Small-stroke large-corner dumper lifting machine

A technology of lifting mechanism and large turning angle, which is applied in the direction of loading and unloading vehicles, vehicles used for freight transportation, and vehicles with inclined bearing movement, etc. It can solve the problems of increasing the distance between beams, the length of hydraulic cylinders, and the difficulty of accommodating hydraulic cylinders. To achieve the effect of reasonable structure setting and avoiding excessive load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

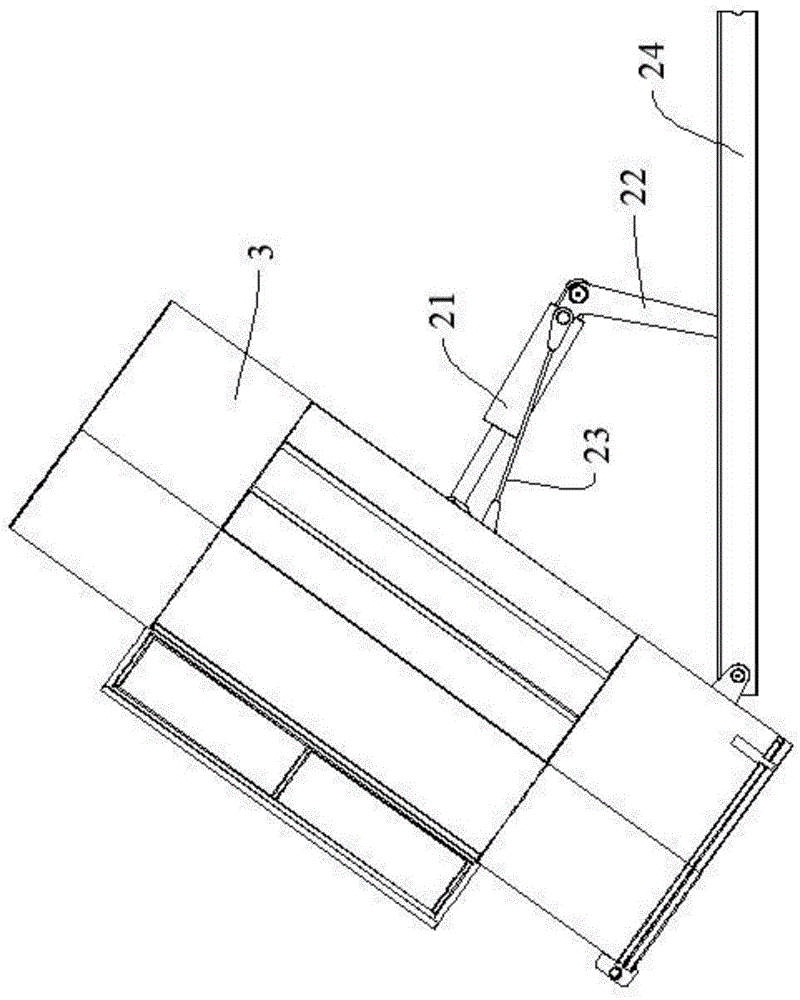

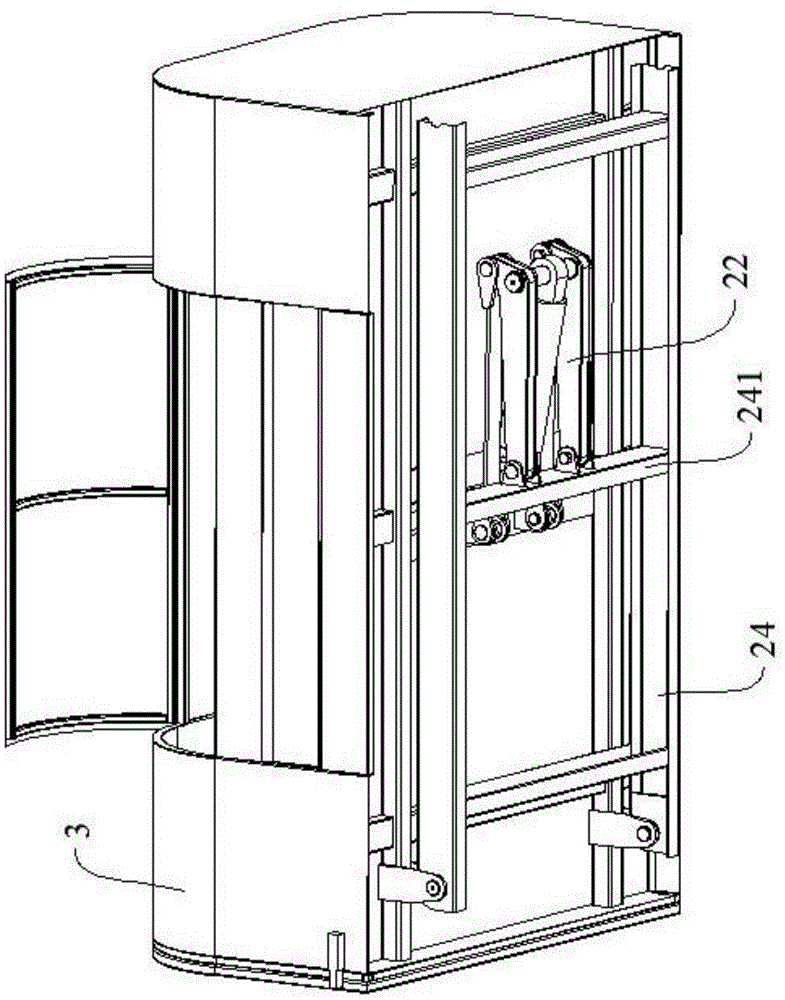

[0018] as attached Figure 1~5 As shown, a dump truck lifting mechanism with a small stroke and a large rotation angle includes: a lifting cylinder 21, a support arm 22, a lifting arm 23, and an attached frame 24; wherein, the fixed end 221 of the support arm is pivotally connected to the attached frame 24 On the side wall of the beam 241 and the side wall is the side close to the driver's cab, the fixed end 221 of the support arm can only rotate around the pivot, but cannot be lifted relative to the attached vehicle frame 24, and the other end of the support arm 22 is the support arm Lifting end 222, the lifting end 222 of the support arm is pivotally connected to one end of the lifting cylinder 21, and the other end of the lifting cylinder 21 is pivotally connected to the bottom of the carriage 3; the "lifting cylinder" involved in the present invention can be a commonly used hydraulic cylinder Cylinder or pneumatic cylinder, etc., as long as the purpose of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com