Adaptive material requirement plan (MRP) calculation method

A technology of material requirement planning and calculation method, applied in the direction of calculation, logistics, data processing application, etc., can solve the problems of inability to track the MRP process, difficult for users to understand, and large amount of calculation, so as to increase flexibility and reusability , easy to update and maintain, improve system efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

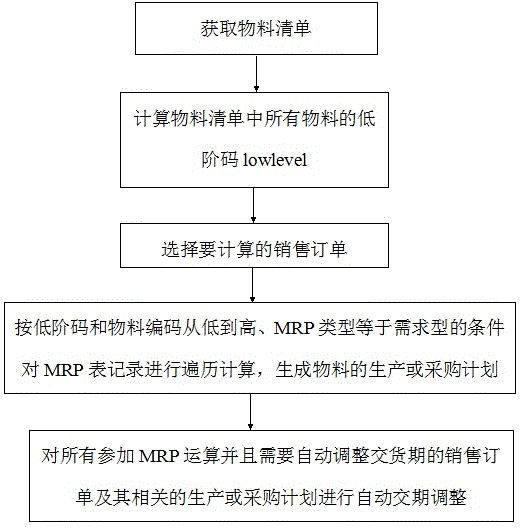

[0068] Example: such as figure 1 As shown, an adaptive material requirements planning calculation method, including:

[0069] S1. Obtain a list of materials;

[0070] S2. Calculate the low-level code lowlevel of all materials in the material list;

[0071] S3. Select the sales order to be calculated;

[0072] S4. According to the conditions of low-level code and material code from low to high, MRP type is equal to demand type, traverse and calculate the MRP table records, and generate the production or purchase plan of the material;

[0073] S5. Perform automatic delivery adjustment on all sales orders and related production or purchase plans that participate in the MRP calculation and need to automatically adjust the delivery date.

[0074] Not all sales orders of the production company need to arrange production immediately, so you can only select "Sales Orders to be Calculated" for calculation. For each sales order, you can set whether to allow automatic delivery adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com