Online demister

A demister and body technology, applied in the field of demister devices, can solve the problems of loss of demister effect, poor removal ability, pressure drop, etc., and achieve the effects of reduced maintenance cost, convenient cleaning and high foam breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

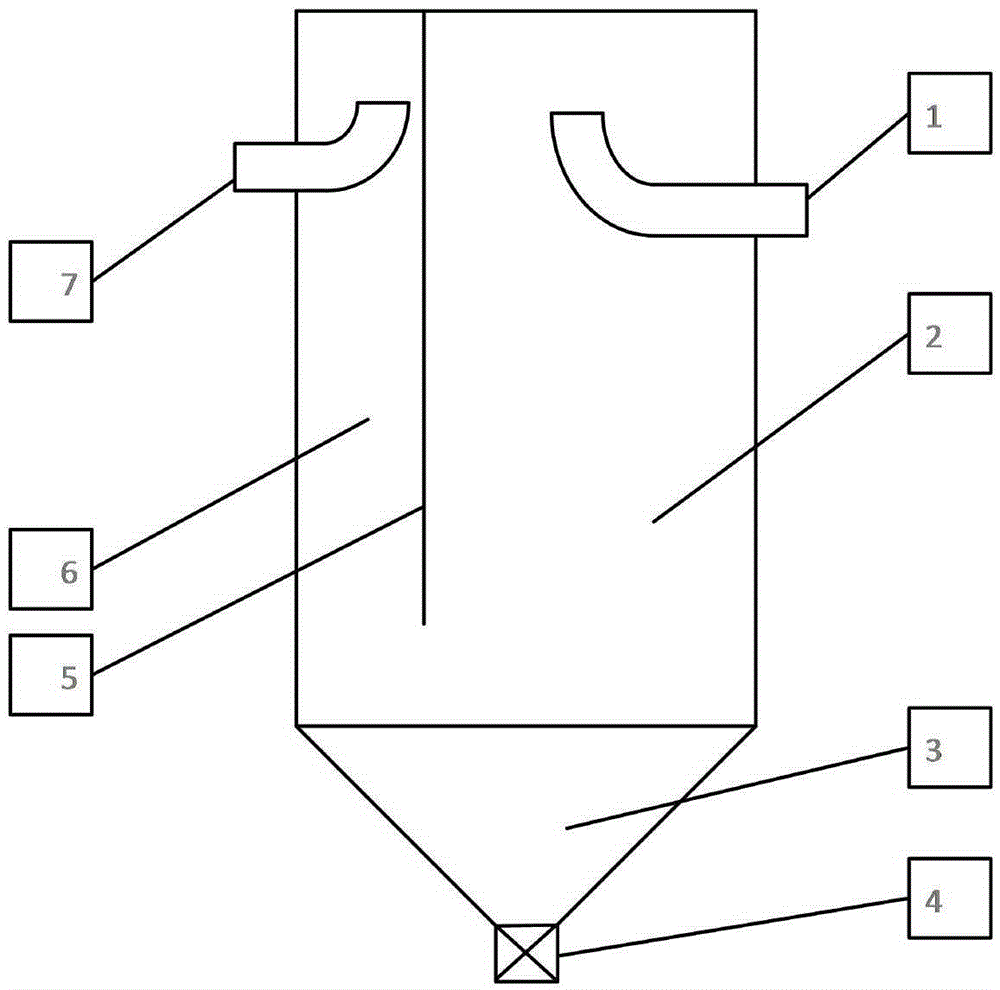

[0024] see figure 1 , is a preferred embodiment of the online demister, including a demister body with a hollow structure, and an isolation plate 5 is erected in the inner cavity of the demister body, and the isolation plate 5 divides the inner cavity of the body It is divided into a separation space 2 and an airflow space 6, and the volume of the separation space 2 is larger than that of the airflow space 6. There is a channel for air flow to pass between the separation plate 5 and the bottom of the demister body, and the part corresponding to the side wall of the demister body and the separation space 2 is provided with an air inlet pipe 1, and the demister body The part of the side wall corresponding to the airflow space 6 is provided with an air outlet pipe 7 . The air inlet pipe 1 and the air outlet pipe 7 are all located on the top of the demister body. The inlet pipe 1 and the outlet pipe 7 are relatively arranged on the side wall of the demister body. The parts of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com