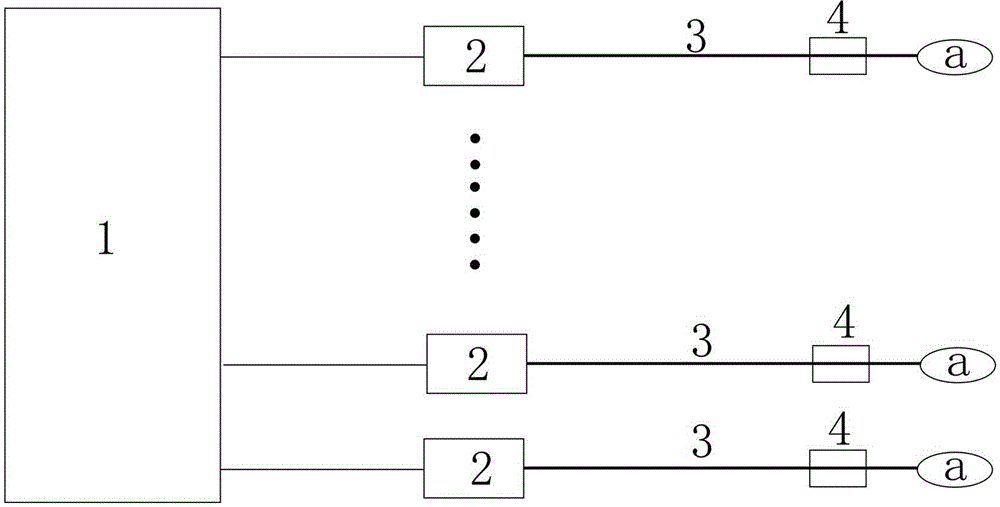

Entire shafting synchronous shaft automatic forced lubrication pressure device and method

A technology of forced lubrication and pressure device, applied in the direction of engine lubrication, lubricating parts, engine components, etc., can solve problems such as loss of stability, seizure, journal wear, etc., to avoid pollution and waste, uniform coverage, good The effect of lubrication maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

