Welding process quality on-line monitoring analysis equipment and monitoring analysis method thereof

A technology for analyzing equipment and welding process, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high cost, less welding quality monitoring, high product rejection rate, saving labor costs and reducing transformation cost, the effect of improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

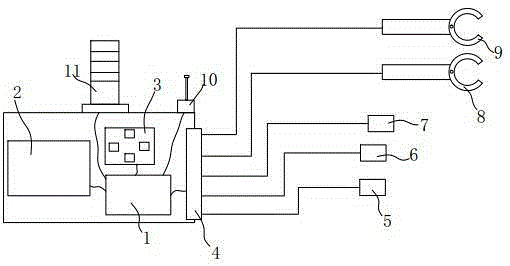

[0026] A welding monitoring and analysis equipment, comprising

[0027] Current sensor 9: the current sensor 9 is installed on the welding circuit of the welding machine for detecting the welding current;

[0028] Voltage sensor 8: the voltage sensor 8 is installed on the welding circuit of the welding machine for detecting the welding current;

[0029] Air pressure sensor 7: the air pressure sensor 7 is installed on the air supply pipe of the welding machine to detect the air pressure of the air supply pipe;

[0030] Temperature sensor 6: the temperature sensor 6 is installed on the cooling water pipe or the welding point, and is used to detect the temperature of the cooling water pipe and the welding temperature;

[0031] Gas flow sensor 5: the gas flow sensor 5 is installed on the intake pipe for detecting the intake flow;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com