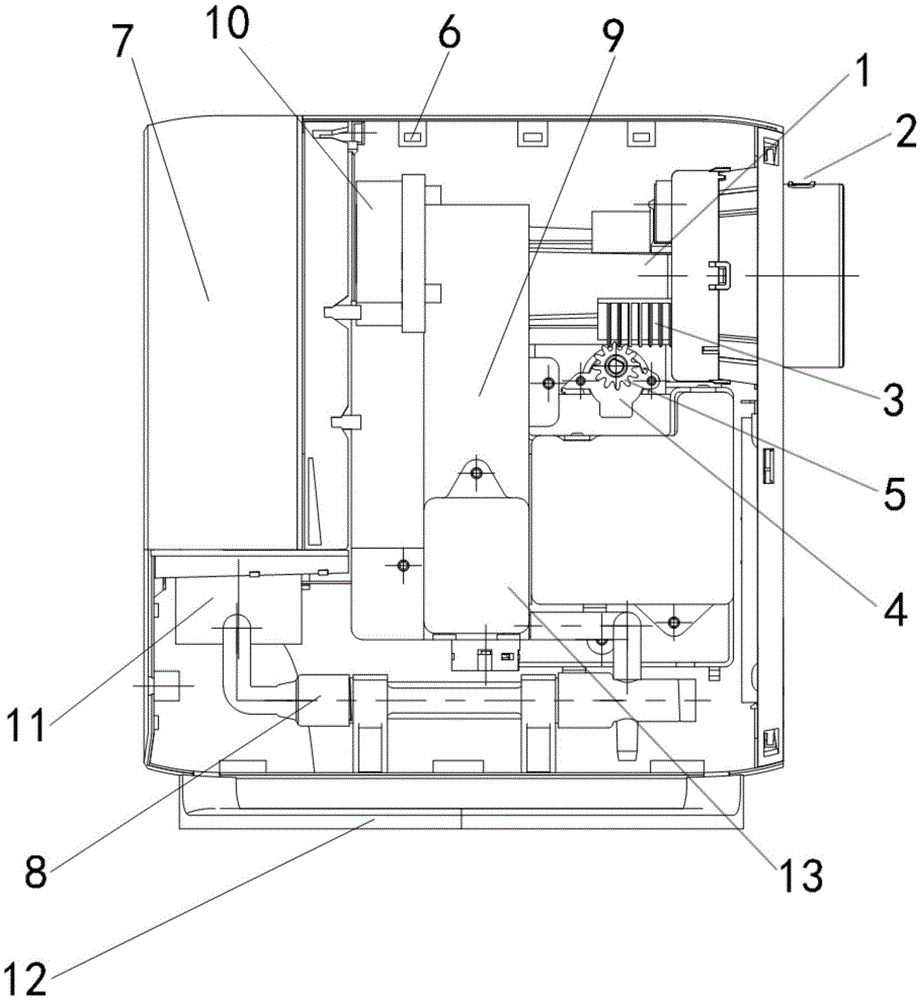

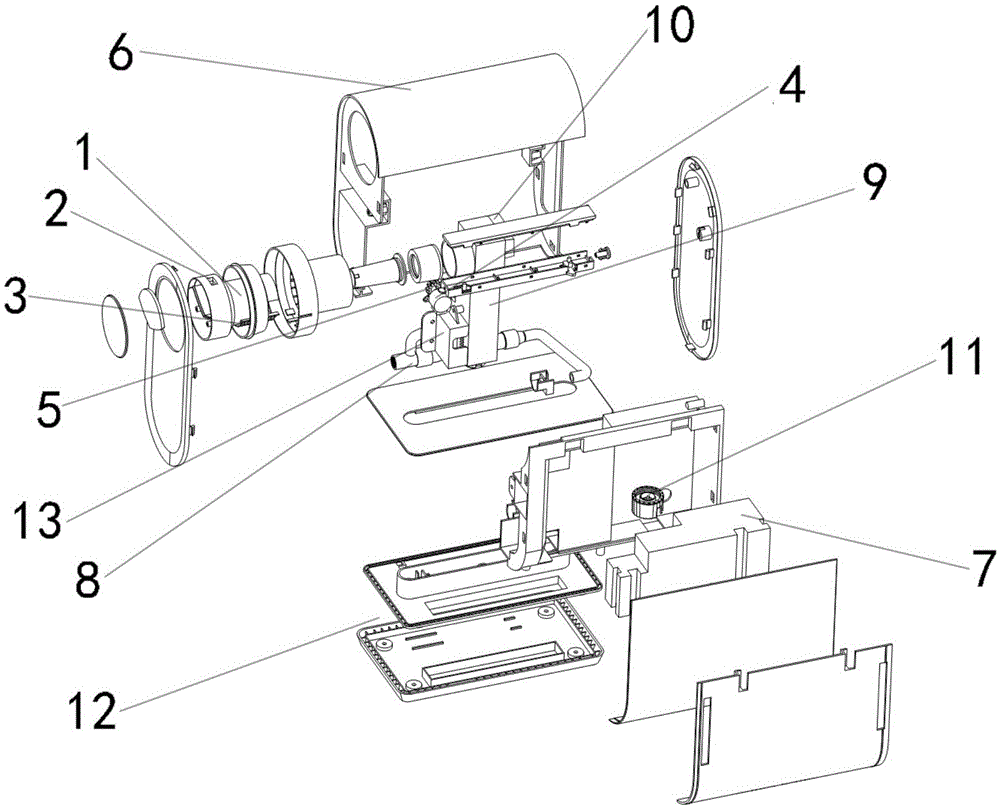

[0027] Such as figure 1 , figure 2 and image 3 As shown, the present invention relates to a nozzle structure, comprising a punching bag 1 and a nozzle 2 arranged at one end of the punching bag 1, the nozzle 2 is arranged on the circumferential side wall of one end of the punching bag 1, and the nozzle structure also includes a nozzle capable of driving the punching bag. 1 The nozzle propulsion mechanism that moves back and forth. In the present invention, the punching bag 1 is designed to be movable. When in use, the nozzle 2 extends out of the casing 6, and the air flow is ejected to purify, disinfect and humidify the air. When not in use, the nozzle 2 is retracted into the casing 6 to protect the nozzle 2 and prevent create pollution. Compared with the fixed nozzle 2 in the prior art, the structure of the present invention can be that the nozzle 2 is retracted into the casing 6 when not in use, and other pollutants in the room are isolated from the casing 6, and will no...

Embodiment 2

