Refractory fiber module and rapid construction method applying refractory fiber module

A technology of refractory fiber and construction method, which is applied in furnaces, integral lining, lining repair and other directions, can solve the problems of difficult to meet construction, affect construction period, and complicated construction, and achieve convenient and fast construction, simplified installation work, and high construction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

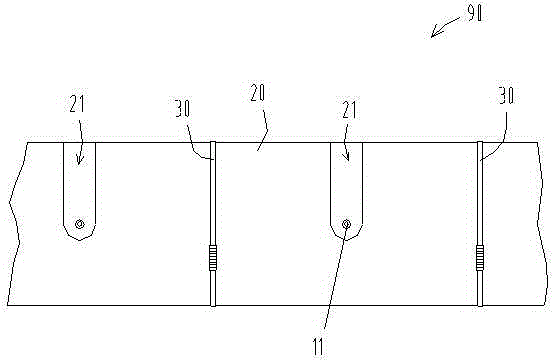

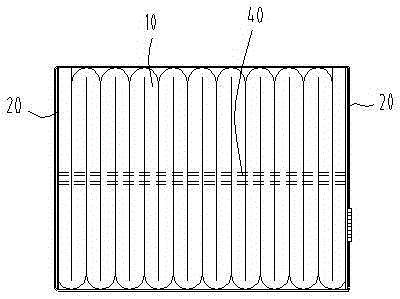

[0026] Such as figure 1 and 2 As shown, the refractory fiber module 90 is mainly made of fiber cotton 10 stacked and compressed, and two splints 20 are used on both sides of the compressed width direction to compress it, and it is packed tightly with a bandage 30, so that the pre-compressed The refractory fiber module can be made in a larger size. After the construction is completed, the bandage is untied and the splint is pulled away. The fiber cotton is expanded and fixed, which is easy to operate and easy to install.

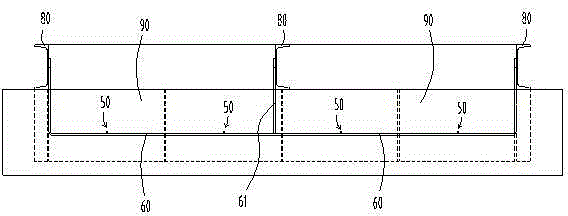

[0027] In the laying construction, linear fixing nails 50 and U-shaped fixing nails 60 are used to fix the refractory fiber module, and the fiber cotton 10 is provided with at least two through holes 11 running through the compressed width direction of the fiber cotton. It is used to penetrate the linear fixing nail 50. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com