Carrying skip bucket for forklift

A technology for forklifts and mounting plates, applied in the direction of lifting devices, etc., can solve problems such as inability to adjust, and achieve the effect of volume adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below, the technical solution of the present invention will be described in detail through specific examples.

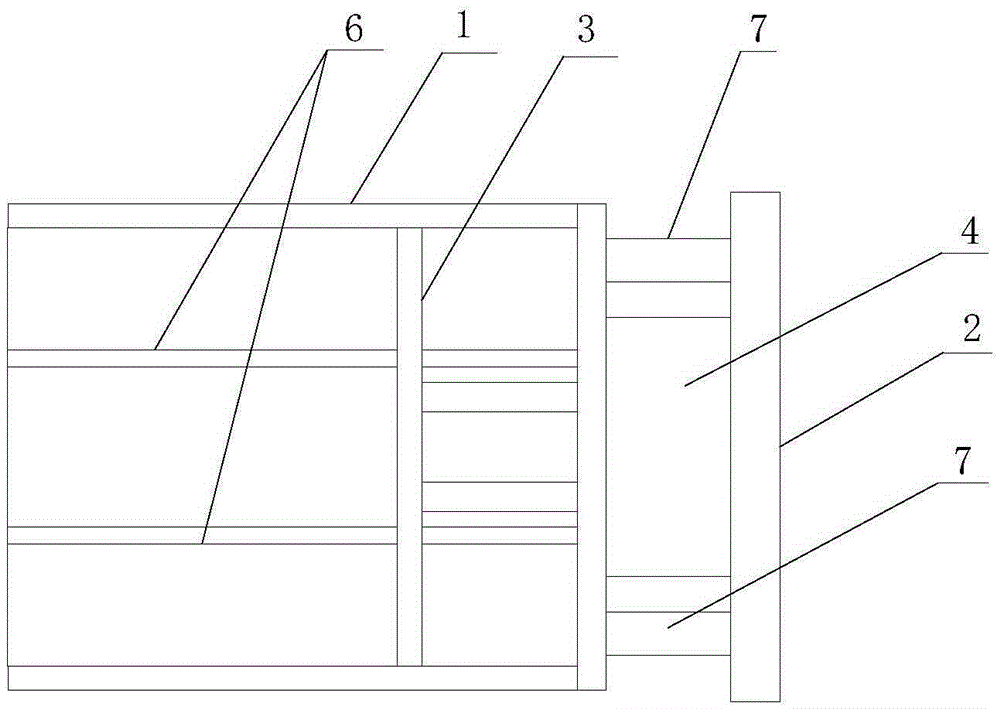

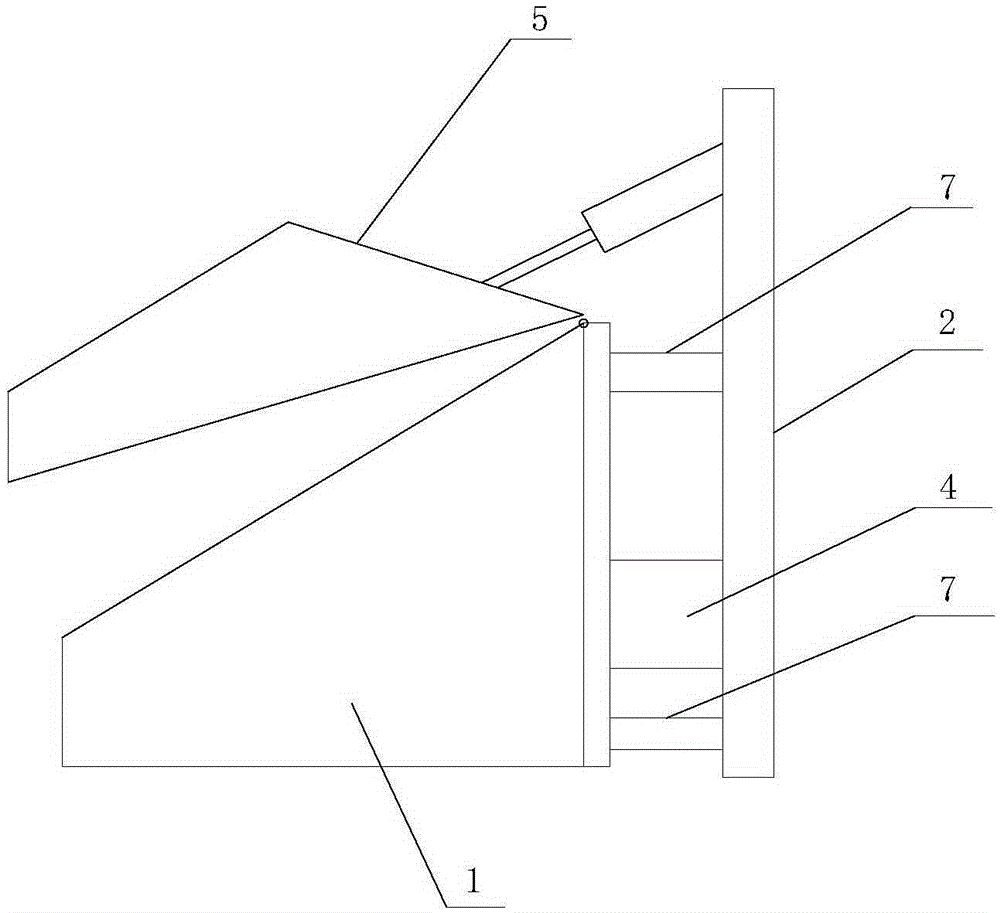

[0027] Such as Figure 1-2 as shown, figure 1 It is a structural schematic diagram of a transport dump for a forklift proposed by the present invention; figure 2 It is a side view of a transport dump for a forklift proposed by the present invention.

[0028] refer to Figure 1-2 , a forklift handling dump proposed by the embodiment of the present invention includes: a dump body 1, a mounting plate 2, a pushing plate 3 and a cylinder 4, wherein:

[0029] One side of the mounting plate 2 is provided with an assembly for forklift assembly;

[0030] The tipping bucket body 1 is located on the side of the mounting plate 2 away from the assembly parts, and there is a gap reserved between the tipping bucket body 1 and the mounting plate 2. The tipping bucket body 1 is connected to the mounting plate 2 through the connector 7. The tipping bucket body 1 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com