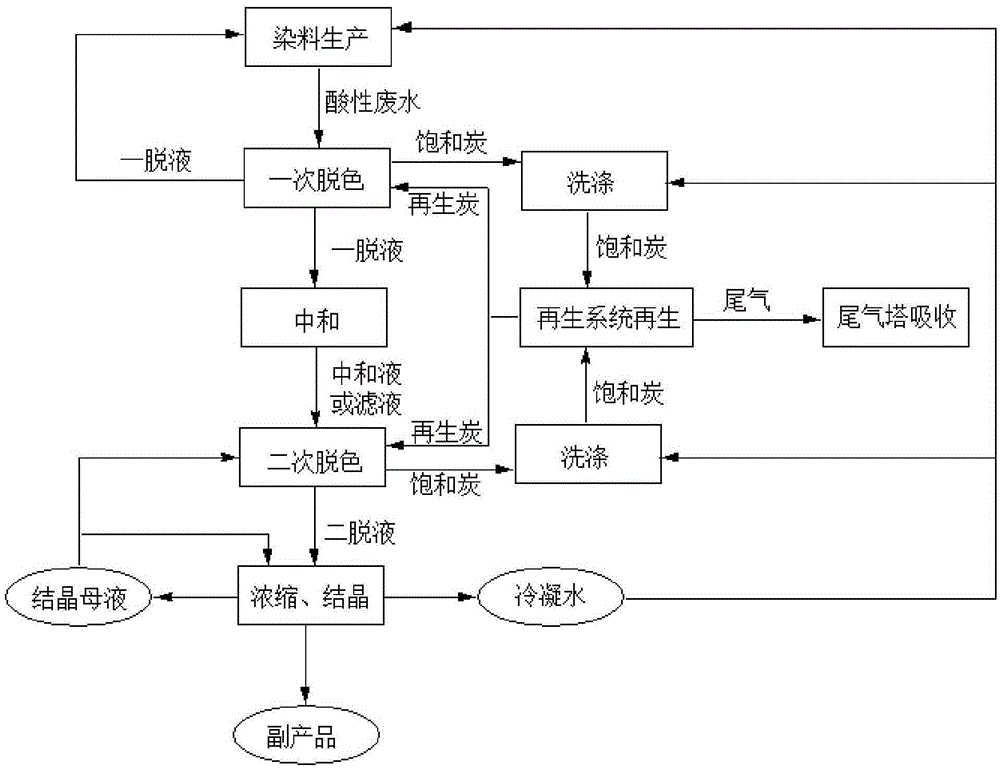

Continuous treatment method for dye industry acid wastewater

A technology for acidic wastewater and treatment methods, applied in multi-stage water treatment, water/sewage treatment, chemical instruments and methods, etc., can solve problems such as difficult treatment and secondary pollution, achieve significant energy saving and emission reduction, avoid waste residue generation, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

