Grouting reinforcement treatment method for mid-depth goaf below building foundation

A technology of grouting reinforcement and goaf, which is applied in the direction of mining equipment, earthwork drilling, filling, etc. It can solve problems such as deformation damage, reduction of mine pillar strength, and house collapse, so as to improve the overall stability and anti-deformation ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Data collection and investigation: data collection of mine hydrogeological data, resource occurrence conditions, mining design, mining methods, mining technology, and goaf treatment methods; on-site investigation of underground mining conditions and surface subsidence measurement data.

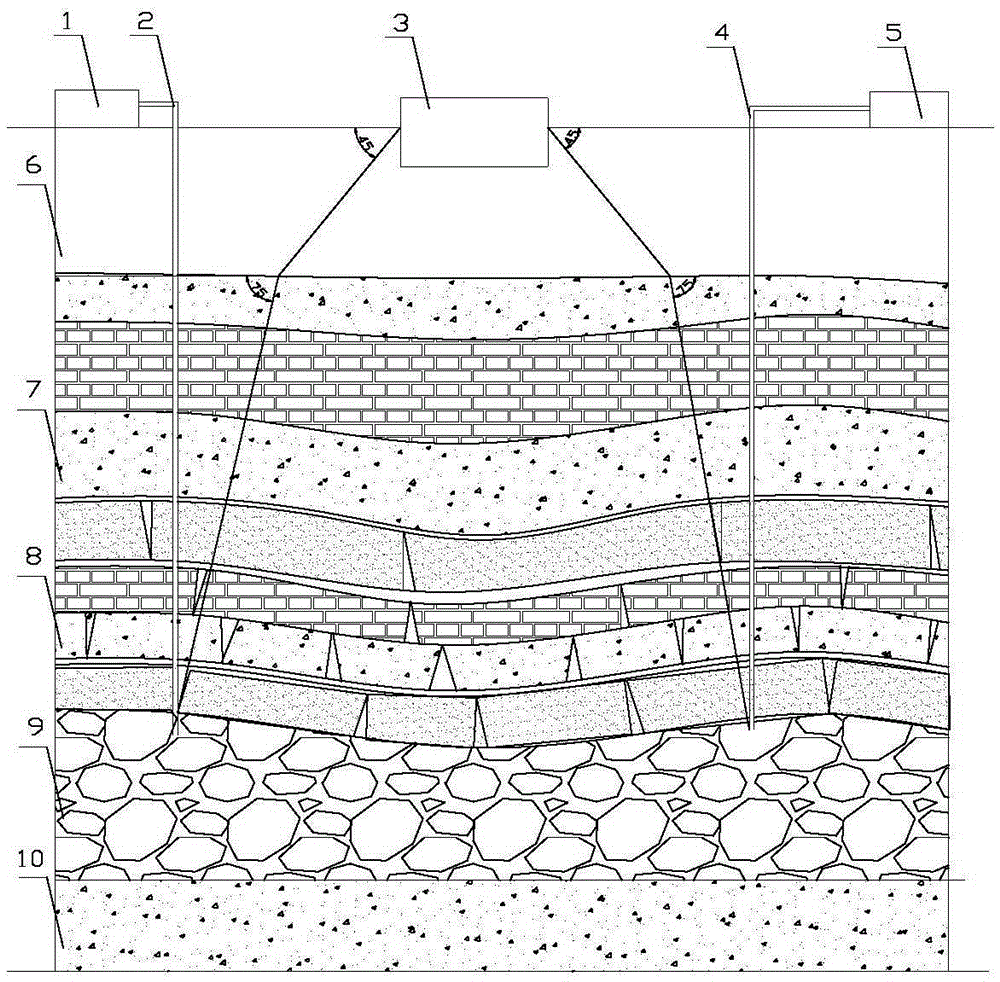

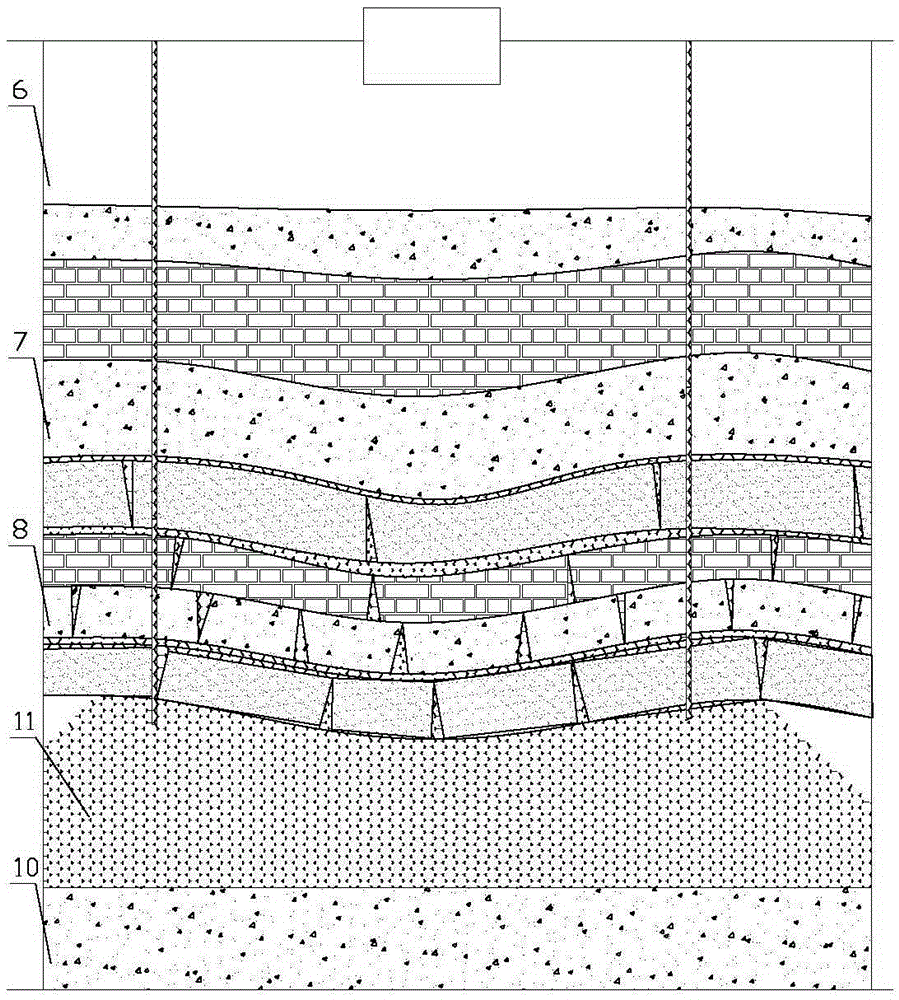

