A multifunctional integrated pre-filter for air source system and its filtering method

A pre-filter, multi-functional technology, applied in membrane filters, chemical instruments and methods, filtration and separation, etc., can solve problems such as increasing failure points and manufacturing costs, connecting pipelines, and air leakage risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

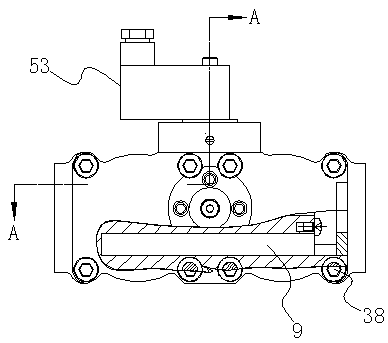

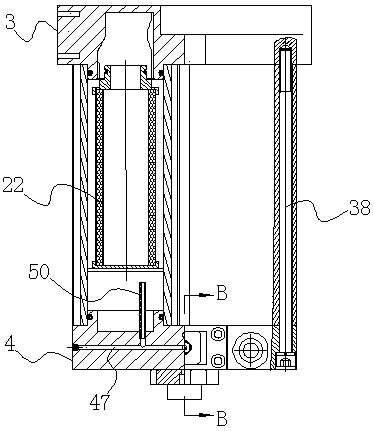

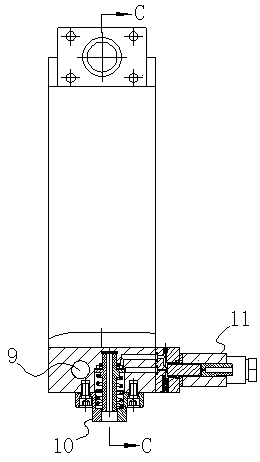

[0050] Example: such as Figure 1 to Figure 4 As shown, a multifunctional integrated pre-filter of the air source system includes a filter cartridge one 1, a filter cartridge two 2, an upper connecting plate 3 arranged on the top of the filter cartridge one 1 and the top of the filter cartridge two 2 and The lower connecting plate 4 arranged on the bottom of the filter cartridge one 1 and the bottom of the filter cartridge two 2, the air inlet 5 is arranged on one side of the upper connecting plate 3 and the air inlet 5 is located near the side of the filter cartridge one 1 , the air outlet 6 is arranged on the other side of the upper connecting plate 3 and the air outlet 6 is located on one side of the filter cartridge two 2, and an air channel 7 is also arranged inside the upper connecting plate 4, the air inlet 5 and the outlet The air port 6 communicates with the filter cartridge 1 and the filter cartridge 2 through the air channel 7, so that after the compressed air enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com