Pipeline pulling machine

A kind of technology of pulling rope machine and pipeline, applied in the direction of pipe components, special pipes, mechanical equipment, etc., can solve the problems of lead wire breaking, increase cost, trouble, etc., and achieve the effect of simple structure and convenient lead wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

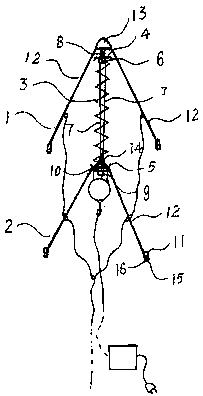

[0009] exist figure 1 In the middle, only the first rib 3 is set between the head umbrella 1 and the tail umbrella 2. The first rib adopts a reed, and the middle part of the reed is bent into a V shape. At least two second ribs have holes at the top of the V shape. , fixed with screw 4, after fixing, it becomes an umbrella shape, which can be expanded and contracted. The diameter of the screw head of the head umbrella is smaller than the diameter of the screw. Head nut cover 5. When installing, the screw head passes through the hole at the top of the second umbrella rib of the head umbrella, rests on the shoulder of the screw head, tightens and fixes it with the nut cover, and after tightening, the nut cover is placed on the umbrella tip of the head umbrella , the screw rear part 6 is in the umbrella, the rear screw end is connected to the spring upper seat 7, the upper part of the spring 8 is fixed below the spring upper seat, and the pulley 9 is fixed at the center of the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com