A kind of purple sweet potato jelly candy and its processing technology

A potato jelly candy and processing technology, which is applied in the field of purple potato jelly candy and its processing, can solve the problems of product aging and taste impact, and achieve the effects of increased solubility, low sweetness, and gel performance protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

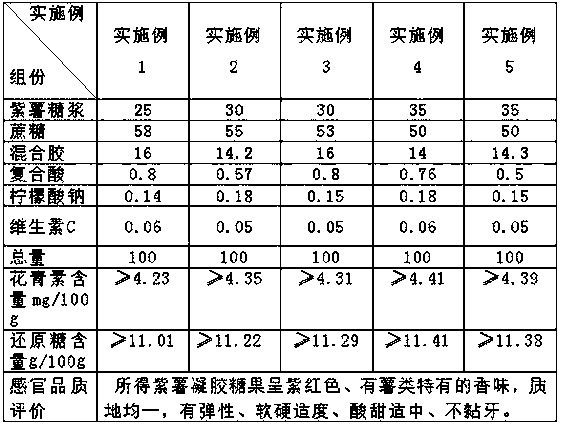

Examples

Embodiment 1

[0029] The technique adopted in embodiment 1 is as follows:

[0030] (1) Production of purple sweet potato syrup: Weigh purple sweet potato powder, add about 4-6 times of water, so that the purple sweet potato powder is completely dispersed evenly. Then gelatinize at 100°C for 10 minutes. Adjust the pH of the gelatinized slurry to 6.5, add α-amylase, liquefy at 96°C for 10-15 minutes, boil for 5 minutes, cool to 50-60°C, and centrifuge at 5000r / min for 15-20 minutes to obtain the upper layer liquid, adjust the pH to 6. 4. Add β-amylase at an enzyme dosage of 160U per gram of starch, α-glucosidase at an enzyme dosage of 180U per gram of starch, and pullulanase at an enzyme dosage of 48U per gram of starch, at 50°C Enzymolysis for 30 hours, then boiled for 5 minutes, then concentrated to a moisture content of ≤30%, sterilized by microwave for 2 minutes, sealed and stored for later use.

[0031] The specific enzyme amount Ma (g) can be calculated according to the following form...

Embodiment 5

[0039]The technology that embodiment 5 adopts is different from the content of embodiment 1 as follows:

[0040] The production steps of purple potato jelly candy:

[0041] Add purple sweet potato syrup and sucrose into the batching pot according to the formula amount, and heat while stirring. When the sucrose is completely dissolved and produces a burnt aroma, add 70°C sodium alginate solution, stir while adding, until the temperature reaches 95°C, and then add 60 ℃ gelatin solution, stir quickly and mix well, and pay attention to prevent air bubbles from mixing in, continue to boil and stir until the water content is about 17%. When the temperature of the paste-like sugar body drops to 90°C, add glucono-δ-lactone, stir and mix quickly, and when the massecuite cools down to about 75°C, add citric acid, vitamin C and sodium citrate, stir well, Cool and pour the mold, let stand at 15°C for about 8 hours to gel, demould, cut into sugar cubes about 3cm×2cm, or cut into pieces ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com