Transformer substation inspection robot system for detecting equipment in box and method thereof

An inspection robot and equipment detection technology, applied in the direction of instruments, manipulators, electrical components, etc., can solve the problems of inability to open the box, reduce the practicality of the substation inspection robot, and cannot realize the detection and operation of equipment in the box, etc., to achieve expansion Device-wide effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

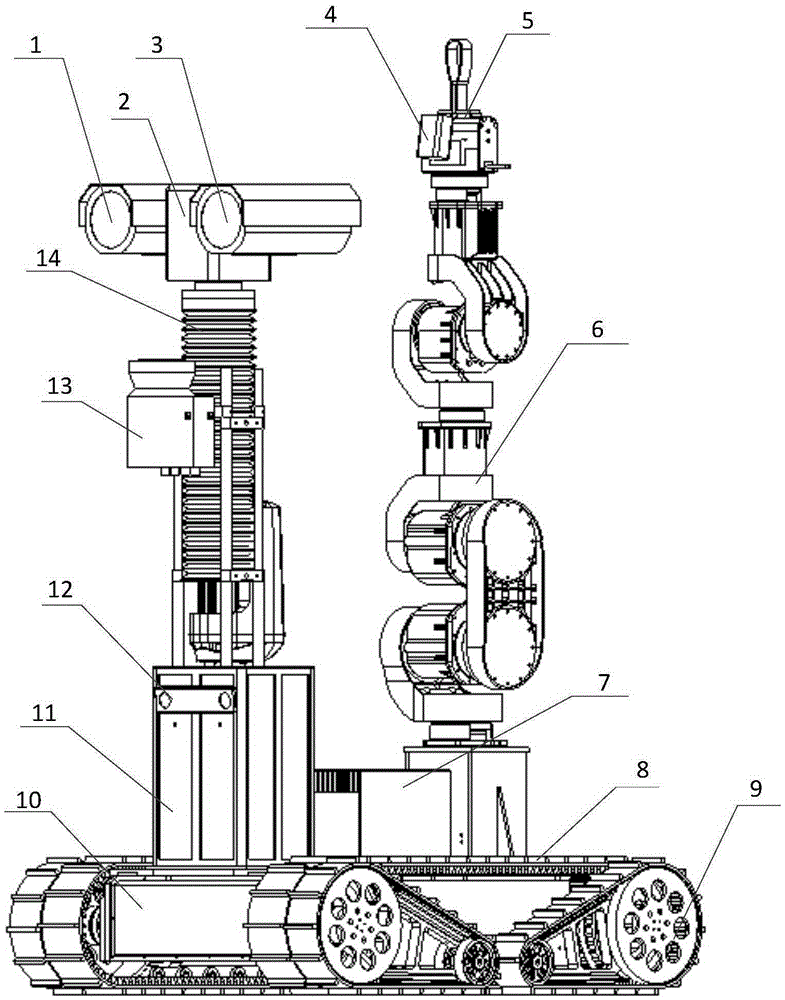

[0039] Such as figure 1 As shown, a substation inspection robot with a mechanical arm includes an inspection robot body and a mechanical arm installed on the body, wherein the robot body includes a wheel-track chassis 10, a cloud platform 2, a platform lifting mechanism 14, a visible light Camera 1, thermal imaging camera 3, laser sensor 13, binocular vision sensor 12 and industrial computer 7. Wherein, the walking mechanism carries the robot body to walk, the mechanical arm is arranged on the walking mechanism, and the industrial computer 7 controls the operation of the acquisition device and the walking mechanism;

[0040] The acquisition device includes a camera, an infrared thermal imager 3, a visual sensor 12 and a laser sensor 13, the visible light camera 1 and the infrared thermal imager 3 are arranged on the cloud platform 2, and the cloud plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com