Press-fitting equipment for pointers of stepper motor combined instrument

A combination instrument pointer and stepping motor technology, applied in hand-held tools, manufacturing tools, etc., can solve the problem that the U-shaped line unit is not equipped with a pointer material box, the stepping motor cannot return to the mechanical zero position, and the dial cannot be returned Zero position and other issues, to achieve the effect of compact structure, reasonable orientation and positioning, and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the utility model is described in further detail.

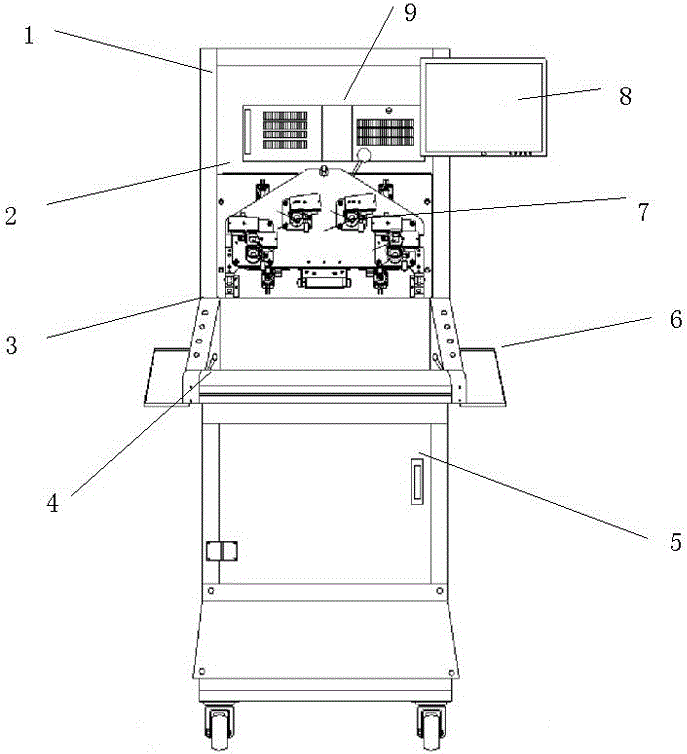

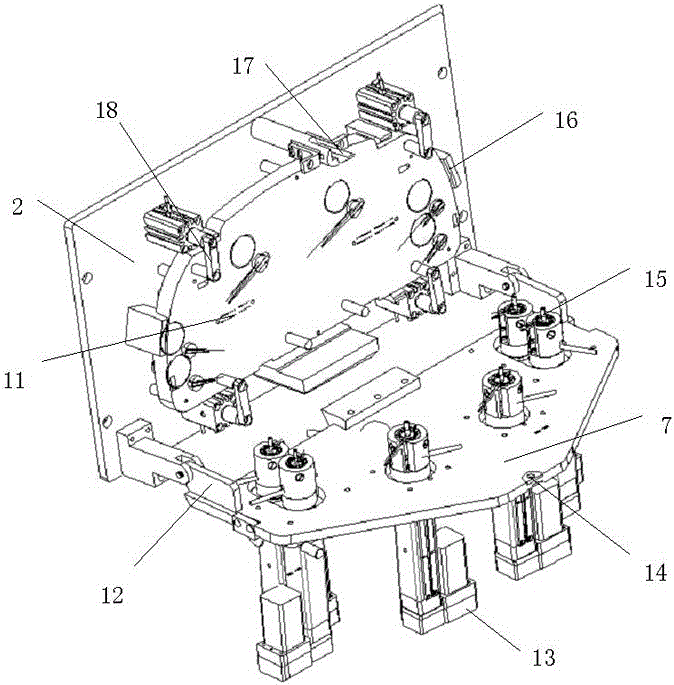

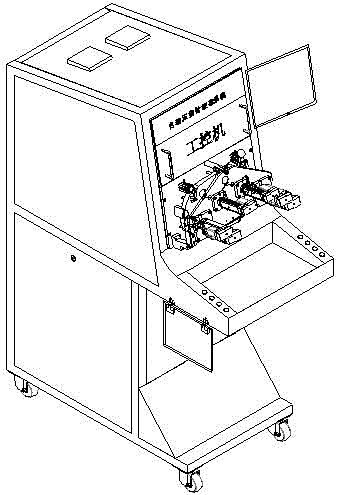

[0017] Such as figure 1 , image 3 As shown, the pointer press-fitting equipment for the stepper motor combined instrument consists of three layers of main frame 1, industrial computer 9, liquid crystal display 8, fixture upper mold 2, fixture lower mold 7, operation button 3, pointer tray 6, and control keyboard 4 , Electric control box main body 5, power supply, PLC, pneumatic control unit module, voltage source, resistance signal, CAN signal. The industrial computer 9 and the liquid crystal display 8 are installed on the first layer of the main frame 1 . The fixture upper mold 2 and the fixture lower mold 7 are installed on the second layer of the main body frame 1, and the pointer tray 6 is installed on both sides of the fixture lower mold 7, such as figure 1 Shown pointer tray 6 is open working state, as image 3 The pointer tray 6 shown is in a closed and folded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com