Method for removing turbidity of liquor base

A technology of base wine and liquor, applied in the preparation of alcoholic beverages, etc., can solve the problems of temperature limitation, volume increase, loss of trace components, etc., and achieve the effects of cost saving, small volume and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The experimental materials are: freshly steamed Luzhou-flavor liquor base liquor, which comes from Luzhou Laojiao.

[0041] The experimental instrument is a distillation tower, and the parameters are:

[0042] Maximum operating temperature: 200°C;

[0043] Processing capacity: 500ml / h raw material;

[0044] Tower diameter: 32mm; packing height: 2.5m (the total equipment height is about 4.1m); divided into 3 sections, one section is 0.9m, the second section is 0.8m, and each section has 2 side ports;

[0045] Packing: 2.5×2.5mm (316L stainless steel θ mesh ring);

[0046] Kettle volume: 3000ml, heating power: 1000w;

[0047] Insulation sleeve diameter: 80 ~ 100mm;

[0048] Heating power of heat preservation section (three sections): 500w each;

[0049] Backflow controller: adjustable from 0 to 99 seconds;

[0050] With computer interface and software, it can collect and display the temperature of kettle heating, tower top and tower kettle, and can control the given...

Embodiment 2

[0056] The experimental materials are: freshly steamed Luzhou-flavor liquor base liquor, which comes from Luzhou Laojiao.

[0057] The experimental instrument is a distillation tower, and the parameters are:

[0058] Maximum operating temperature: 200°C;

[0059] Processing capacity: 500ml / h raw material;

[0060] Tower diameter: 32mm; packing height: 2.5m (the total equipment height is about 4.1m); divided into 3 sections, one section is 0.9m, the second section is 0.8m, and each section has 2 side ports;

[0061] Packing: 2.5×2.5mm (316L stainless steel θ mesh ring);

[0062] Kettle volume: 3000ml, heating power: 1000w;

[0063] Insulation sleeve diameter: 80 ~ 100mm;

[0064] Heating power of heat preservation section (three sections): 500w each;

[0065] Backflow controller: adjustable from 0 to 99 seconds;

[0066] With computer interface and software, it can collect and display the temperature of kettle heating, tower top and tower kettle, and can control the given...

Embodiment 3

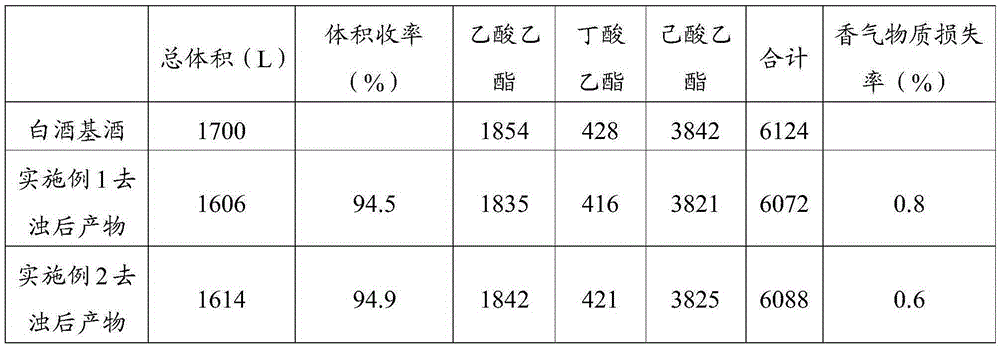

[0072] Adopt gas chromatography internal standard method to detect the content of higher fatty acid ethyl ester (ethyl palmitate, ethyl oleate, ethyl linoleate) in liquor base liquor and embodiment 1~2 gained fraction 1~5, the result As in Table 1:

[0073] Table 1 Content of higher fatty acid ethyl ester

[0074]

[0075] Except for fraction five, fraction one and fraction three were not detected to contain higher fatty acid ethyl esters, indicating that the method provided by the present invention can effectively remove higher fatty acid ethyl esters, and the removal rate can reach 94.5%. Higher fatty acid ethyl esters are the main substances that cause the liquor base wine to become turbid after the alcohol is reduced. The present invention uses the content of these substances to measure the effect of removing turbidity. The results show that the method provided by the invention has a good effect of removing turbidity and can improve the quality of the finished wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com