[0036] Such as Figure 1 to Figure 3 As shown, the present invention relates to an air sterilizer, comprising a housing 6 and a water tank 7 arranged in the housing 6, an electrolytic tube 8 and an atomizer 9, and also includes the nozzle structure, the water tank 7, the electrolytic tube 8 , the atomizer 9 and the outlet cylinder 1 in the nozzle structure are connected in sequence, and the nozzle propulsion mechanism can drive the outlet cylinder 1 to move back and forth, so that the nozzle 2 extends out of the casing 6 or retracts into the casing 6 Inside.

Embodiment 3

[0038] The present invention relates to a humidifier, which includes a casing 6, a water tank 7 and an atomizer 9 arranged in the casing 6, and also includes the spray head structure, the water tank 7, the atomizer 9 and the spray head structure The punching tubes 1 are connected sequentially, and the spray head propulsion mechanism can drive the punching tube 1 to move back and forth, so that the spray head 2 protrudes out of the casing 6 or retracts into the casing 6 .

[0039] In the above-mentioned air sterilizer and humidifier, a blower fan 10 is provided on the side of the atomizer 9 relative to the outlet tube 1, a base 12 for supporting is also provided at the bottom of the housing 6, and the side wall of the atomizer 9 is provided with a Control the circuit control board 13 of humidifier operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com