Integrally-formed shoe sole article with dual density and manufacturing method thereof

A dual-density, one-piece technology, applied to shoe soles, footwear, household components, etc., can solve problems such as unbearable torsion, soft soles, and tear resistance, so as to reduce mold opening resistance, relieve joint pressure, and facilitate mold opening The effect of exerting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

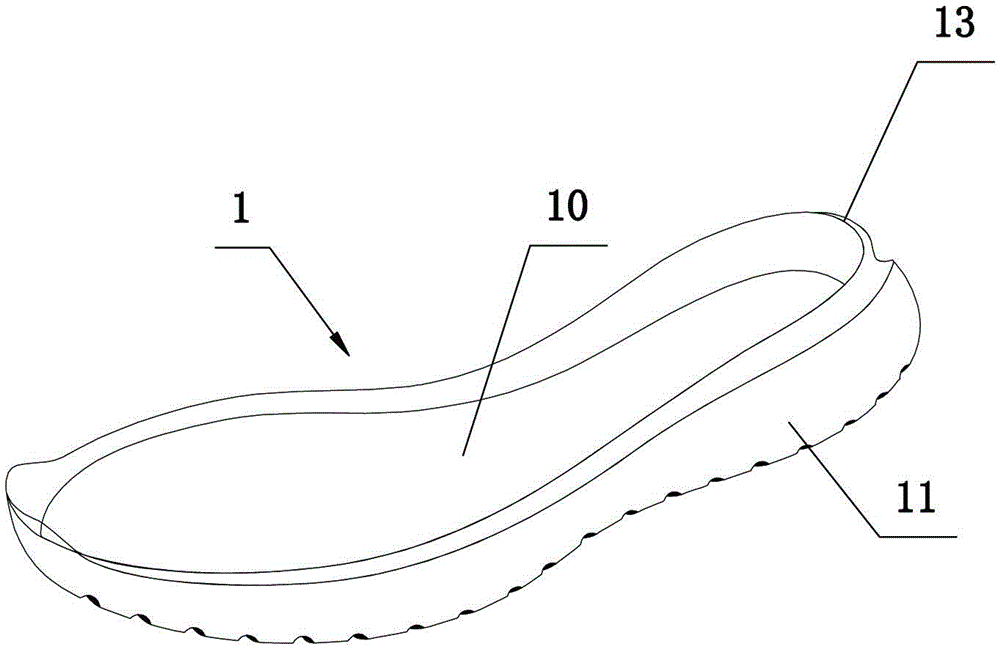

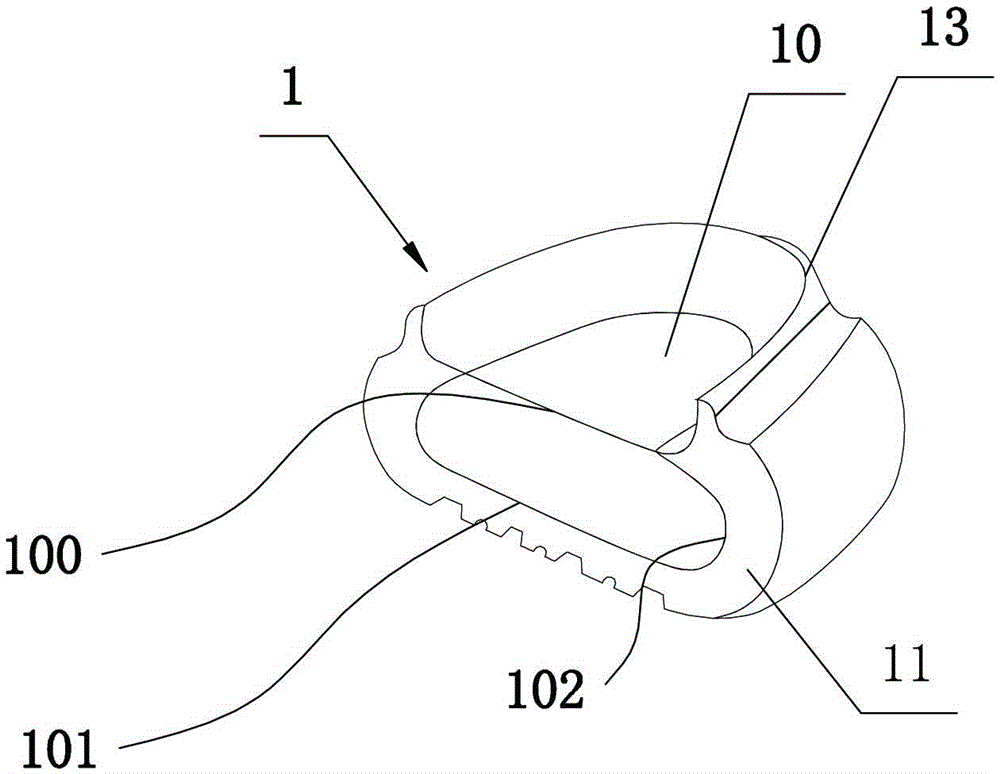

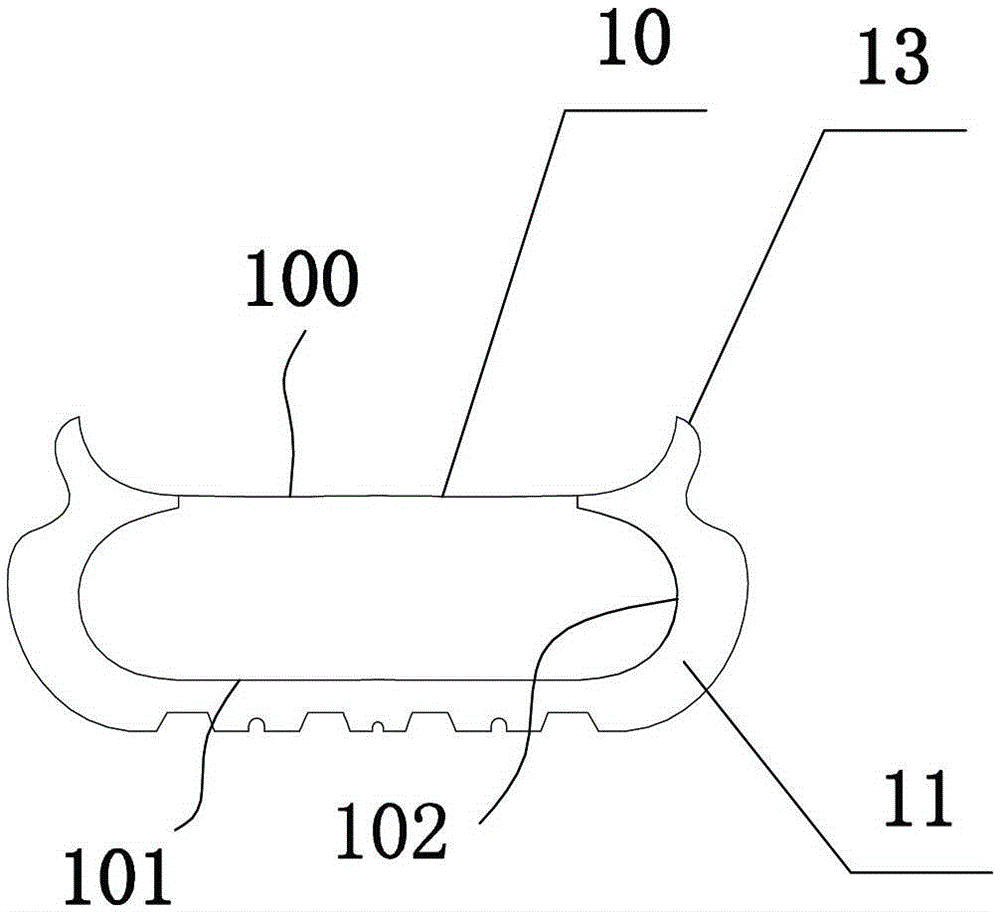

[0036] refer to Figure 1-Figure 6 . A shoe sole object 1 with dual density integral molding, comprising a first density portion 10 and a second density portion 11 partially covering the first density portion 10, the first density portion 10 includes a first top surface 100. A first bottom surface 101 parallel to and opposite to the first top surface 100 and an arc-shaped connection surface 102 extending from the periphery of the first top surface 100 to the periphery of the first bottom surface 101, on the second density portion 11 There is a groove body 110 for accommodating the first density part 10, the groove body 110 includes a notch 111 matching the size of the first top surface 100, located directly below the notch 111 and connected to the The first bottom surface 101 is adapted to the groove bottom 112 and an arc-shaped wall surface 113 formed by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com