A detachable and hanging peanut combine harvester

A technology for combine harvesters and peanuts, which is applied in the direction of excavator harvesters, harvesters, agricultural machinery and implements to achieve good harvesting effect, good clamping and conveying effect, and lowering the height of the whole machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

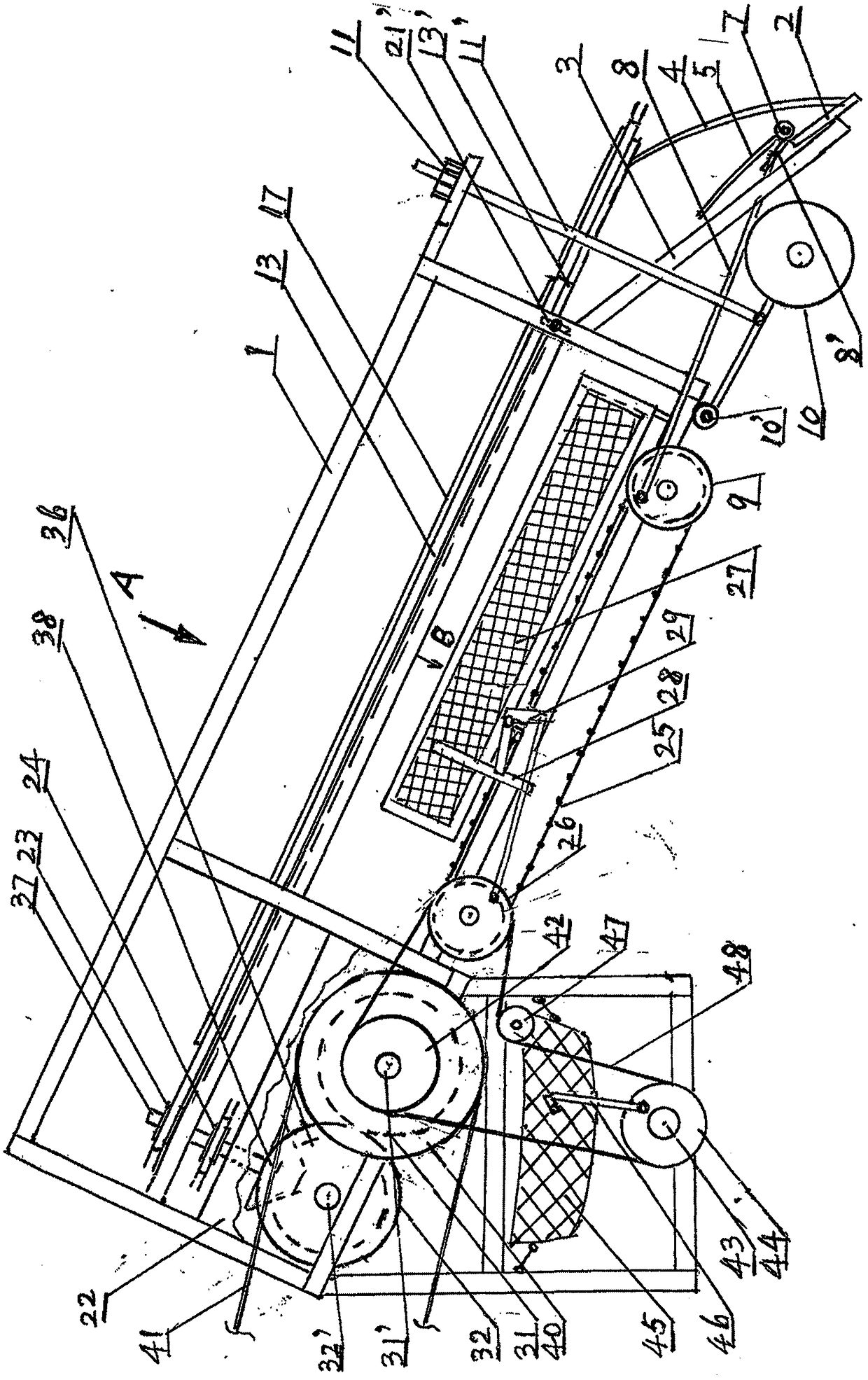

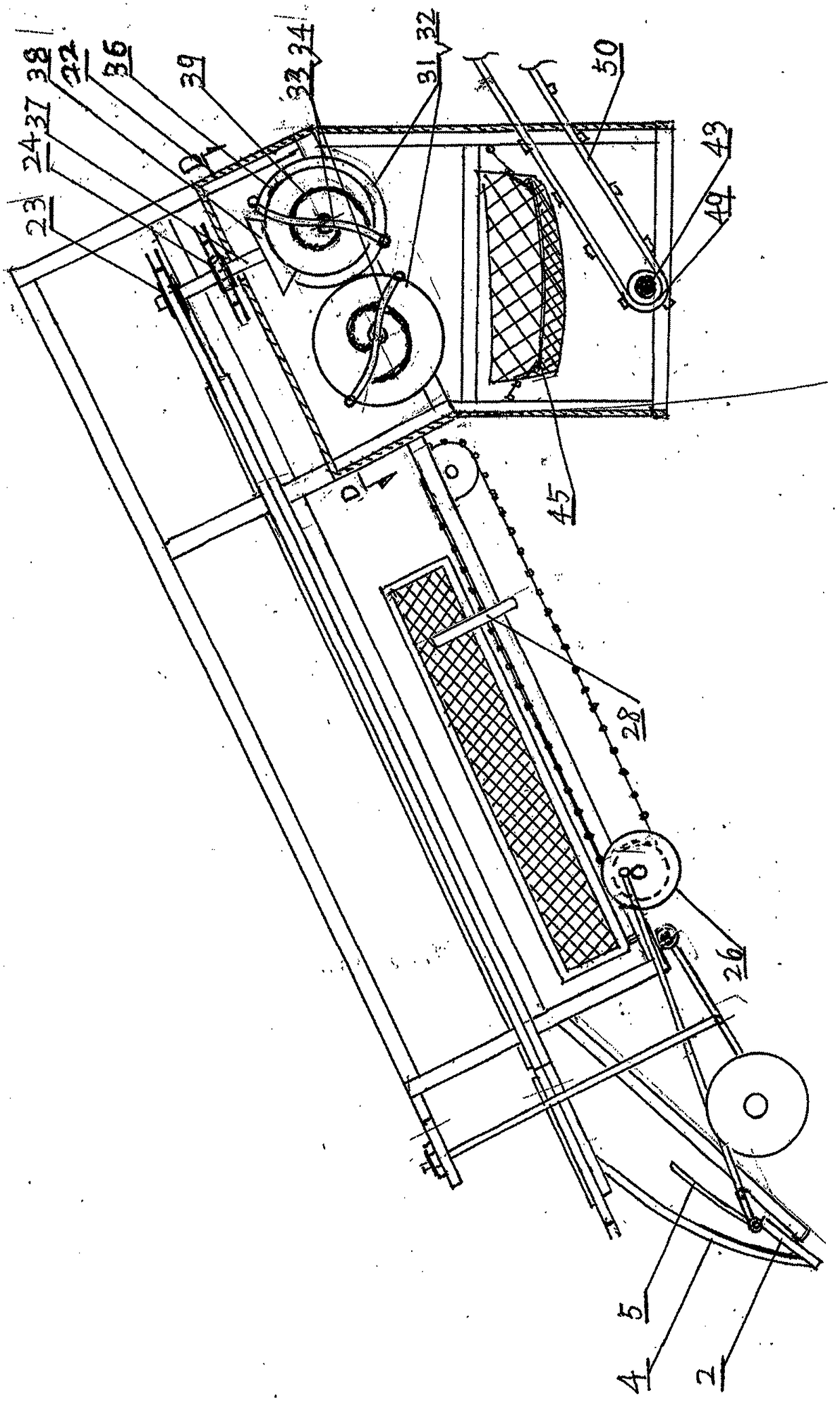

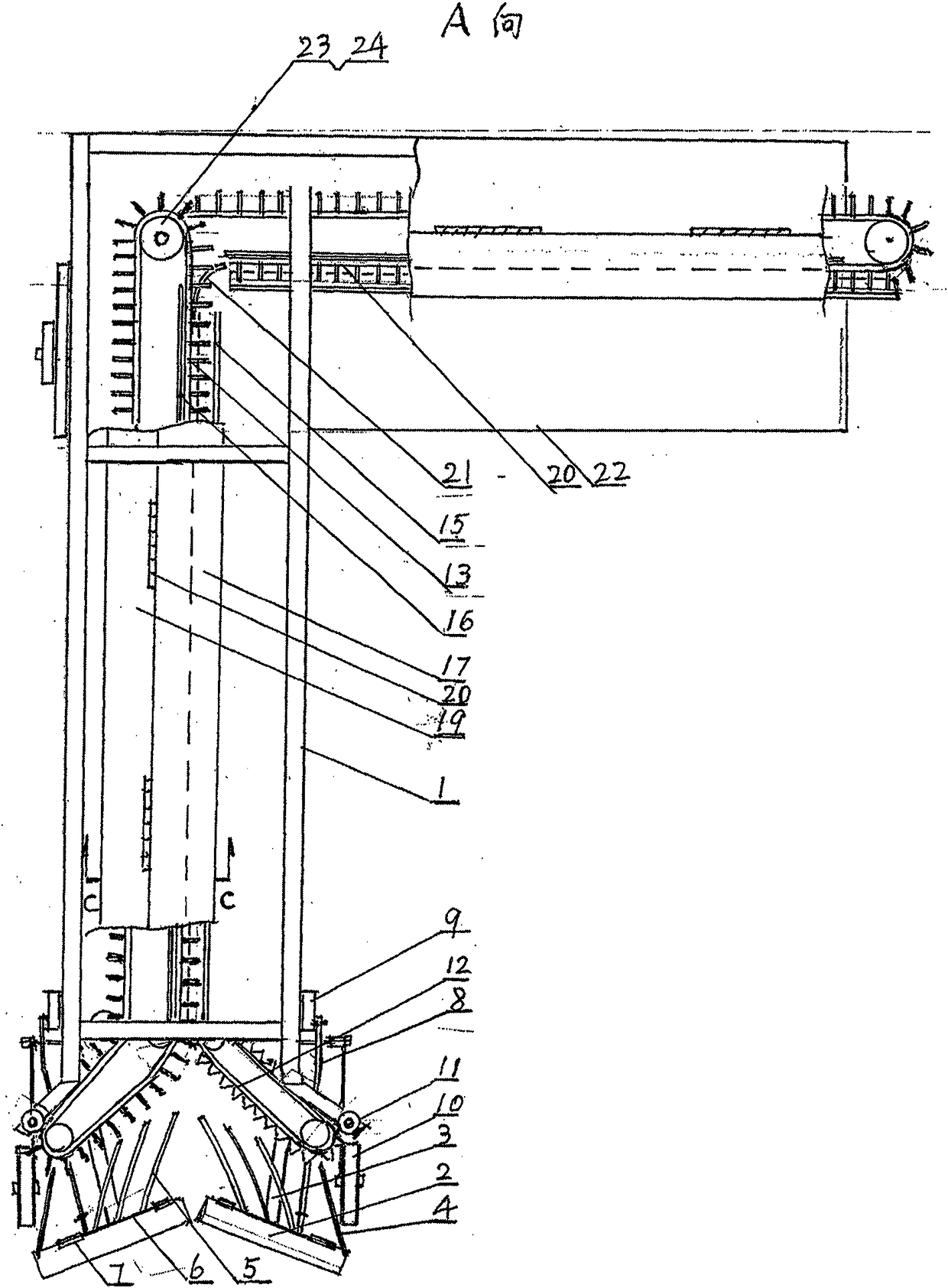

[0017] Instructions attached figure 1 , 2 , 3 provides a specific implementation. It includes a frame 1, a harvesting device, a conveying device, a fruit removing device, a cleaning device, a fruit collecting device and a transmission device. The machine can be installed on the front end of the tractor in a front-end form, and it can be unloaded from the tractor after the harvest season, and the tractor can be used for other purposes.

[0018] The conveying device of this machine is a single conveying chain with closed-loop operation, including an inclined lifting conveying chain 13 and a horizontal horizontal conveying chain 20. The inclined lifting conveying chain and the transverse horizontal conveying chain are arranged in a T shape. A fruit-threshing device is set under the horizontal conveying chain.

[0019] The chain link of the conveyor chain of the present invention has two upper and lower racks 14 protruding to one side, and the corresponding side of the two rack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com