Automatic vehicle hook for motor train unit traction vehicle

A technology for automatic couplers and EMUs, applied in traction devices, railway car body parts, transportation and packaging, etc., can solve the problems of reducing the total length of the tractor and the towed vehicle, low automation level, high labor intensity, etc., and achieve improvement Labor productivity, reduced labor intensity, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

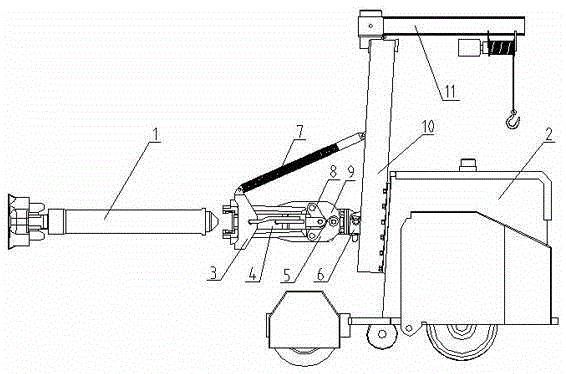

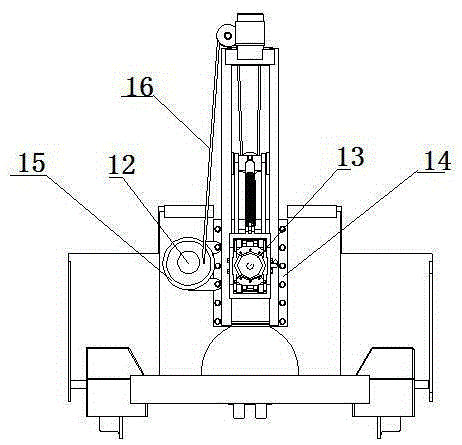

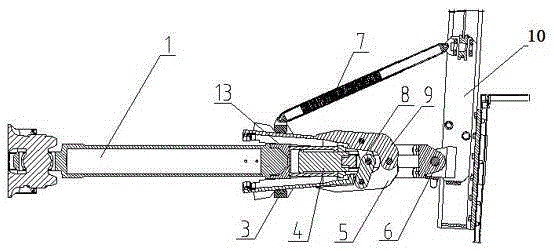

[0015] refer to figure 1 , figure 2 , the present invention includes a small electric tractor 2, a locking mechanism for connecting and locking the coupler of the EMU, a device for lifting the locking mechanism, a gravity balance device for adjusting the lifting and lowering of the locking mechanism, and a slideway 10 for lifting and lowering the locking mechanism. , the slideway is a channel steel structure and fixed on the small electric tractor 2, the locking mechanism is composed of a hydraulic cylinder 4, upper and lower pressure plates 9, 5, connecting rod 8, and a locking seat 3, and the upper and lower pressure plates 9 and 5 are connected through the connecting pin Rotational connection, the connecting pin shaft is fixed on the floating connection seat 6, the two ends of the connecting rod 8 are rotationally connected with the upper and lower pressure plates, the center of the connecting rod is connected with the hydraulic cylinder 4, the locking seat 3 is set on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com