Double-thread-loosening mechanism for sewing machine and sewing machine comprising the double-thread-loosening mechanism

A double thread loosening and sewing machine technology, which is applied to the thread cutting mechanism, sewing machine components, cloth pressing mechanism, etc. in the sewing machine, can solve the problem of no thread loosening, and achieve the effect of improving the thread loosening method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] A double thread release mechanism for a sewing machine and a sewing machine including the same according to an embodiment of the present invention will be described below with reference to the accompanying drawings. In the following description, numerous specific details are set forth in order to enable those skilled in the art to better understand the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without some of these specific details. Furthermore, it should be understood that the invention is not limited to the particular embodiments described. Accordingly, the following examples and advantages are for illustration only and should not be viewed as limitations on the claims unless expressly stated in the claims.

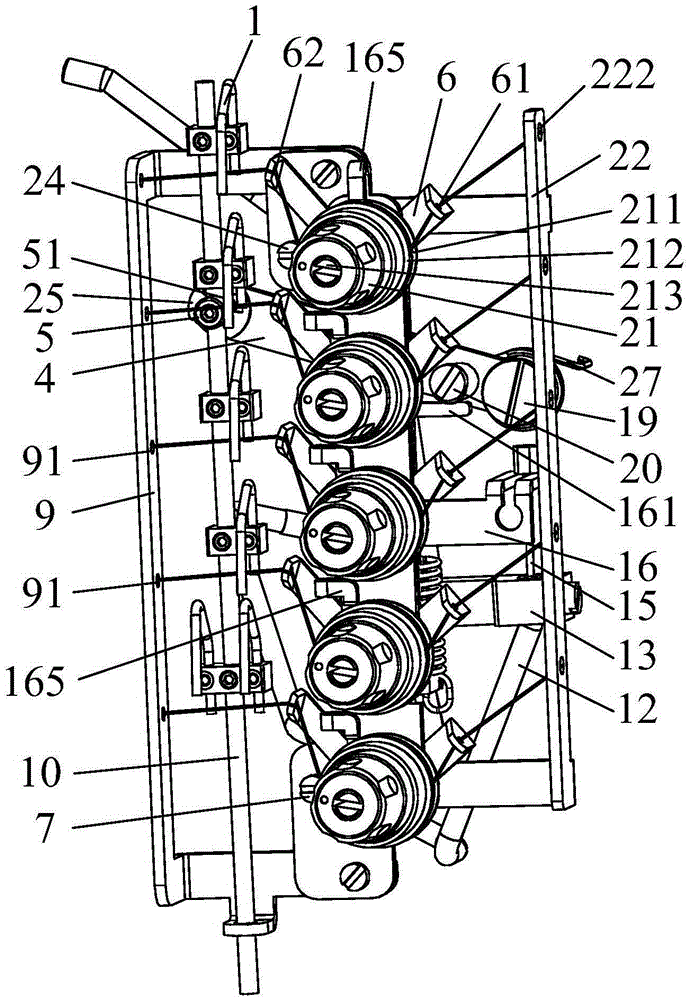

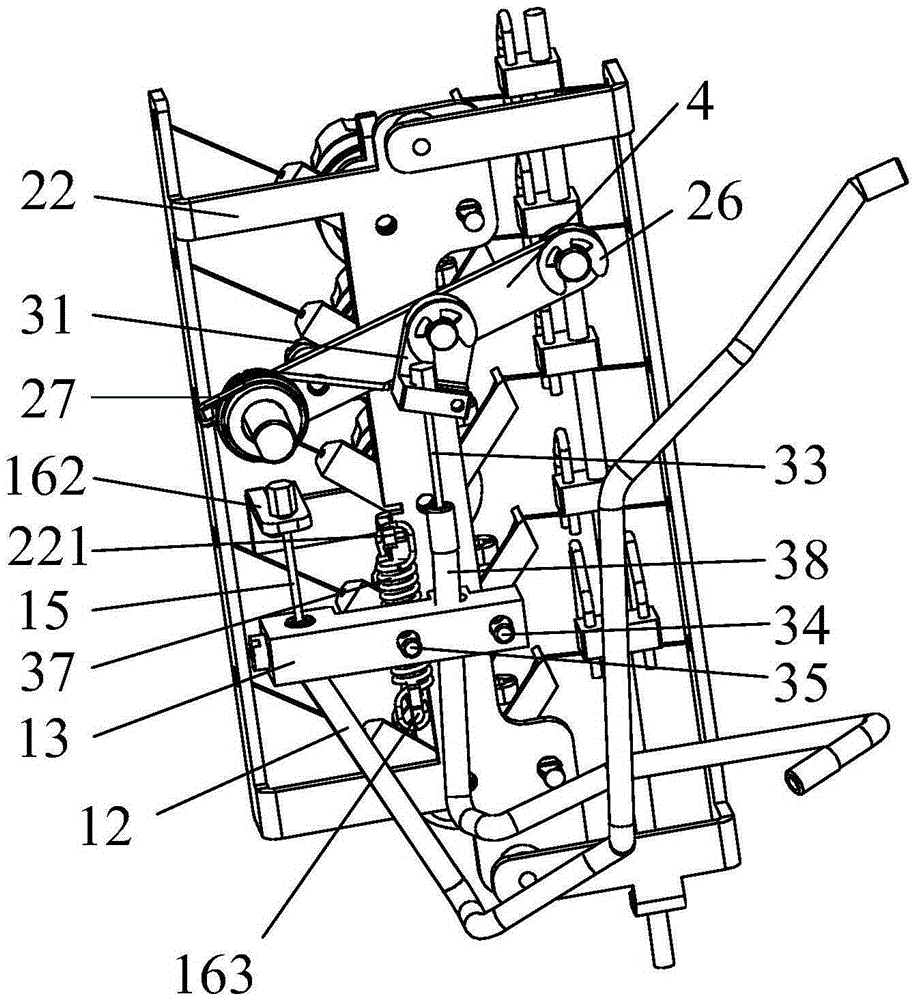

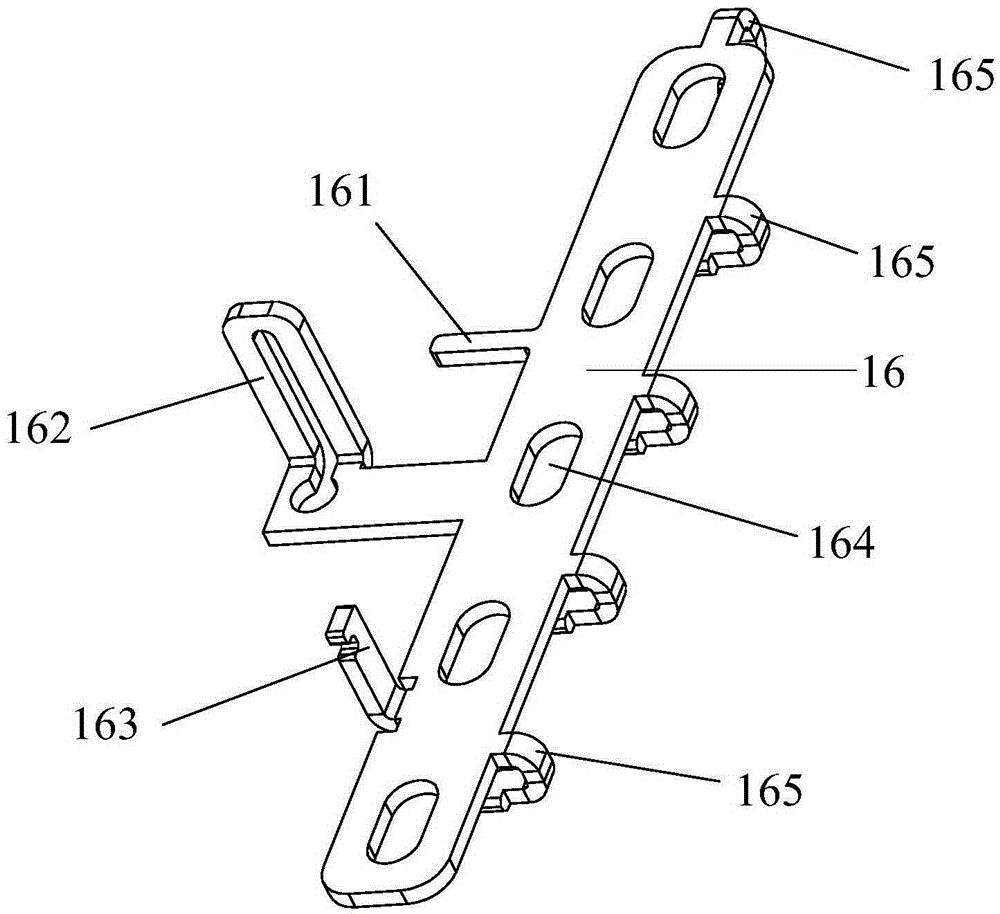

[0049] figure 1 and figure 2 Shown is a double thread release mechanism for a sewing machine according to the present invention, the double thread release mechanism includes a thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com