Large-scale wading ring-shaped rigid foundation and construction method thereof

A rigid foundation and annular technology, applied in the field of large-scale water wading annular rigid foundation and its construction, can solve the problems of poor economy, large amount of engineering, poor economy, etc., and achieve the effect of saving materials and good economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings.

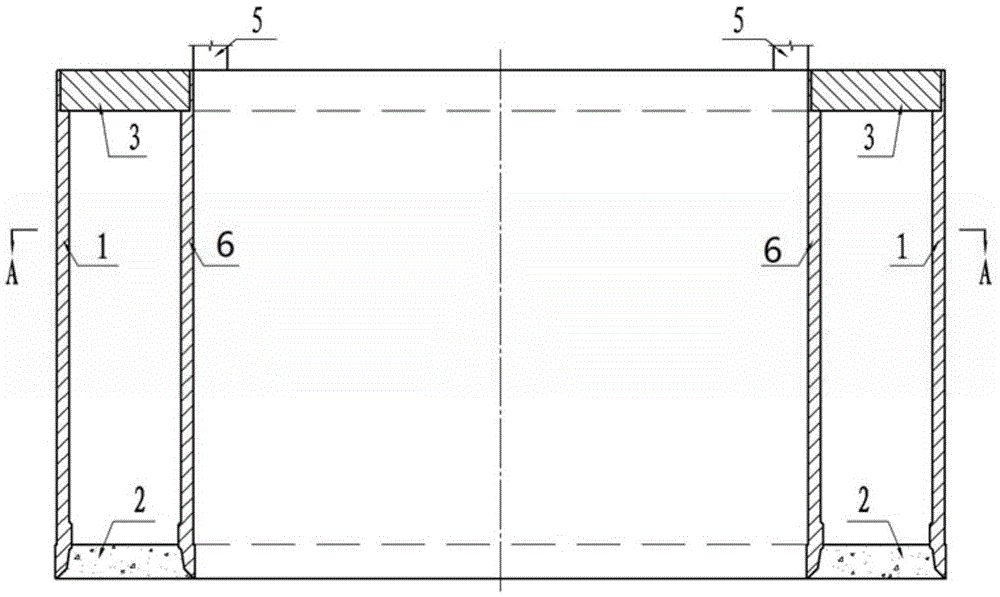

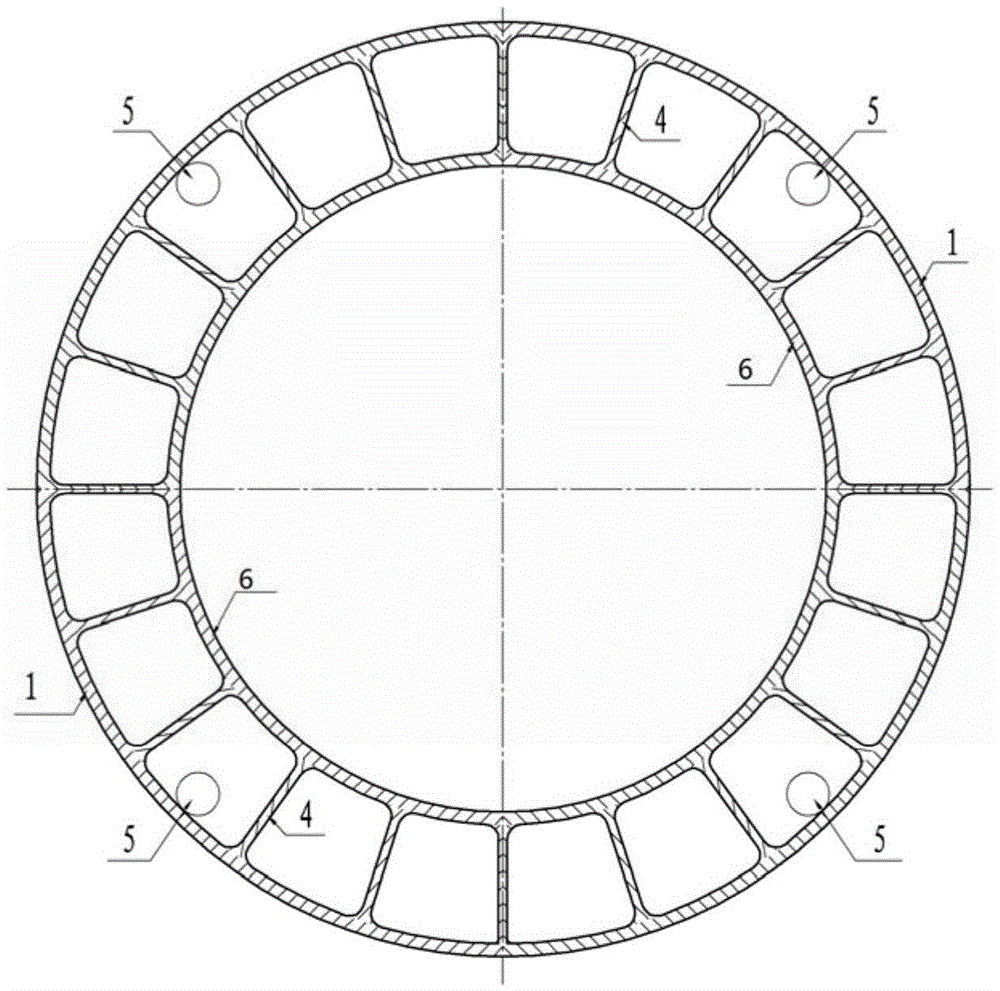

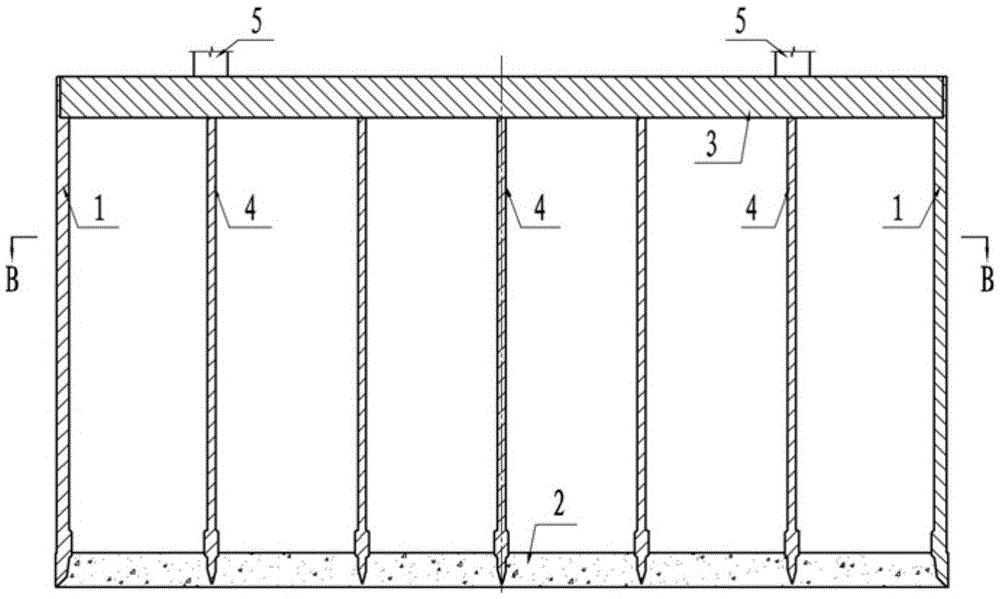

[0014] refer to figure 1 , figure 2 , there is an inner well wall 6 within 20-25m of the outer well wall 1 of the large-scale wading annular rigid foundation, and the inner and outer well walls are sealed with a ring cover plate 3 on the top and a ring bottom sealing concrete 2 on the bottom to form a closed ring body , there is a partition wall 4 in the middle of the inner and outer well walls.

[0015] The inner and outer shaft walls at the bottom section and the middle partition wall 4 are made of steel shell concrete with a vertical height of 45m; the inner and outer shaft walls and the middle partition wall at the rest are made of reinforced concrete with a vertical height of 29.5m.

[0016] The total height of the large-scale wading ring-shaped rigid foundation is 74.5m, the thickness of the inner and outer well walls is 1.8m according to the actual water a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com