tumbler for tea dryer

A technology of tea dryer and tumbler, which is applied in the direction of dryer, tea drying, drying, etc., which can solve problems such as uneven drying of tea, affecting tea quality, and affecting drying efficiency, so as to improve iron removal efficiency , save energy and improve drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

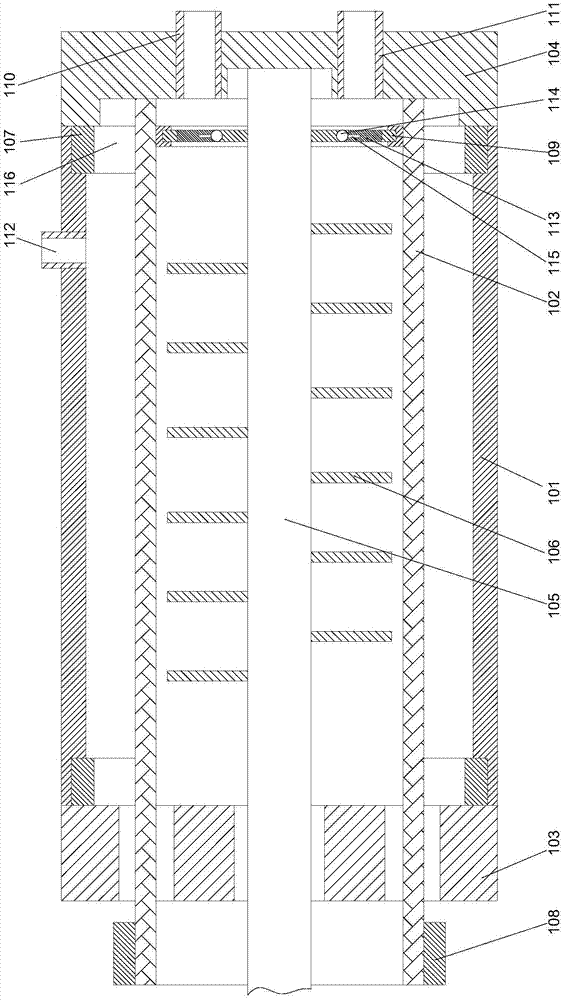

[0020] Such as figure 1 As shown, a tea dryer drum includes a hollow cylindrical housing 101 and a screen 102 arranged inside the housing 101. The screen 102 has a hollow cylindrical structure, and the housing The two ends of the body 101 are respectively provided with a left cover 103 and a right cover 104, and the two ends of the screen 102 are respectively rotatably connected to the left cover 103 and the right cover 104. The middle part is provided with a rotating shaft 105, and blades 106 are arranged on the rotating shaft 105, and the two ends of the rotating shaft 105 are respectively connected to the left cover 103 and the right cover 104 in rotation, and one end of the rotating shaft 105 runs through the The left cover 103, the end of the rotating shaft 105 is located outside the left cover 103, and the inner walls of the housing 101 near the two ends of the left cover 103 and the right cover 104 are respectively provided with The magnet 116 is provided with an input...

Embodiment 2

[0023] In this embodiment, on the basis of Embodiment 1, in order to facilitate the installation of magnets, in this embodiment, preferably, the inner walls of the two ends of the housing 101 close to the left cover 103 and the right cover 104 are respectively provided There is a ring-shaped fixed ring 107 , and a stepped groove is arranged on the inner wall of the fixed ring 107 , and the described magnet 116 is ring-shaped and fixedly connected in the stepped groove on the described fixed ring 107 .

[0024] In order to reduce the powder content in the tea leaves, in this implementation, preferably, one end of the screen 102 is rotatably connected to the right cover 104 through a bearing, and the screen 102 is far away from the right cover 104 One end passes through the left cover 103 , and the outer end surface of the screen 102 away from the right cover 104 is fitted with a ring gear 108 . By setting the ring gear, the ring gear can be driven to rotate by using the driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com