Gearbox with 10 forward gears and 10 reversing gears

A gearbox and gear position technology, which is applied in the field of gearboxes, can solve the problems of accelerated gear shift tooth end surface damage, unstable shifting process, and impact of shifting elements, etc., to achieve improved operating comfort, compact structure, and easy shifting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

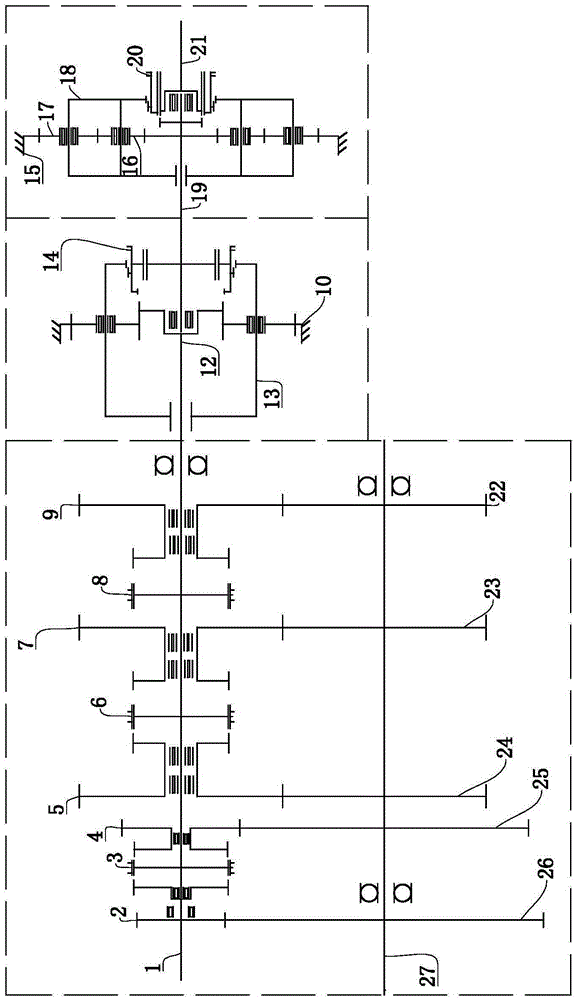

[0014] Such as figure 1 As shown, a 10+10-gear gearbox is used on tractors or other similar motor vehicles. It realizes 10 forward gears and 10 gears through sequentially arranged main transmission mechanism, high-low gear transmission mechanism and front and rear gear transmission mechanism. a reverse gear.

[0015] The main structure of the main transmission mechanism is as follows:

[0016] The first shaft 1 is rotatably mounted on the box body of the gearbox through bearings. The constant meshing driving gear 2 is fixedly installed on the first shaft 1. One end of the first shaft 1 is the power input end, and the other end of the synchronizer connection end is provided with 4th and 5th gear synchronizer 3 Coordinated external teeth.

[0017] The second shaft 12 is arranged coaxially with the first shaft 1, and one end of the second shaft 12 is mounted on the synchronizer connection end of the first shaft 1 through bearing rotation, and the other end is mounted on the cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com