Cement flour sprinkling machine

A technology of spreading machine and cement powder, which is applied to roads, road repairs, roads, etc. It can solve the problems of increasing road construction costs, unsatisfactory construction effects, and low work efficiency, so as to meet the construction quality and progress and facilitate disassembly. , work efficiency and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

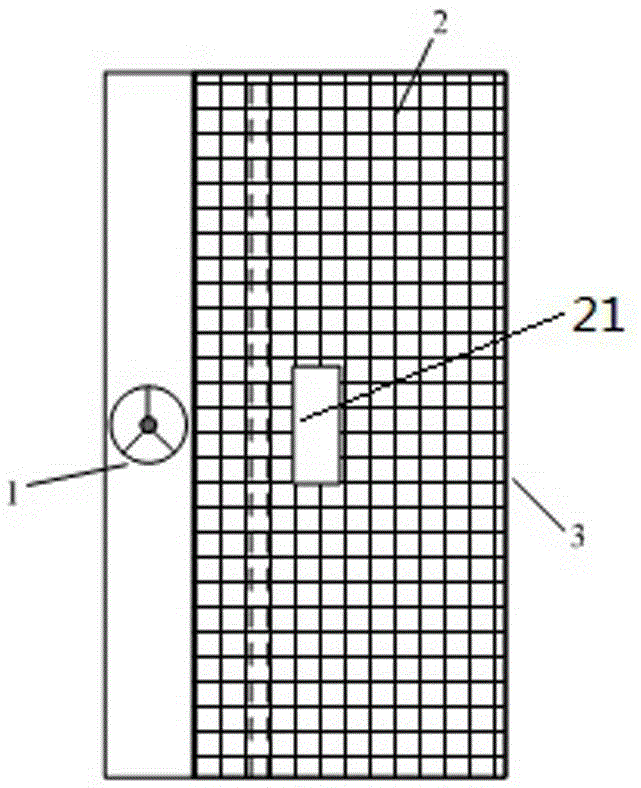

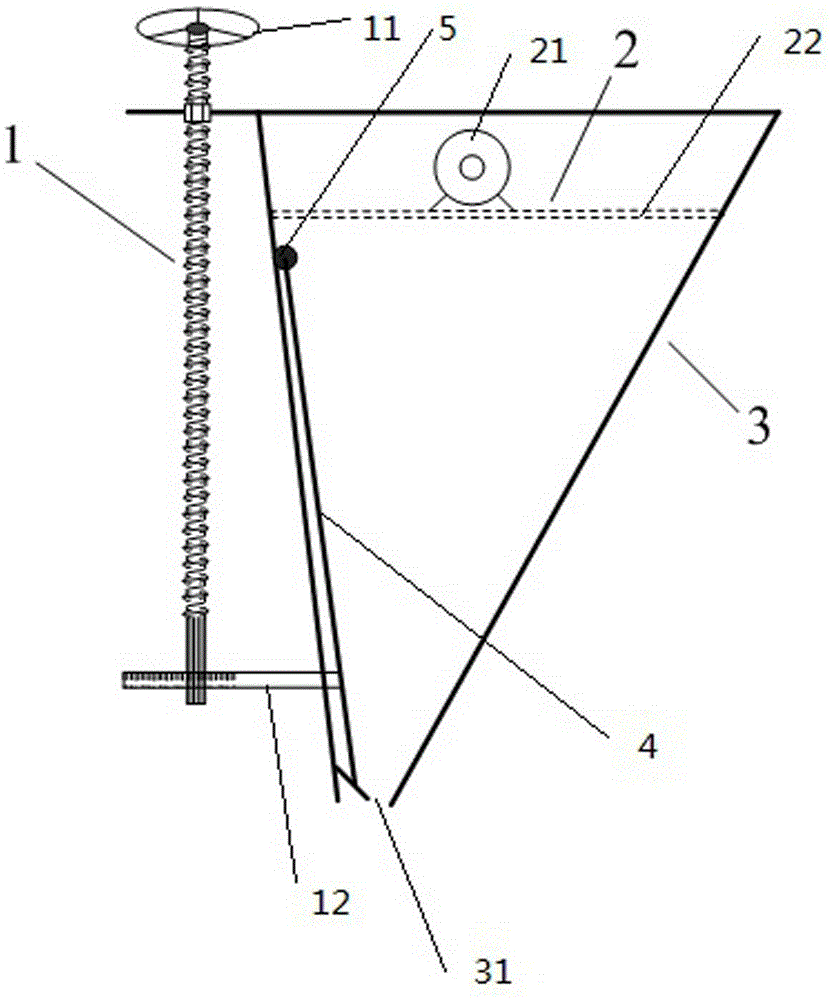

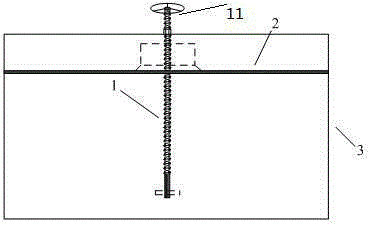

[0015] Such as figure 1 , 2 Shown in and 3, a kind of cement powder spreading machine of the present invention comprises hopper 3, is provided with vibrating screen 2 on the top of hopper 3, is also provided with the baffle plate 4 that swings freely around certain axis 5 in hopper 3, The different swing angles of the baffle plate 4 control the different sizes of the discharge port 31; the outside of the hopper 3 is provided with a screw transmission mechanism 1, the upper end of the screw transmission mechanism 1 is a rotary handle 11, and the lower end is a connecting rod 12, the connecting rod 12 The other end of the rod 12 is in contact with the baffle 4 . The above-mentioned vibrating mesh screen 2 includes two parts: a miniature vibrating motor 21 and an iron mesh screen 22 . The miniature vibrating motor 21 is fixed on the middle part of the iron mesh screen 22 by welding. The sectional view of the hopper 3 in this embodiment is triangular.

[0016] When the concret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com