Reaction kettle container

A technology of reactor and reactor body, which is applied in the field of fixed reactors, can solve problems such as easy blockage of the discharge pipe, and achieve a good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

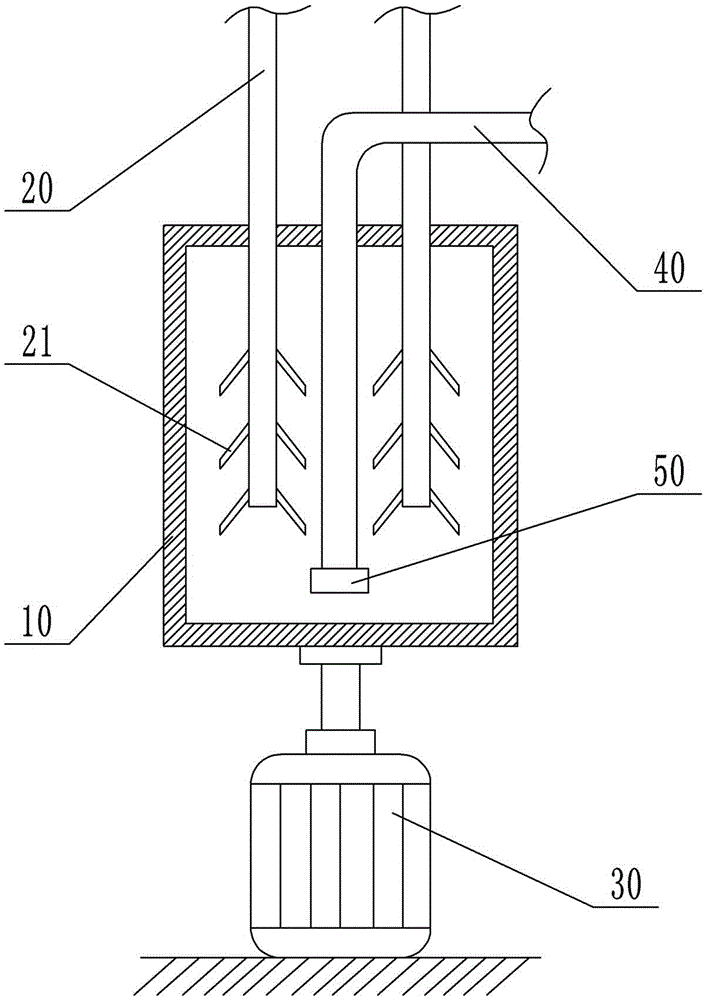

[0014] The reference signs in the accompanying drawings of the specification include: the reaction kettle body 10 , the stirring shaft 20 , the stirring blade 21 , the driving motor 30 , the liquid outlet pipe 40 , and the filter screen 50 .

[0015] Such as figure 1 As shown, the reactor container includes a reactor body 10 , a stirring shaft 20 and a stirring blade 21 . The stirring shaft 20 is located in the reactor and is coaxially connected with the reactor body 10 , and the stirring blade 21 is welded on the stirring shaft 20 . The stirring shaft 20 and the stirring rod form a stirring device, and the number of the stirring device is two. In addition, this solution also includes a liquid outlet pipe 40 and a drive motor 30. The reaction kettle body 10 is rotated and installed on the drive motor 30. The drive motor 30 is a servo motor. Compared with ordinary motors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com