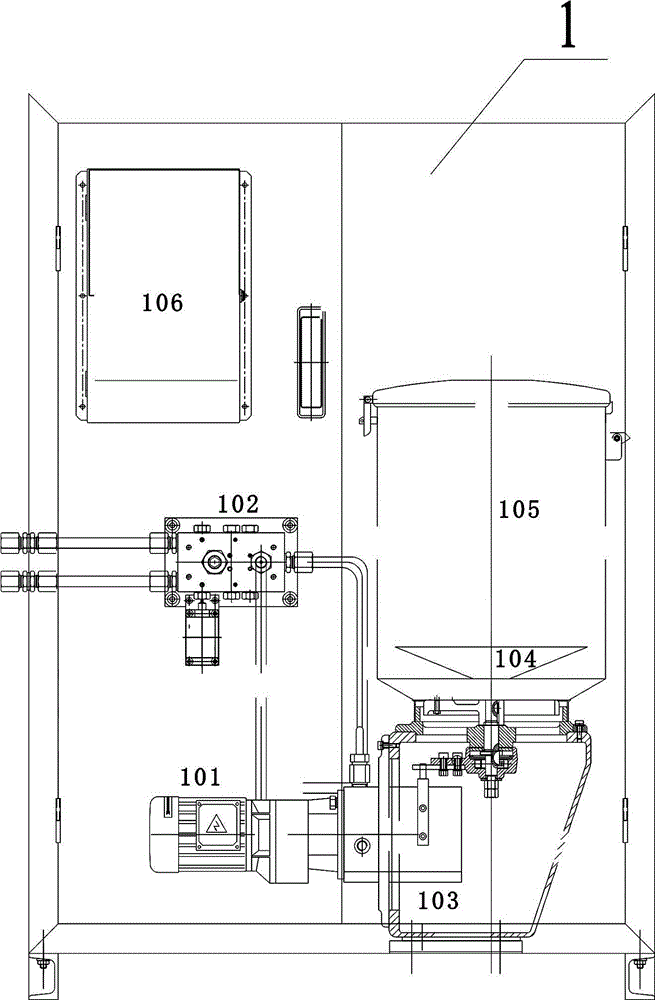

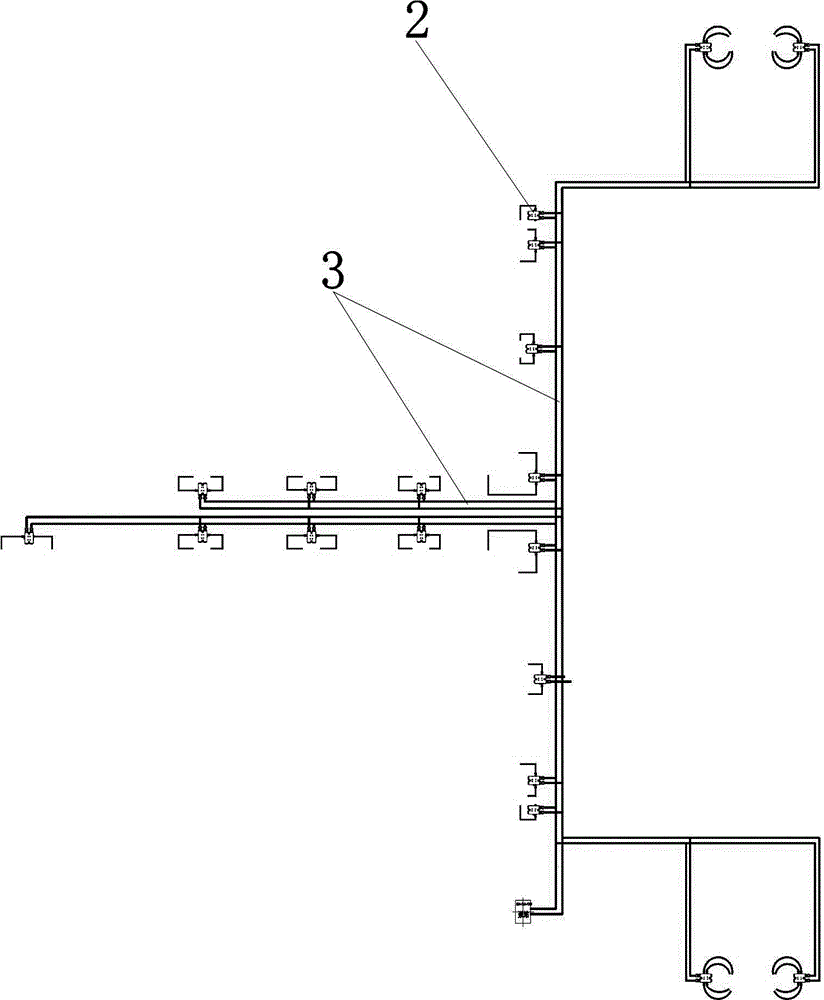

Method used

Image

Examples

specific Embodiment

[0047] Specific embodiment: when the ship cabin of the Three Gorges ship lift is in normal operation, the synchronization of the four sets of driving mechanisms is performed by the electrical synchronization control system. The function of the mechanical synchronous shaft system is: when any one or any two motors of the drive system fail, other normal motors will transmit power to the drive mechanism where the faulty motor is located, so that the cabin continues to safely run to the predetermined docking position. When the motor of one driving mechanism fails, the motors of the other three driving mechanisms provide driving torque to the failed unit at a substantially equal distance, so that the output of the motors in normal operation is balanced. This requires a good lubrication state between the journal and the bearing of the synchronous shaft of the ship's bearing box to ensure the stability and reliability of the output torque of the power unit of the ship lift.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com