[0029] Reinforcement scheme: The foundation reinforcement treatment of the goaf is less than 30m, and methods such as dynamic compaction, excavation and backfill, pile foundation, grouting, grid plate, etc. can be used; the foundation reinforcement treatment of the goaf is greater than 30m by grouting filling.

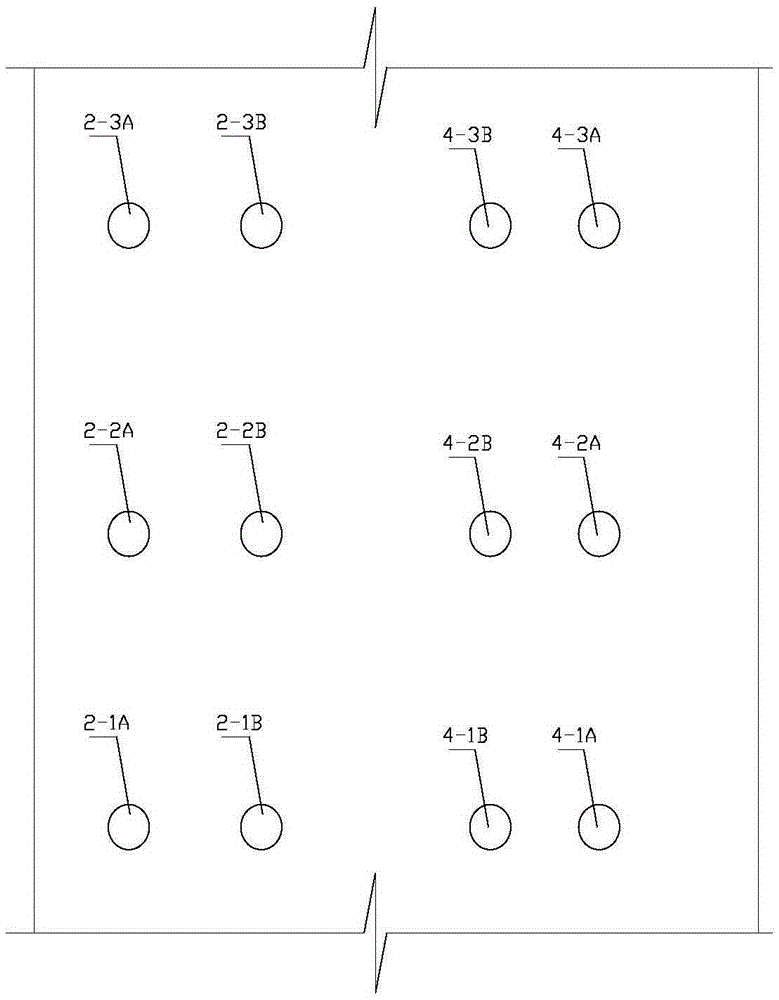

[0030] Determination of the grouting range: According to the investigation and collected data, determine the grouting drainage holes (2-1A, 2-2A, 2-3A, 4-1A, 4-2A, 4-3A) and the foundation (3) through theoretical calculations The horizontal distance between the outer sides and the grouting depth, and the preliminary reinforcement range; when the data collected and investigated ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com