A kind of auxiliary tooling for clutch armature of die-casting machine assembly line

An assembly line and auxiliary tooling technology, which is applied in the field of clutch armature auxiliary tooling in the assembly line of die-casting machines, can solve problems such as labor intensity, poor safety, and poor fixation of inclined iron base and coupling body, so as to reduce labor intensity and improve assembly efficiency , The effect of convenient screw assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

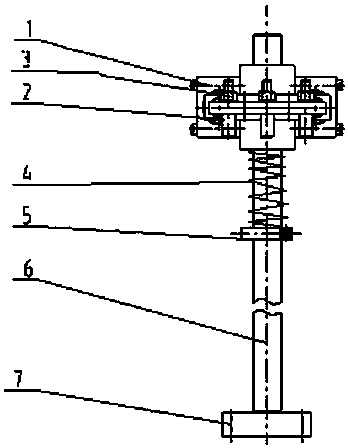

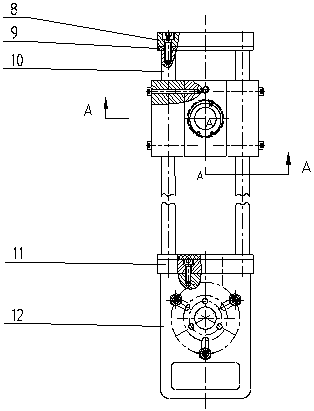

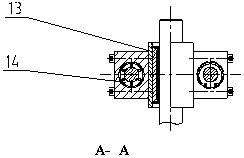

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0031] During specific implementation: if Figure 1-3 As shown in the figure, an auxiliary tooling for the clutch armature of a die-casting machine assembly line includes a coupling body clamping part for clamping and fixing the three sides of the coupling body triangle, and the coupling body clamping part is connected with a horizontally outwardly extending The transverse connecting rod 10, the end of the transverse connecting rod 10 away from the clamping part of the coupling body is provided with a fixed support part and can be fixedly supported downward to the ground by the fixed support part.

[0032] In this way, when the auxiliary device is in use, one end of the transverse connecting rod is fixedly supported to the ground by the fixed support part, and the clamping part of the coupling body at the other end of the transverse connecting rod realizes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com