Method for detecting concrete structure crack width by means of fiber sensor

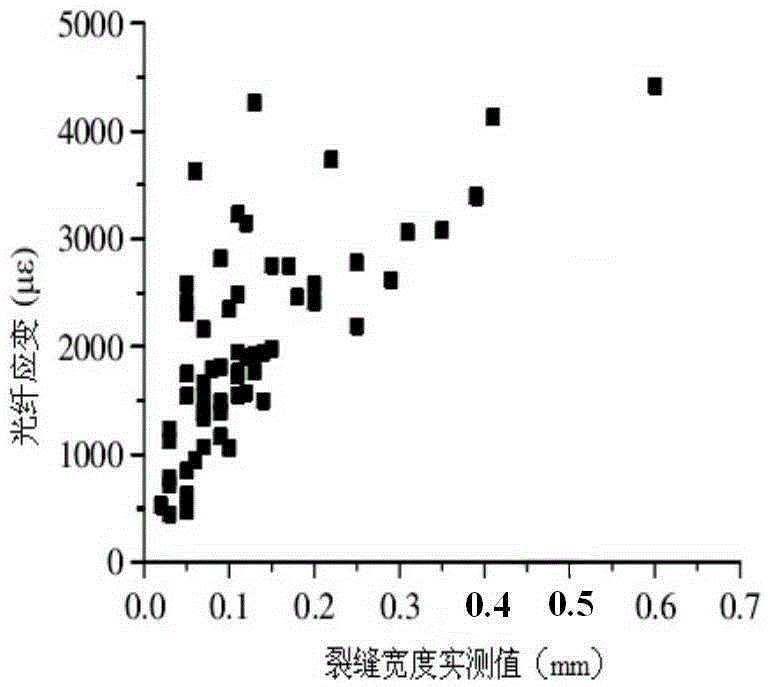

A concrete structure and optical fiber sensor technology, which is applied in the direction of using optical devices, instruments, measuring devices, etc., can solve the problems of inaccurate measurement of crack width, etc., and achieve the effects of reducing labor intensity, improving calculation accuracy, and fast calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

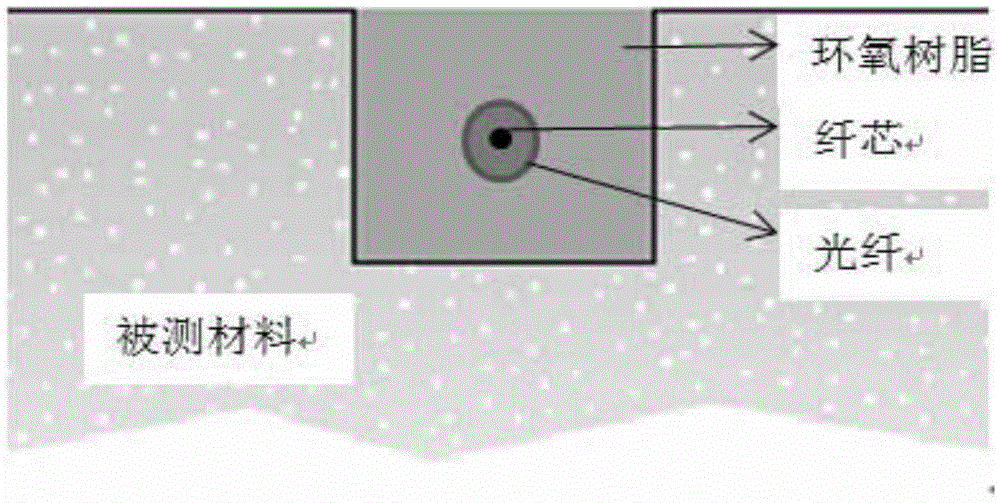

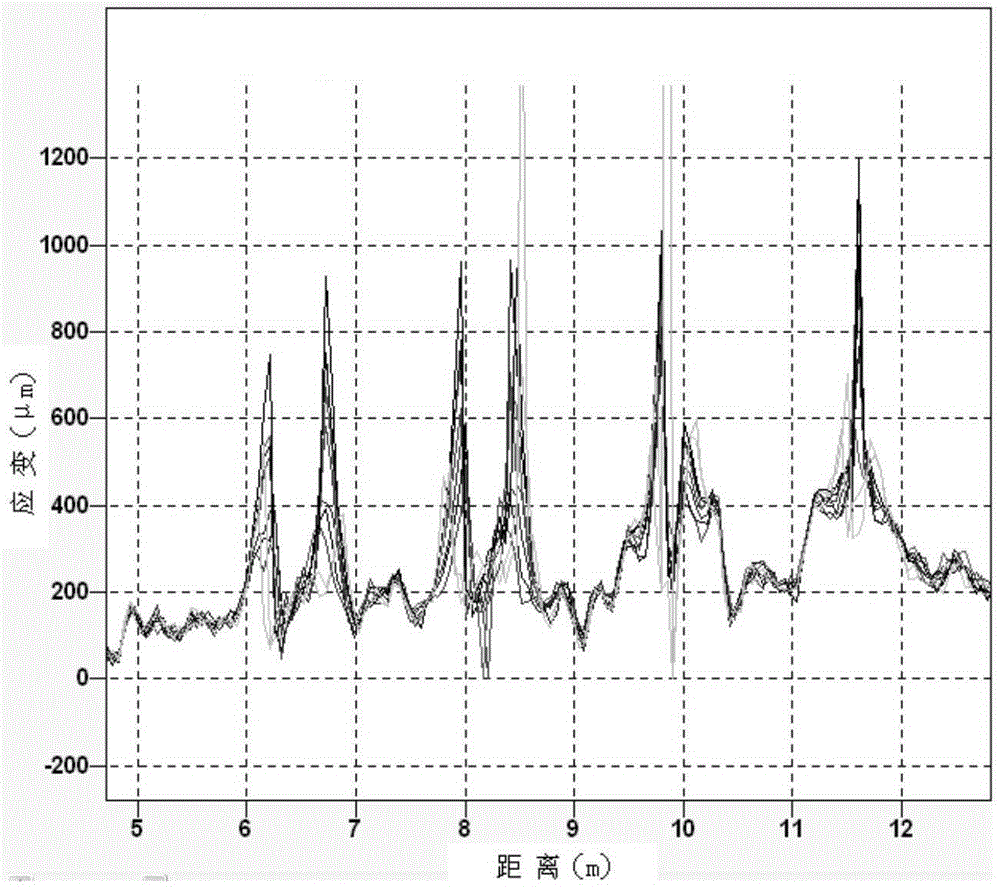

[0054] Specific Embodiments 1. A method for detecting the crack width of a concrete structure using an optical fiber sensor described in this embodiment is carried out in the following steps:

[0055] 1. The formula for calculating the crack width of concrete structures under theoretical conditions:

[0056] Theoretical conditions:

[0057](1) When cracks appear in the concrete structure, the positions on both sides of the crack will be unloaded, and the strain will become smaller;

[0058] (2) Assuming that a crack with a width of w is generated on the surface of the concrete structure, the strain on both sides of the crack is 0, and gradually increases toward the two sides of the crack as the distance from the crack increases. When the tensile strain at a certain point reaches the ultimate tensile strain, Then new cracks will appear at this time;

[0059] (3) The width of the crack in the concrete structure is w, and the length of the optical fiber slip section is L. Assum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com