OLED device, OLED device manufacturing method and display

A technology of devices and device layers, applied in the field of OLED devices and their preparation methods and displays, can solve the problems of pixel shrinkage and impact on service life, and achieve the effects of solving pixel shrinkage, prolonging service life, and avoiding gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

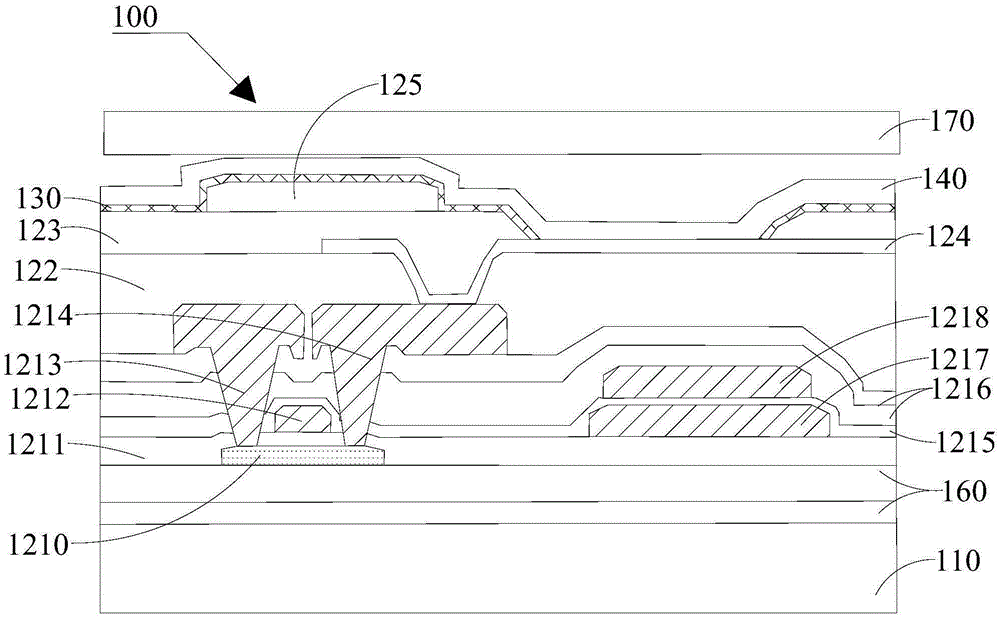

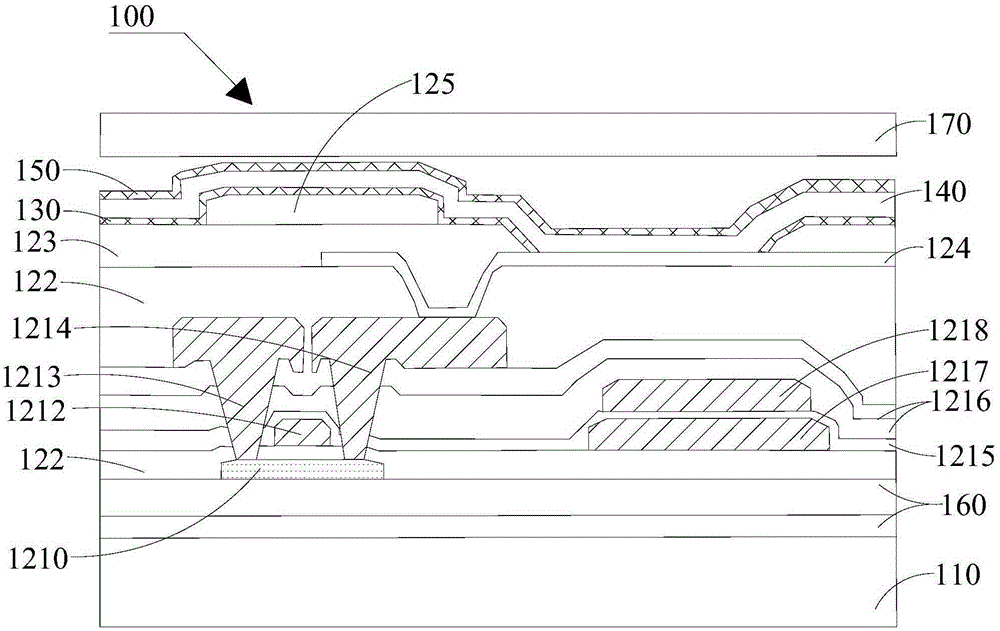

[0029] In order to make the technical solution of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and specific embodiments.

[0030] First, it should be noted that the functional layer refers to a TFT (Thin Film Transistor, thin film transistor) layer formed on a substrate. It can specifically include a gate, a source, a drain, and an active layer. It may also include a planarization layer, a pixel defining layer, and support pillars or isolation pillars.

[0031] The OLED device layer specifically includes a first organic layer and a cathode sequentially formed on the first water-absorbing layer. Generally, it may also include a second organic layer formed on the cathode.

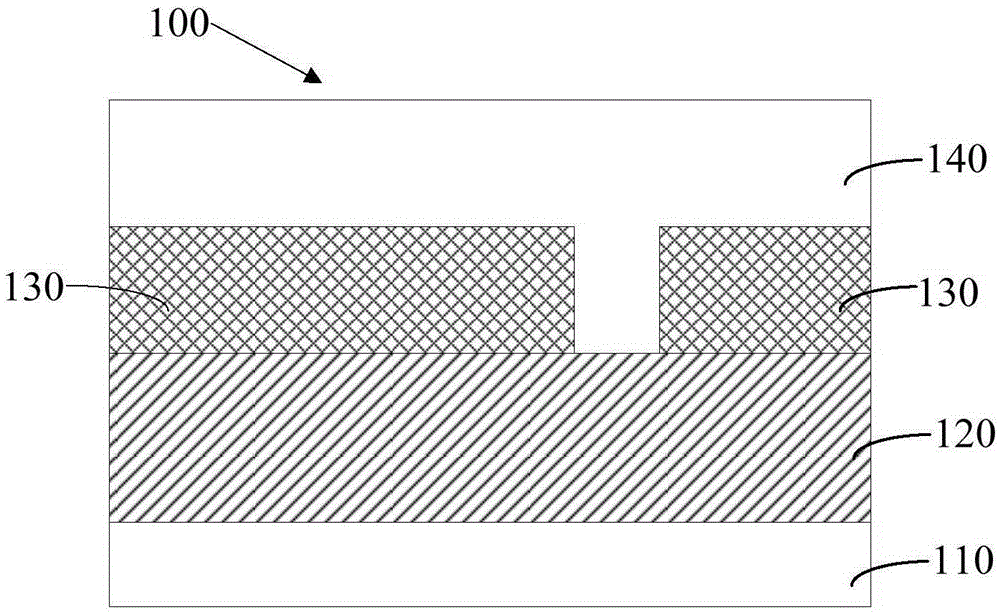

[0032] Among them, see figure 1 As a specific embodiment of the OLED device 100 of the present invention, that is, the first embodiment, it includes a substrate 110, a functional layer 120 formed on the substrate 110, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com