A RTO special valve for regenerative oxidation furnace

An oxidation furnace and regenerative technology, applied in the direction of incinerators, valve details, valve devices, etc., can solve the problems of environmental pollution and very high sealing performance requirements, and achieve good sealing effect, long service life and prevent leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

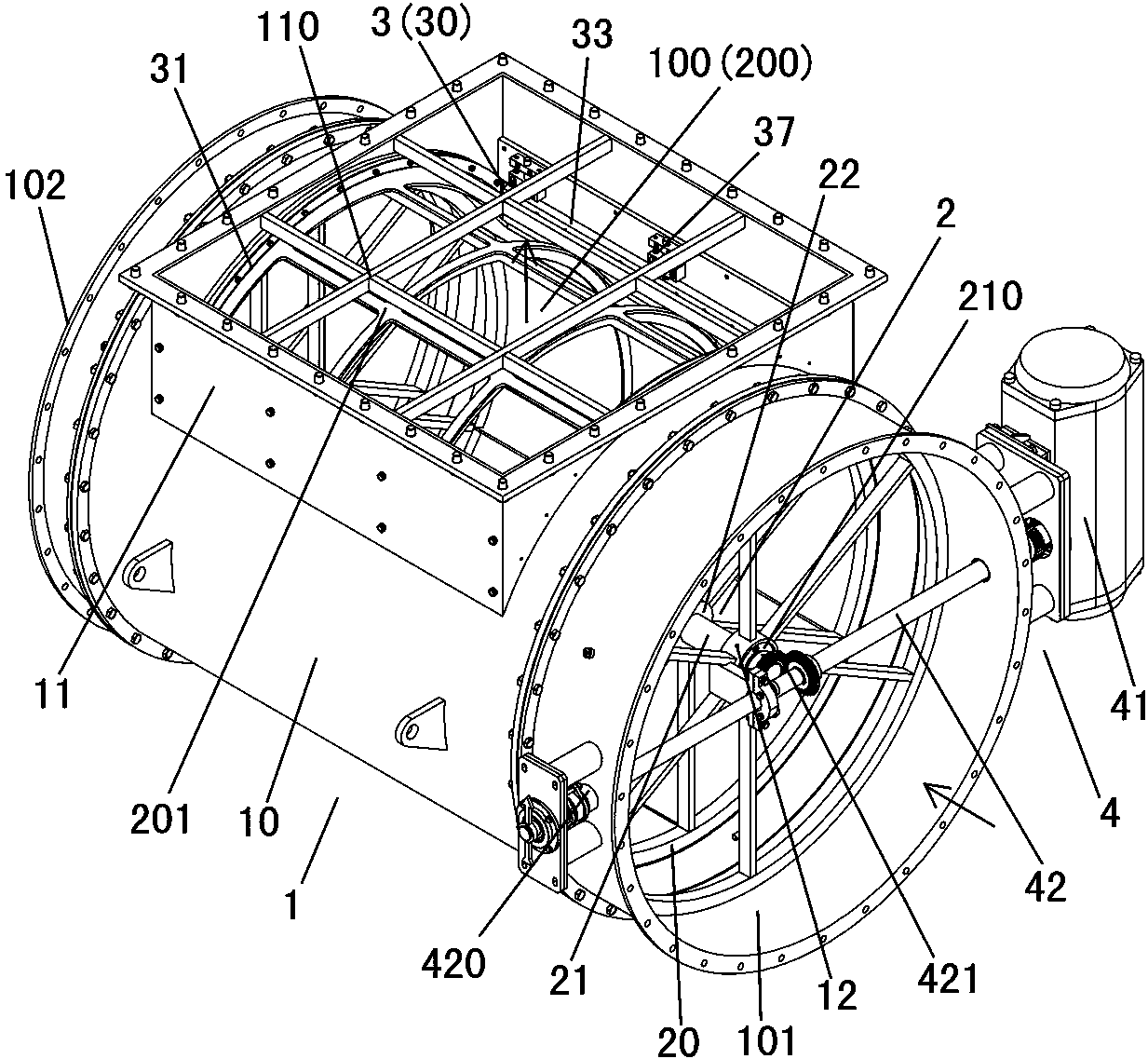

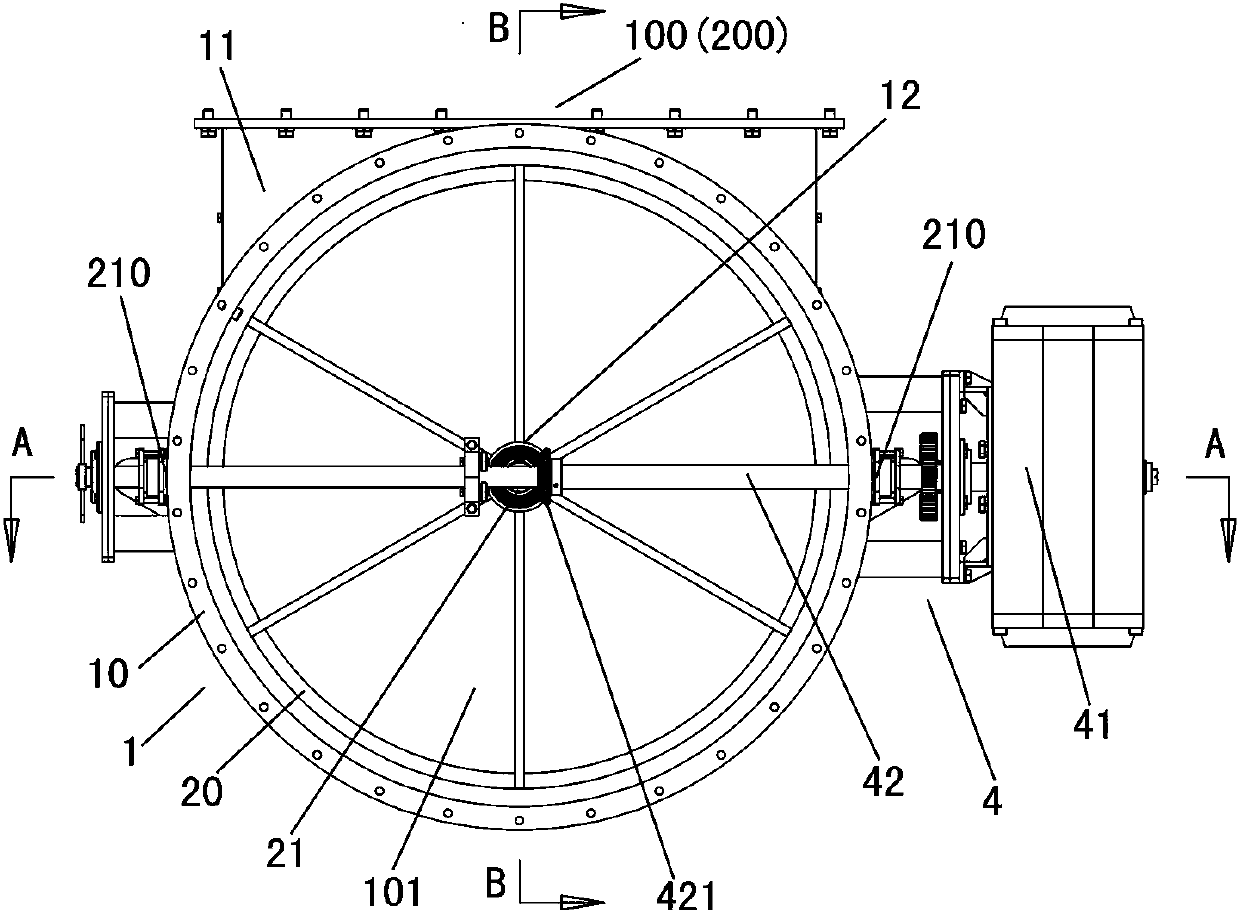

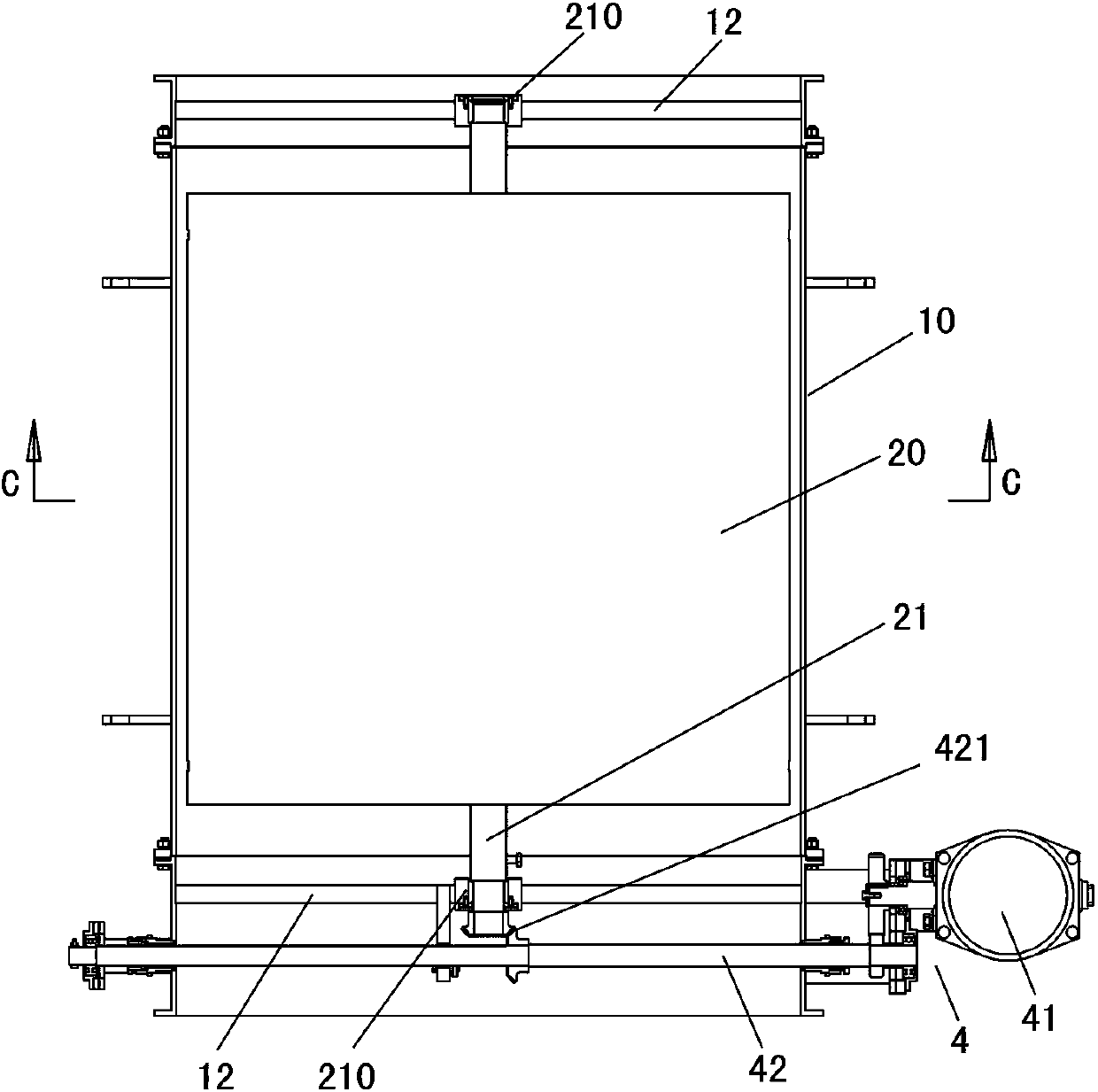

[0063] Such as Figure 1 to Figure 10 As shown, the special valve for regenerative oxidation furnace RTO in this preferred embodiment includes a valve body mechanism 1 , a rotary valve core mechanism 2 , a sealing mechanism 3 and a switch control mechanism 4 .

[0064] The above valve body mechanism 1 includes a valve body 10, an air outlet connecting pipe 11 and two mandrel mounting frames 12;

[0065] The above-mentioned valve body 10 is cylindrical, and one end 101 of the above-mentioned valve body 10 is an air inlet, and the other end 102 of the above-mentioned valve body 10 is closed or communicated with the air inlet of another regenerative oxidation furnace RTO special valve. An air outlet 100 is provided on the side of the body 10;

[0066] The above-mentioned air outlet connecting pipe 11 adopts a square pipe, and the above-mentioned air outlet connecting pipe 11 is arranged on the air outlet 100; the above-mentioned air outlet connecting pipe 11 is provided with a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com