Flask for lost foam casting

A technology of lost foam casting and sand box, which is applied in the direction of casting molding equipment, molding boxes, manufacturing tools, etc., and can solve the problems of poor appearance quality of casting products, easy pinholes in castings, and poor evacuation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

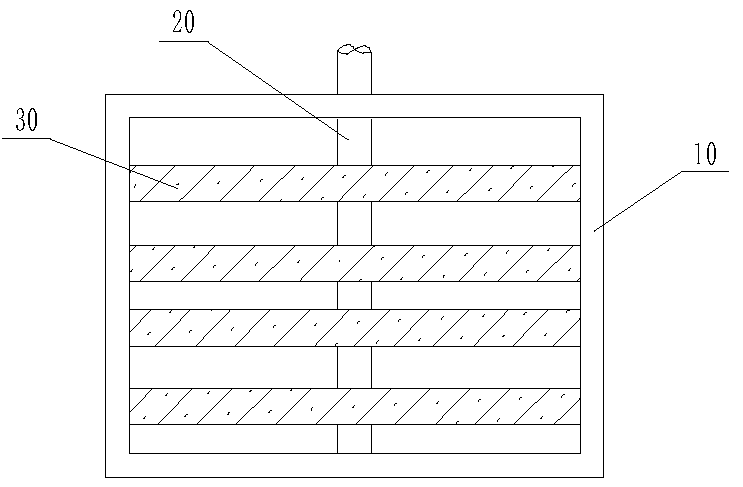

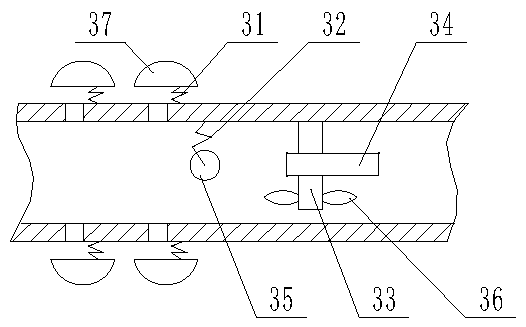

[0015] The reference numerals in the accompanying drawings of the description include: box body 10 , connecting pipe 20 , air suction pipe 30 , elastic member 31 , flexible member 32 , rotating shaft 33 , cam 34 , steel ball 35 , blade 36 , and block 37 .

[0016] The embodiment is basically as attached figure 1 and figure 2 Shown: a sand box for lost foam casting, including a box body 10, the bottom of the box body 10 is provided with four suction pipes 30 arranged side by side, and the box body 10 is also provided with a suction pipe for connecting adjacent 30 connecting pipe 20. A suction hole is arranged on the side wall of the air suction pipe 30, and an elastic member 31 is installed on the outer wall of the air suction pipe 30, and the elastic member 31 is a first compression spring. The end of the elastic member 31 is equipped with a stopper 37 to prevent the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com