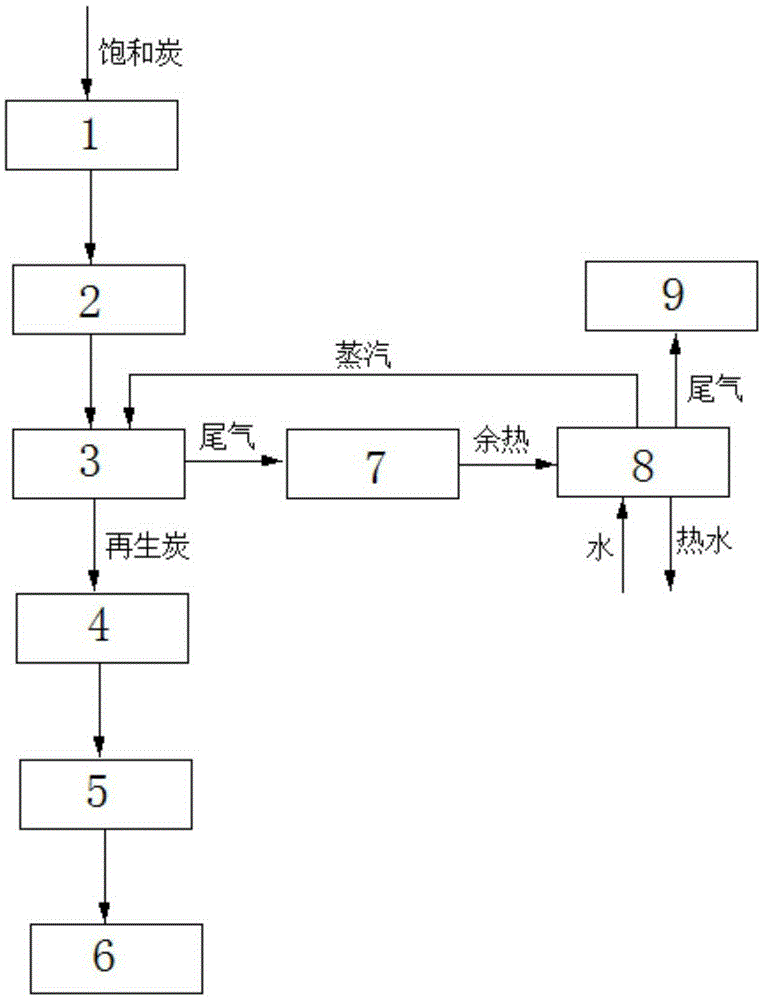

[0031] refer to figure 2 , the acid wastewater comes from the sulfuric acid wastewater in the dye production (sulfuric acid content is 5.68%, COD is 11380mg / L), the first desorption tower and the second desorption tower are built with a volume of 12m 3 The granular activated carbon adsorption column (granular activated carbon particle size 1.2 ~ 1.4mm), the neutralization device is a three-stage series neutralization pot, the physical filtration uses a bag filter, and the temperature of the primary furnace (3) of the regeneration furnace is controlled at 880 ° C, and the temperature of the secondary furnace is 880 ° C. (7) The temperature is 620°C, using flowmeters and valves to control the waste water to 5m 3 The / h flow rate enters the following steps, and the residence time of the first and second removals is controlled to 2.5h. The specific operations are as follows:

[0032] (A) Primary decolorization: Acidic wastewater enters the bottom of a desorption tower through a ...

Embodiment 2

[0040] Acidic wastewater comes from sulfuric acid wastewater in dye production (sulfuric acid content is 12.5%, COD is 12510mg / L), and the volume of a desorption tower built in four-stage parallel connection is 12m 3 Granular activated carbon adsorption column (granular activated carbon particle size 1.2 ~ 1.4mm), the volume of the second desorption tower built in parallel is 12m 3 The granular activated carbon adsorption column (granular activated carbon particle size 1.2 ~ 1.4mm), the neutralization device is a three-stage series neutralization pot, the temperature of the first furnace of the regeneration furnace is controlled at 880 ° C, the temperature of the second furnace is 625 ° C, and the flow rate of the first waste water is controlled at 2.5 m 3 / h, residence time 4.8h, two off flow rate 5m 3 / h, residence time 2.5h, concrete steps are operated by the method described in embodiment 1, and difference is to add liquid ammonia to neutralize to pH value 6.0 during neutr...

Embodiment 3

[0042] The acidic wastewater comes from the wastewater containing hydrochloric acid in dye production (the content of hydrochloric acid is 6.36%, and the COD is 16940mg / L). Both the first desorption tower and the second desorption tower have a built-in primary volume of 12m 3 The granular activated carbon adsorption column (granular activated carbon particle size 1.2 ~ 1.4mm), the neutralization device is a three-stage series neutralization pot, the physical filtration uses a bag filter, and the temperature of the first furnace of the regeneration furnace is 880 ° C, and the temperature of the second furnace is 600 ° C Using flow meters and valves to control waste water at 4m 3 The / h flow rate enters the wastewater treatment system, and the first and second removal residence times are controlled for 3h. The specific steps are operated according to the method described in Example 1. The difference is that part of the first removal is used as synthetic bottom water for dye produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com