A straightening machine for straightening large-diameter cables

A large-diameter, straightening machine technology, applied in the direction of cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems of small pressing force and inability to meet the straightening requirements of large-diameter cables, so as to prolong the service life and avoid Mutual frictional damage and labor-saving operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

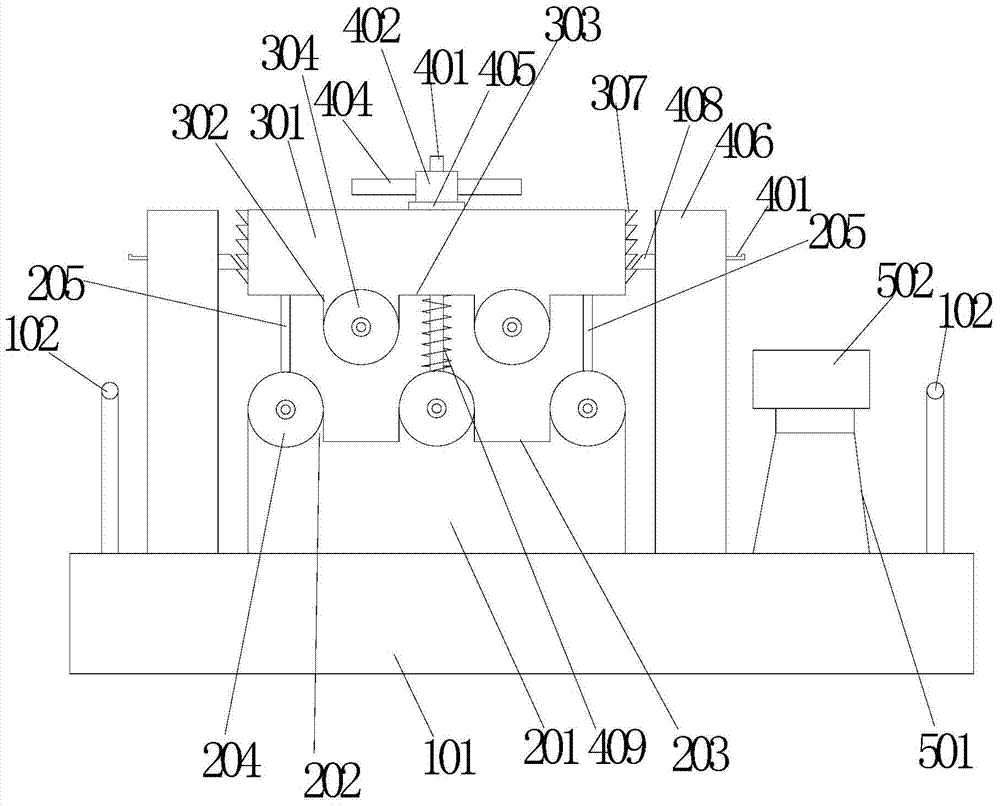

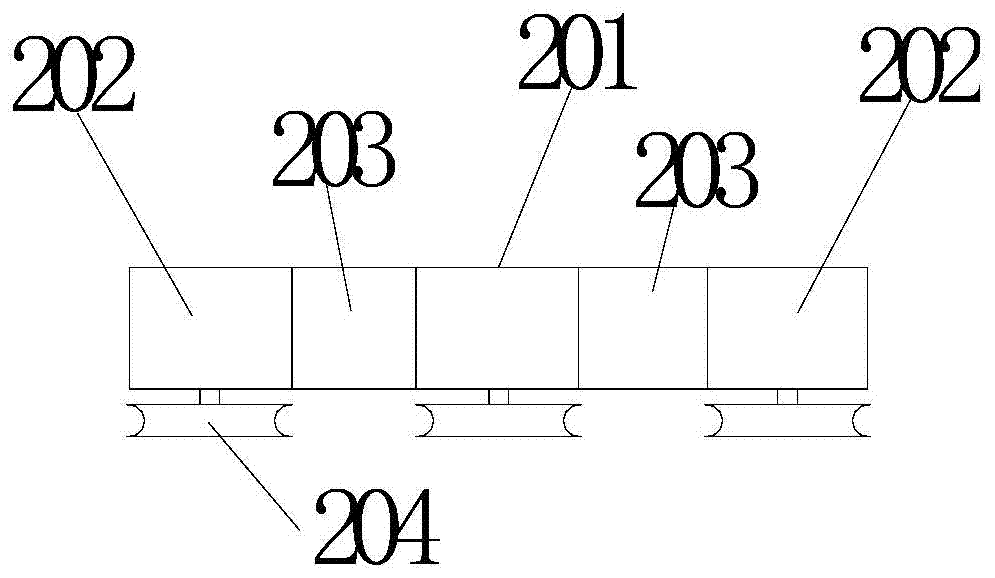

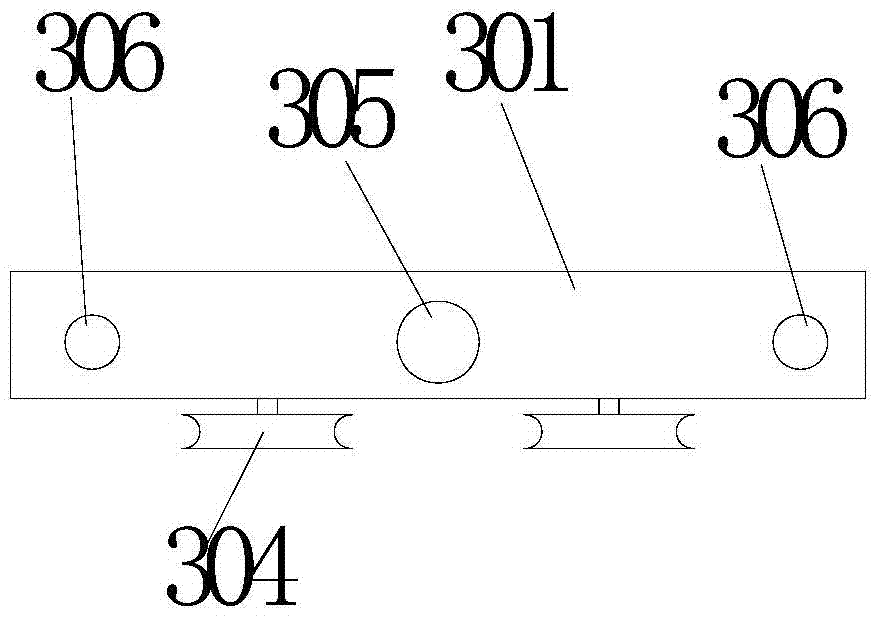

[0041] see Figure 1 ~ Figure 3 The straightening machine for straightening large-diameter cables provided in this embodiment includes a base 101, a fixed plate 201 and a moving plate 301, the fixed plate 201 is fixedly connected to the base 101, and the moving plate 301 is provided with a The pressing mechanism for the movement of the moving plate 301, the side of the fixed plate 201 away from the base 101 is provided with a plurality of first protrusions 202 evenly spaced, and a first groove 203 is formed between two adjacent first protrusions 202, A straightening wheel 204 is provided on the first projection 202, and a plurality of second projections 302 that can be embedded in the first groove 203 are provided on the side of the moving plate 301 close to the fixed plate 201. Tensioner 304. In this embodiment, three first protrusions 202 are evenly spaced on the side of the fixing plate 201 away from the base 101. Of course, there may be two, four, or five protrusions. Tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com